Description

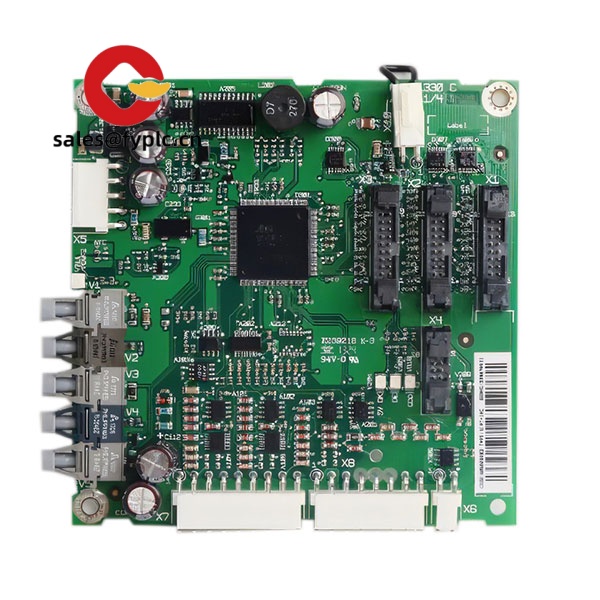

ABB AI950S (3KDE175521L9500) – Analog Input Module for Process Automation I/O

The ABB AI950S, part number 3KDE175521L9500, is an analog input module designed for ABB distributed control/PLC I/O stations in process industries. From my experience, it’s typically deployed where stable 4–20 mA and 0–10 V measurements matter—think flow, pressure, temperature transmitters, and similar field signals. You might notice that the “AI” lineage in ABB’s 900-series ecosystem points to straightforward integration with controller backplanes and proven EMC performance in noisy panels.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Analog signal acquisition – Suited for common process signals such as 4–20 mA and 0–10 V; ideal for transmitters and in-panel sensors.

- Backplane-powered design – Typically draws 24 VDC via the I/O base, keeping field wiring clean and service-friendly.

- Industrial EMC robustness – Designed for cabinet installation in plants where electrical noise is commonplace.

- Controller-friendly integration – Interfaces through the station backplane to ABB controllers used in process automation.

- DIN-rail installation – Plug-on terminal/base concept for quick module replacement and minimal downtime.

- Lifecycle serviceability – In many cases, modules can be swapped and auto-recognized by the controller configuration to speed recovery.

Technical Specifications

| Brand / Model | ABB AI950S (3KDE175521L9500) |

| HS Code | 853890 (Parts for electrical control apparatus) |

| Power Requirements | Typically 24 VDC provided via the I/O backplane (no separate field supply required for the module itself) |

| Signal Input Types | Analog inputs; commonly used for 4–20 mA and 0–10 V field signals; transmitter-powered loops typical |

| Communication Interfaces | Backplane bus to the I/O station/controller; plant network (e.g., PROFIBUS/PROFINET) handled by the I/O station interface module |

| Operating Temperature | 0 to +55 °C typical for cabinet-mounted ABB I/O modules |

| Installation Method | DIN-rail with base/terminal unit; front-access wiring; tool-less module replacement in most cases |

| Dimensions & Weight | Compact module form factor for multi-slot I/O bases; optimized for standard 600–800 mm depth cabinets |

Application Fields

Plants that standardize on ABB process automation platforms tend to use the AI950S for stable analog acquisition where uptime matters:

- Chemical and petrochemical units (flow, level, temperature transmitter loops)

- Water & wastewater treatment (filter differential pressure, dosing control)

- Power generation and utilities (boiler/aux systems, balance-of-plant)

- Metals, pulp & paper, food processing lines needing clean analog trends

A maintenance lead told us their swap time was “under 10 minutes from card-out to card-in, with the controller reading values immediately after a config check.” That’s common when modules share a drop-in footprint and backplane pinout.

Advantages & Value

- Reliability – Proven ABB I/O construction that typically holds calibration across temperature swings in standard cabinets.

- Compatibility – Designed for ABB controller ecosystems; minimizes engineering rework during replacements or expansions.

- Reduced downtime – Plug-and-play mechanics and backplane power simplify hot maintenance windows in many cases.

- Cost control – Drop-in module replacement usually avoids rewiring and panel changes, trimming labor and outage time.

- Technical support – We assist with selection, mapping, and commissioning notes to keep changeovers predictable.

Installation & Maintenance

- Cabinet standards – Mount on DIN rail in a dry, ventilated panel; follow spacing guidelines to aid heat dissipation.

- Wiring practices – Use shielded twisted-pair for analog loops; land shields at one end to minimize ground loops.

- Power & grounding – Clean 24 VDC backplane supply and a low-impedance ground bus help measurement stability.

- Commissioning – Verify channel type (current vs. voltage) and scaling in the controller. Perform loop checks for each transmitter.

- Routine maintenance – Periodic terminal re-torque and dust removal; review trending for sensor drift; firmware updates are controller-driven and not typically required for the I/O card itself.

- Safety – De-energize the I/O segment before removing the module unless your system explicitly supports hot-swap and procedures allow it.

Quality & Certifications

- Manufacturer quality systems: ISO 9001

- Typical product compliance: CE; RoHS; often cULus for North America (varies by exact production revision)

- Warranty: 365 days replacement/repair support

Reviews

There are no reviews yet.