Description

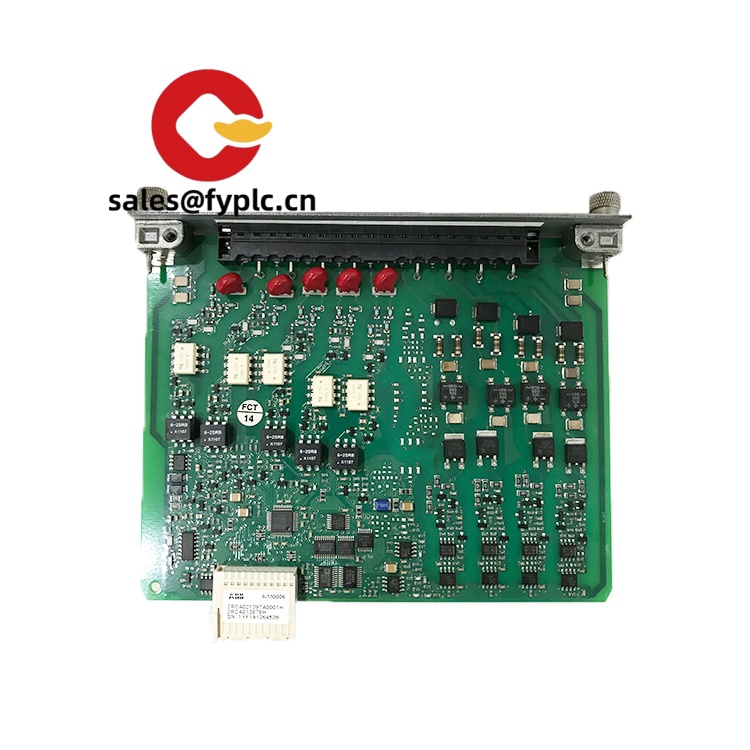

ABB AIM0006-2RCA021397A0001F – Six‑Channel Analog Input Module for Reliable PLC/DCS Expansion

The AIM0006-2RCA021397A0001F is a compact, six‑channel analog input module that typically drops into an industrial PLC/DCS rack to bring in clean, isolated measurements from the field. From my experience, users pick it when they need stable 4–20 mA or 0–10 V acquisition with minimal fuss—think flow, pressure, and temperature loops that should just work. You might notice that channel configuration is straightforward and diagnostics are clear, which in many cases shortens commissioning time and reduces nuisance trips during startup.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Six isolated analog inputs – Typically supports 4–20 mA and 0–10 V signals for process variables across utilities and production lines.

- Per‑channel configuration – Set each channel to current or voltage; in many cases, this avoids extra signal conditioning hardware.

- Industrial‑grade accuracy – Stable A/D conversion (often 16‑bit class) to capture slow‑changing process signals without drift headaches.

- Galvanic isolation – Channel‑to‑bus and channel‑to‑channel isolation helps mitigate ground loops and electrical noise.

- Diagnostics and status LEDs – Quick fault localization for open loop, over‑range, or wiring errors, which typically cuts troubleshooting time.

- Compact DIN‑rail/rack footprint – Saves panel space and keeps cabinet layouts clean with standard terminal wiring practices.

Technical Specifications

| Brand / Model | ABB AIM0006-2RCA021397A0001F |

| HS Code | 853890 (Parts for electrical control apparatus) |

| Power Requirements | 24 VDC nominal (typically 20–30 VDC), module consumption < 3 W |

| Signal Input/Output Types | 6x AI channels; 4–20 mA (active/passive loop) and 0–10 V; configurable per channel; isolation provided |

| Resolution & Sampling | Typically 16‑bit A/D; sampling suitable for process signals (100–250 ms/ch typical) |

| Communication Interfaces | Backplane/rack bus interface to PLC/DCS; service status via front LEDs |

| Installation Method | DIN‑rail or rack carrier, screw/spring‑cage terminal wiring |

| Dimensions & Weight | Approx. 120 × 100 × 25 mm; ~0.2 kg (typical for this class) |

| Operating Temperature | 0 to +55 °C (industrial cabinet environment) |

| Wiring | Shielded twisted pairs recommended; typical 0.5–2.5 mm² conductors |

Application Fields

This module fits well in process and discrete manufacturing where reliable analog acquisition matters:

- Water and wastewater – Level, flow, turbidity 4–20 mA loops

- Food & beverage – Temperature and pressure on CIP/SIP skids

- Chemicals & pharma – Dosing, reactor jackets, utility headers

- Power & utilities – Boiler feedwater, lube oil systems, balance‑of‑plant

- OEM machinery – Compact panels where space and clean wiring are priorities

Advantages & Value

- Reliability – Stable readings and robust isolation help avoid drift and noise issues in tough cabinets.

- Compatibility – Designed to sit on a standard industrial backplane; typically integrates smoothly with existing ABB racks and engineering tools.

- Cost control – Universal inputs reduce the need for separate signal conditioners, saving both space and budget.

- Lifecycle support – Clear status LEDs and simple diagnostics ease maintenance, which tends to lower downtime costs.

Installation & Maintenance

A clean cabinet makes a big difference. Keep the module on a DIN rail or rack with good ventilation; I typically leave at least 25 mm clearance above and below for airflow. Use shielded twisted‑pair cable for analog signals and ground shields at a single point to reduce hum. Separate low‑level analog wiring from power and relay lines.

- Power: 24 VDC with proper overcurrent protection; follow polarity labels on the base.

- Wiring: 0.5–2.5 mm² conductors; tighten terminals to the recommended torque to prevent intermittents.

- Safety: De‑energize the cabinet before insertion/removal; allow a short discharge period to protect electronics.

- Routine maintenance: Quarterly visual check, connector re‑seat if needed, dust removal with dry air, and periodic loop verification/calibration.

- Firmware/config: Back up configuration before updates; confirm module revision compatibility in your engineering toolset.

A maintenance lead at a beverage plant told us their switch from mixed signal conditioners to a universal AI like this cut their commissioning time by “at least a day per line”—mainly due to simpler wiring and fewer SKUs on the shelf.

Quality & Certifications

- Compliance: CE and RoHS (typical for this series); UL listing is commonly available for control panels

- Manufacturer’s warranty: 12 months (365 days)

Reviews

There are no reviews yet.