Description

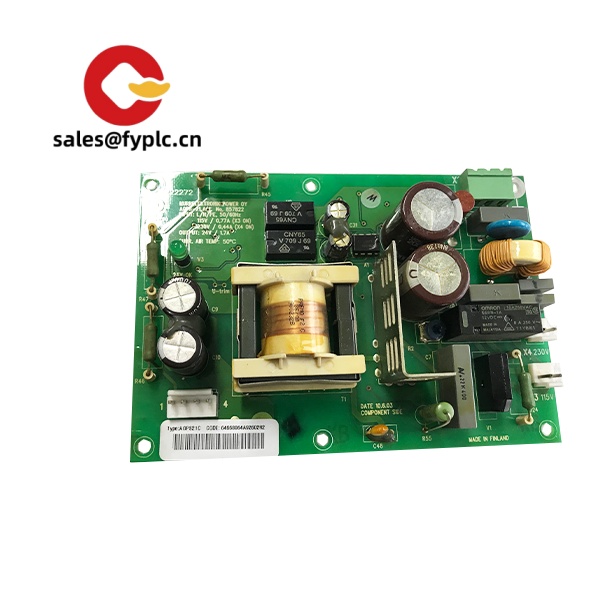

ABB AGPS-21C – General-Purpose Signal/Interface Module (Conformal Coated) for Industrial Automation

The ABB AGPS-21C is a compact, general-purpose module designed for integration inside ABB automation and protection systems where reliable signal interfacing and conditioning are needed. One thing I appreciate is the “C” suffix — in ABB’s portfolio that typically indicates a conformal-coated variant for harsher environments, which in many cases translates to better resilience against dust, humidity, and corrosive atmospheres. If you’re supporting a running plant and need a stable, like-for-like replacement or a spare to keep on the shelf, this unit fits that role well.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Conformal-coated design (C-variant): Helps resist moisture and airborne contaminants, typically extending service life in demanding cabinets.

- Stable signal interfacing: Designed for general-purpose integration inside ABB systems; from my experience, it’s commonly used where clean, reliable signal handling is a must.

- Backplane-powered module: Simplifies wiring by drawing power from the host device or base unit; you might notice reduced field wiring complexity.

- Compact footprint: Space-efficient plug-in format for dense control panels or relay racks.

- Service-friendly: Front-accessible connections and status indicators (on most builds) make troubleshooting faster during maintenance windows.

- Legacy system support: A practical choice for sustaining installed ABB platforms and avoiding disruptive redesigns.

Technical Specifications

| Brand / Model | ABB AGPS-21C |

| HS Code (reference) | 8538.90 (Parts for electrical control/automation equipment; final classification depends on local customs) |

| Power Requirements | Powered via host/backplane; nominal 24 V DC systems are typical in ABB panels (consumption commonly low, module-level). |

| Dimensions & Weight | Compact plug-in module format; panel footprint suited to dense racks. Typical module mass in the ~0.2–0.3 kg range. |

| Operating Temperature | 0 to +55 °C is common for coated ABB modules; storage typically -25 to +70 °C. |

| Signal Input/Output Types | General-purpose internal interfacing within ABB systems; no heavy field I/O expected. Used for conditioned signal handling and reliable internal connections. |

| Communication Interfaces | Backplane/host interface; external comms depend on the parent device. Check the specific host platform manual for port mapping. |

| Installation Method | Plug-in module for the designated ABB host slot or base; secured within a control cabinet/relay case per ABB guidelines. |

Application Fields

The AGPS-21C is typically used as part of ABB protection, control, or automation assemblies where clean, dependable internal signal handling is required. In practice we see it in:

- Power generation and substation control cabinets (supporting legacy ABB relay systems).

- Process automation lines in chemicals, pulp & paper, and food & beverage.

- Metals and mining plants where coated electronics perform better against dust and humidity.

- Marine and offshore skids that demand robust, coated modules inside protected enclosures.

A maintenance lead from a metals mill told us the coated version “seems to hold up better during summer humidity spikes,” which mirrors what we typically observe across coastal installations.

Advantages & Value

- Reliability in harsh cabinets: Conformal coating provides an extra margin against environmental stress.

- Compatibility with ABB host systems: Keeps your control architecture intact—no rushed redesigns or rewiring.

- Lifecycle support: Ideal as a like-for-like replacement or preventative spare to cut unplanned downtime.

- Procurement clarity: Defined lead times and a 365-day warranty help with planning and risk mitigation.

Installation & Maintenance

- Cabinet standards: Install in a clean, ventilated control cabinet; maintain ambient conditions within typical 0–55 °C.

- Handling: Observe ESD precautions; power down the host before insertion or removal.

- Wiring: Use shielded wiring where applicable; maintain proper grounding and segregation from high-voltage lines.

- Ventilation: Keep airflow paths unobstructed; avoid mounting near heat sources or frequency drives without separation.

- Routine checks: Inspect connectors, tighten terminals during scheduled shutdowns, and clean dust with dry, oil-free air.

- Firmware/config: If the host system uses configuration files, back them up before any module swap; restore and verify I/O mapping after replacement.

Quality & Certifications

- Manufactured under ABB’s quality systems (ISO 9001 across major facilities).

- CE compliant; RoHS alignment is typical for coated industrial modules.

- UL/CSA recognition may apply depending on host assembly; verify per project documentation.

- Warranty: 365 days (return-to-base).

Suggested Supporting Components

- Host base/backplane: The designated ABB base/slot for AGPS-21C in your specific system.

- Shielded control cable: For low-noise internal connections within the cabinet.

- Panel accessories: DIN-rail grounding kits and cable markers to keep maintenance fast and tidy.

From my experience, when you’re replacing an AGPS-21C in a live plant, the payoff is in avoiding surprises—confirm the host device firmware and any module-specific parameters before the swap. It saves a lot of back-and-forth during recommissioning.

Reviews

There are no reviews yet.