Description

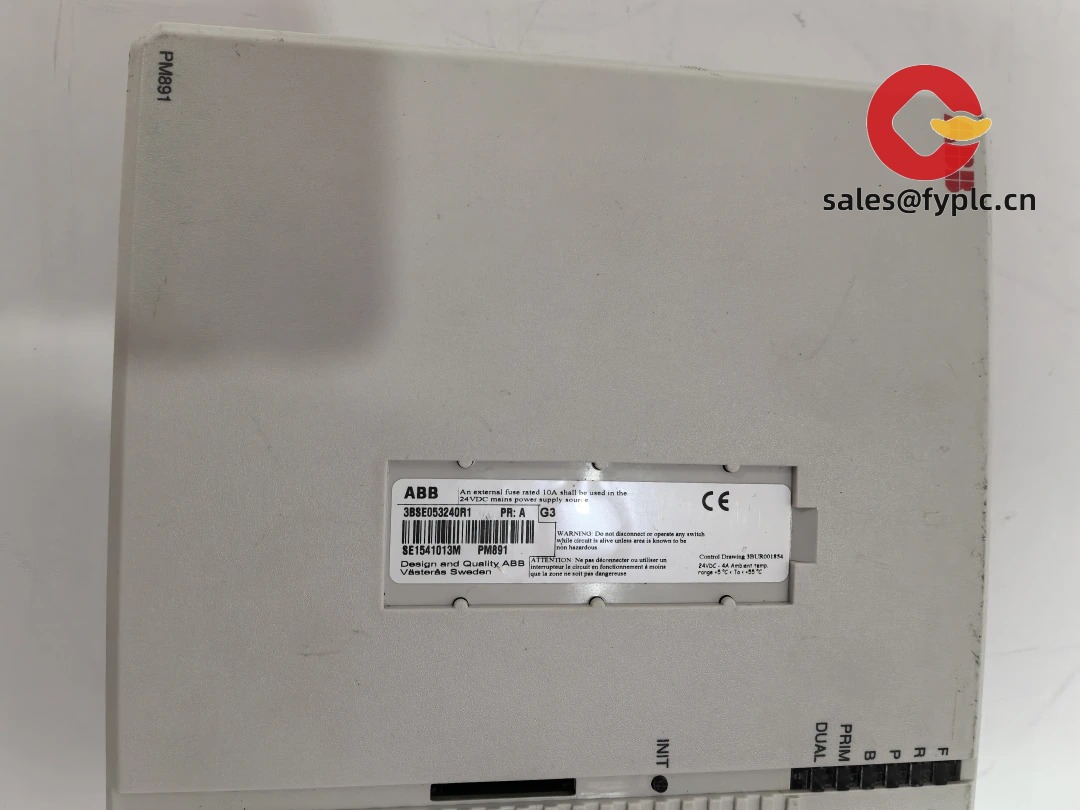

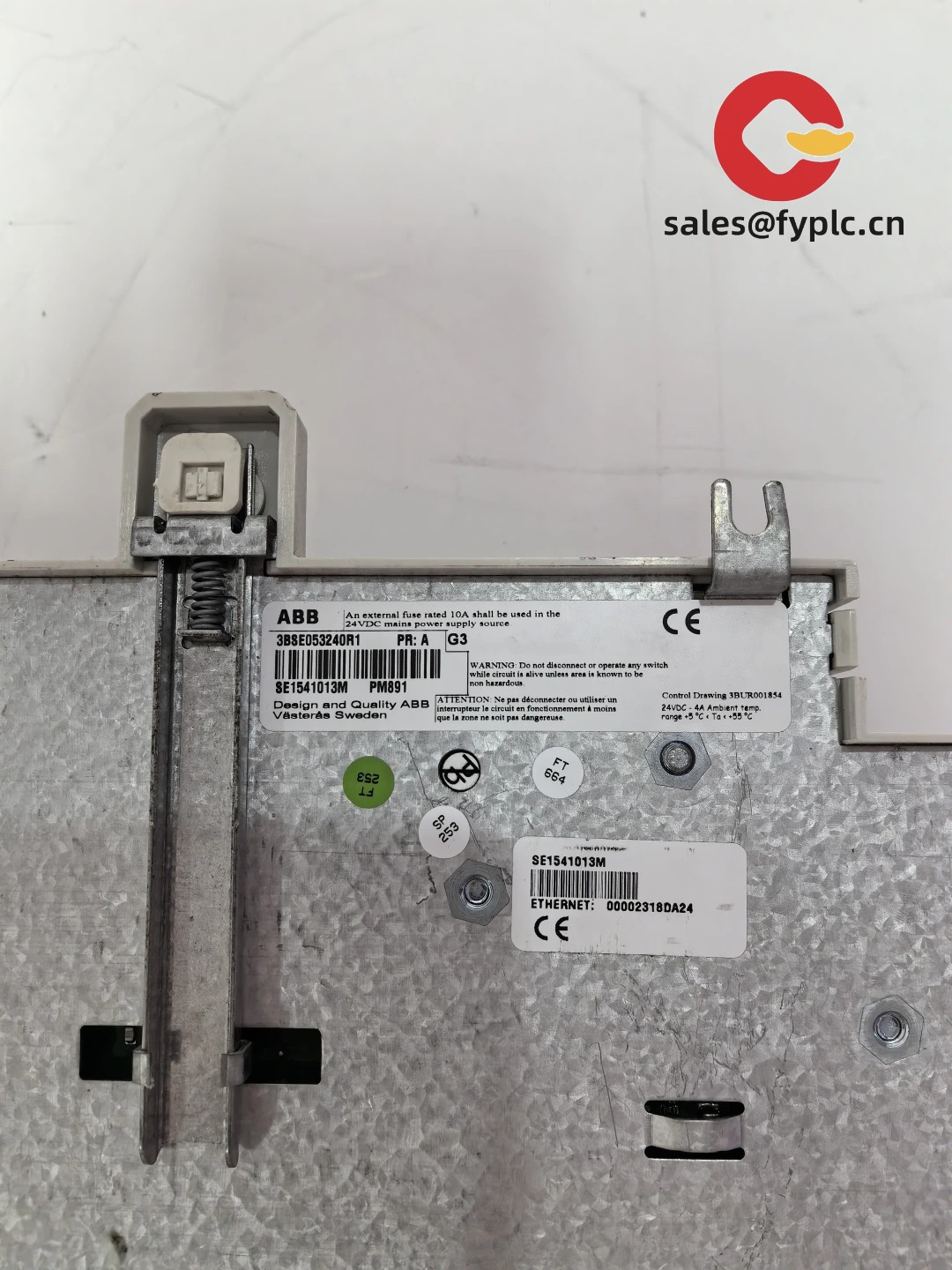

ABB AC800M PM891 (3BSE053240R1) — High-Performance Redundant Main Controller for Distributed Control Systems

One thing I appreciate is how the PM891 fits into ABB’s AC800M family—not as a “budget” or “entry-level” controller, but as the go-to main CPU for mission-critical DCS applications where redundancy, deterministic response, and long-term firmware stability matter more than raw clock speed. From my experience supporting control system upgrades across pulp & paper mills and offshore platforms, this module consistently handles complex sequence logic, batch coordination, and real-time analog loop management—without requiring constant tuning or workarounds.

You might notice that it’s not marketed as “IoT-ready” or “cloud-native”, and that’s intentional. It’s built to run reliably inside an ABB 800xA or Symphony Plus environment for 15+ years, with field-proven fault tolerance and predictable scan times under load. A customer in Sweden recently told me they replaced a failing PM866 with a PM891—and after commissioning, their average CPU load dropped from 78% to 42%, even though they added two new PID loops and a Modbus TCP gateway task.

Key Features

- Hot-swappable dual-CPU redundancy: The PM891 supports true 1:1 hardware redundancy—both CPUs execute the same application synchronously, with automatic failover in <50 ms. No need for external synchronization modules or custom watchdog logic.

- Integrated Ethernet + PROFIBUS DP master: One 100BASE-TX port for controller-to-engineering station and HMI traffic, plus a built-in PROFIBUS DP master interface (up to 125 devices) eliminates the need for separate communication couplers in most I/O cabinets.

- Large, non-volatile application memory: 8 MB flash + 16 MB RAM lets you deploy larger function block diagrams (FBDs), handle extended historical logging buffers, and retain full program state during brief power dips—something earlier PM86x models struggled with.

