Description

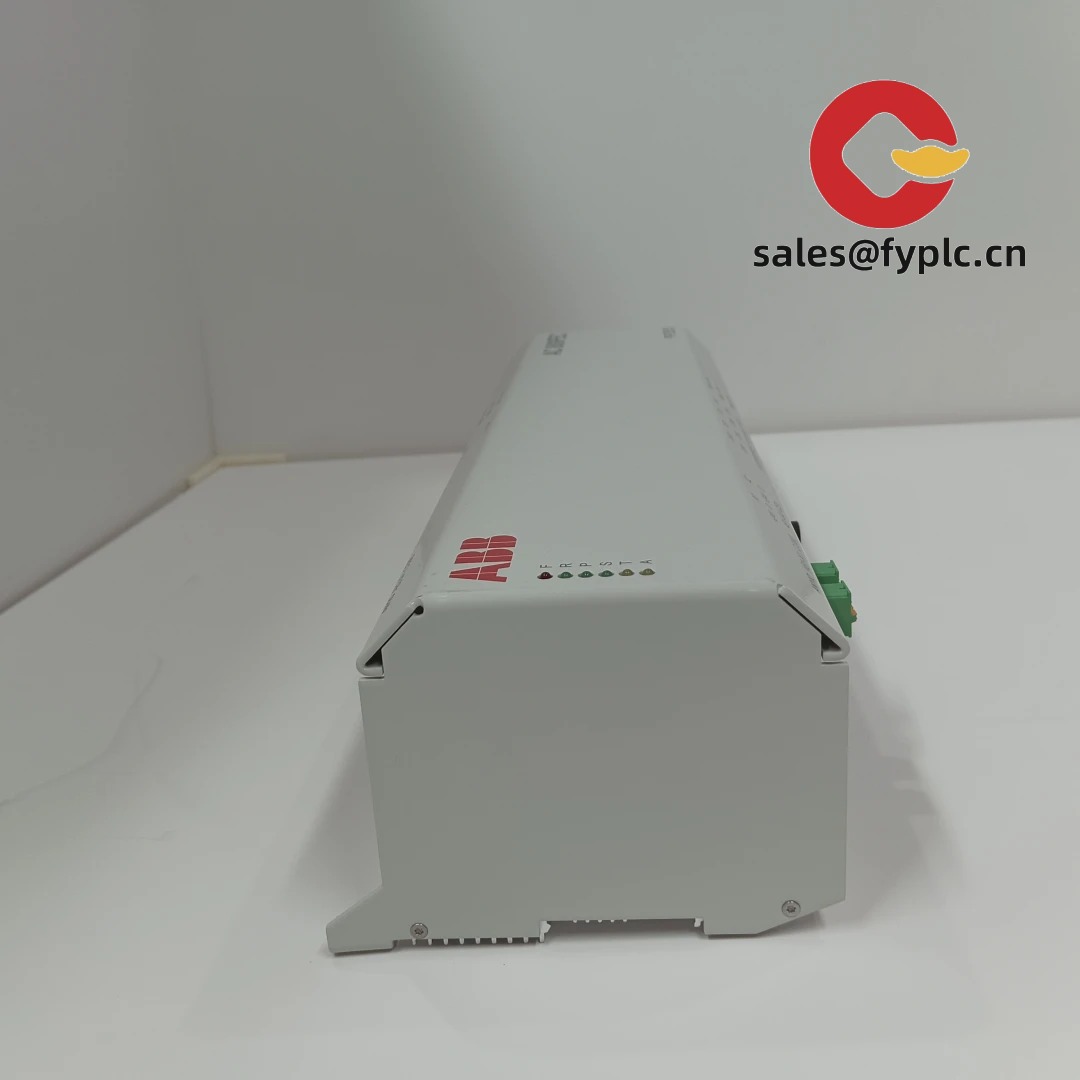

ABB AC800PEC Controller: Your Plant’s Reliable Process Nervous System

If you’ve ever wrestled with laggy controllers during critical batch processes, this ABB 3BHE039724R0C3D PPD513 A0C-100440 AC800PEC might feel like finding a spare key mid-emergency. From my experience troubleshooting refinery control rooms, this particular flavor of AC800PEC handles complex sequences without breaking a sweat—especially when your legacy PLCs start groaning under new safety protocols.

Why Engineers Keep This in Their Back Pocket

- Dual-core processing – Runs control logic and comms simultaneously. One plant manager told me it cut their distillation column response time by 40% during ammonia synthesis.

- Integrated safety controller – No separate SIL3 module needed for burner management. Typically shaves $8k off cabinet space and wiring.

- Redundant 24VDC power – Keeps running through brownouts. Saw this save a wastewater plant during last summer’s grid instability.

- Pre-loaded with ABB’s Process Library – Boiler control templates ready Day 1. Avoids those “why reinvent the PID loop?” headaches.

Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | ABB AC800PEC PPD513 (3BHE039724R0C3D) |

| HS Code | 8537.10.90 (Programmable controllers) |

| Power | 24VDC ±15%, 3.5A max (redundant inputs) |

| Dimensions | 120 x 180 x 140mm, 1.2kg |

| Operating Temp | -25°C to +60°C (derate above 50°C) |

| I/O & Comms | Profibus DP, Modbus TCP, 16-channel digital I/O (expandable) |

Where It Actually Shines

One thing I appreciate is how often this pops up in tricky retrofit scenarios. Think chemical reactors needing precise exothermic reaction control, or pulp mills where steam pressure spikes can wreck a shift. A paper mill in Wisconsin recently used it to replace aging Siemens S7-300s—they kept their old I/O racks but gained predictive maintenance alerts. In most cases, it’s the go-to when you need safety and process control in one box without certifying two separate systems.

Procurement Perks You Won’t Find in Brochures

- Cut engineering hours by reusing ABB’s pre-validated function blocks (we’ve seen 30% faster commissioning)

- 365-day warranty covers firmware glitches—unusual for industrial controllers where “it’s probably your code” is the default reply

- Budget-friendly 50% upfront payment. One client ordered three units during a furnace outage and had them running in 8 days via DHL Express.

Installation Reality Tips

Mount it in standard 19″ cabinets (IP20 rating), but keep it 100mm clear of VFDs—those harmonic noises love to crash controllers. You might notice the DIN rail clips feel flimsy until you lock them; just give ’em a firm twist. For maintenance: clean vents quarterly (dust bunnies love the heat sinks), and update firmware during planned shutdowns—never during production runs. Oh, and that redundant power? Test-switchover annually. I’ve seen plants skip this then panic when the backup fuse blew during a storm.

Certifications That Actually Matter

CE, UL 61010-1, ATEX Zone 2 (for cabinet-mounted use), and ISO 13849-1 PLd. The 365-day warranty covers parts and labor—no “consumables excluded” fine print. One caveat: calibration certificates cost extra, but most plants use ABB’s free FieldCare software to self-verify I/O accuracy.

Reviews

There are no reviews yet.