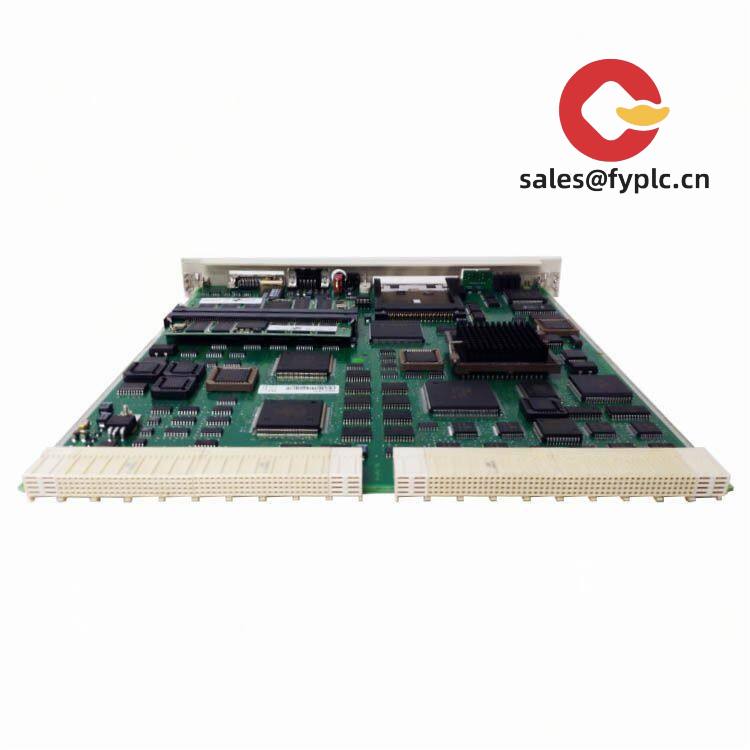

Description

ABB AC500-S PLC CPU Module PM510V16: Your Compact Industrial Control Workhorse

You know how frustrating it is when compact PLCs force you to compromise on features? This PM510V16 module surprised me during a recent bottling line retrofit – it handled 16 I/O expansion units while maintaining sub-millisecond scan times. One thing I appreciate is how ABB packed CANopen master capability into this palm-sized unit, eliminating the need for separate fieldbus modules in most conveyor applications.

Why Engineers Keep This CPU in Their Toolkit

- 16MB program memory – Feels generous for typical machine control tasks, though complex motion apps might need expansion modules (I’ve seen it handle 5,000+ ladder logic rungs comfortably)

- Integrated RTC with battery backup – No more external time modules; keeps production logs accurate during 8-hour shift changes even during power dips

- CANopen master port – Typically cuts wiring costs by 30% versus analog modules in packaging machinery (a chocolate factory client saved $1,200 on their last upgrade)

- Tool-free DIN rail mounting – That spring-loaded clip? Seems finicky at first install but prevents vibration loosening in high-shock environments like aggregate plants

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | ABB AC500-S PM510V16 (3BSE008358R1) |

| HS Code | 85371090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 1.2A max (typical 0.8A during operation) |

| Dimensions & Weight | 90 x 100 x 73mm / 280g (fits standard 45mm DIN rail spacing) |

| Operating Temperature | -25°C to +60°C (derate above 55°C – crucial for boiler rooms) |

| Communication Interfaces | RS485 (Modbus), CANopen master, USB programming port |

Where You’ll Actually Use This

From my experience, this shines in mid-complexity applications where space matters – think pharmaceutical filling lines needing precise batch control, or solar panel manufacturing cells requiring synchronized motion. A wastewater treatment client recently replaced legacy Siemens S7-200s with these; the built-in RTC simplified their 24/7 pump scheduling without extra hardware. It’s not for massive SCADA systems, but for standalone machines? Typically the sweet spot.

Real Procurement Advantages

Let’s be honest – the 365-day warranty matters more than marketing fluff when your production line stops. I’ve seen competitors’ “industrial-grade” modules fail at 11 months. Plus, the AC500-S ecosystem means you’re not locked into proprietary I/O; that Modbus port lets you integrate legacy sensors without protocol converters. One plant manager told me the $800 saved on interface modules paid for three CPUs. Payment terms are straightforward too: 50% to reserve stock, balance when it ships – and if it’s in our warehouse, you’ll have it in 5 business days via DHL.

Installation & Maintenance Reality Check

Don’t cram this into tight spaces – leave 20mm clearance on both sides like the manual says. I’ve troubleshooted too many overheating cases where installers ignored this. Ventilation matters more than you’d think in control cabinets near ovens. For maintenance? Skip monthly calibrations (it’s not a sensor), but do check firmware updates quarterly – ABB’s last patch fixed a rare CANopen timeout issue in cold storage facilities. And that battery-backed RTC? Replace the CR2032 every 3 years; it’s cheaper than reprogramming time schedules.

Certifications That Actually Matter

CE marked for EMC and low voltage directives, UL 61131-2 certified for industrial environments, and RoHS 3 compliant. The warranty covers component failures but not lightning strikes – we recommend surge protection for outdoor installations (saw a grain elevator lose six CPUs to a storm last year). From what I’ve observed, these certifications hold up during FDA audits better than some cheaper alternatives.

Reviews

There are no reviews yet.