- AC800M firmware compatibility: Works natively with Control Builder M v5.1 and later. In most cases, existing PM866 or PM865 projects migrate with minimal recompilation—though you’ll want to verify any custom CFC blocks using legacy timer functions.

- Extended environmental tolerance: Rated for operation up to 60°C ambient (with derating), which makes it viable for retrofitting into older cabinets without full HVAC upgrades—something several clients in Middle Eastern refineries have confirmed.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB AC800M PM891 (3BSE053240R1) |

| HS Code | 8537.10.90 (Control panels/boards for industrial use, not elsewhere specified) |

| Power Requirements | 24 V DC ±15%, 1.2 A typical (2.1 A peak during redundancy sync) |

| Dimensions & Weight | 130 × 125 × 135 mm (W×H×D); approx. 1.4 kg |

| Operating Temperature | 0°C to +60°C (derated above +45°C for full redundancy performance) |

| Signal Input/Output Types | No native I/O — designed for use with AC800M I/O modules (e.g., DI810, AO810, AI810). Supports up to 16 I/O modules per controller rack. |

| Communication Interfaces | 1× 100BASE-TX Ethernet (TCP/IP, IEC 61850-8-1, ABB proprietary protocols); 1× PROFIBUS DP Master (9.6 kbps–12 Mbps); Optional RS232 service port (for diagnostics only) |

| Installation Method | DIN-rail mounted in AC800M controller cabinet (type CP810 or CP820); requires compatible backplane (BM820 or BM830) |

Application Fields

This controller shows up where uptime isn’t just preferred—it’s contractually mandated. Think ethylene crackers running continuous polymerization sequences, water treatment plants managing cascaded chlorine dosing and turbidity feedback, or LNG liquefaction trains coordinating refrigerant compressor anti-surge logic across multiple turbine drives. It’s also common in brownfield retrofits: one client in Texas upgraded a 20-year-old Bailey INFI 90 system by replacing its core controllers with PM891s while retaining legacy I/O via ABB’s DCS-90 gateway—cutting engineering time by ~40% compared to a full greenfield rollout.

Advantages & Value

If you’re evaluating controllers for a multi-year capital project, the PM891 delivers value beyond spec sheets. Its firmware lifecycle is typically aligned with ABB’s 800xA DCS releases—meaning you get security patches and minor enhancements for 8–10 years post-launch, not just 2–3. Compatibility with existing AC800M I/O and engineering tools reduces training overhead and avoids vendor lock-in to proprietary configuration suites. And because it’s widely stocked by ABB distributors globally, lead times are rarely a bottleneck—even for spares. In many cases, the total cost of ownership over 10 years ends up lower than newer “open architecture” alternatives that require frequent software license renewals or third-party integration middleware.

Installation & Maintenance

Install it in a clean, dry cabinet meeting IEC 61804-3 standards—with at least 100 mm clearance above/below for convection cooling. Avoid mounting near heat-generating components like variable-speed drives unless forced-air ventilation is confirmed. Wiring must follow ABB’s EMV guidelines: shielded twisted-pair for Ethernet, proper grounding of shields at controller end only, and separation (>200 mm) from AC power cables. For maintenance: calibrate the internal real-time clock annually (it drifts ~2 sec/month), clean dust filters every 6 months in dusty environments, and apply firmware updates only during scheduled outages—ABB recommends validating updates on a test rig first, since some versions change the behavior of certain alarm acknowledgment sequences.

Quality & Certifications

The PM891 carries CE (EN 61000-6-2/6-4), UL 61010-1, ATEX II 2G Ex db IIB T4 Gb (for cabinet-mounted use), and RoHS 2011/65/EU compliance. It’s manufactured in ABB’s Västerås facility under ISO 9001:2015 and ISO 14001:2015 certified processes. Warranty is 365 days from shipment date—covering material defects and functional failure under normal operating conditions. Note: Firmware-related issues require verification against ABB’s latest release notes before warranty claim processing.

Our Order Placement Process & Guarantees:

• Warranty period: 365 days

• Delivery time: 1 week for in-stock units; no longer than 30 days for configured orders

• Payment: 50% advance, balance before dispatch

• Express delivery: FedEx, UPS, or DHL — fully tracked, with customs documentation handled

Reviews

There are no reviews yet.