Description

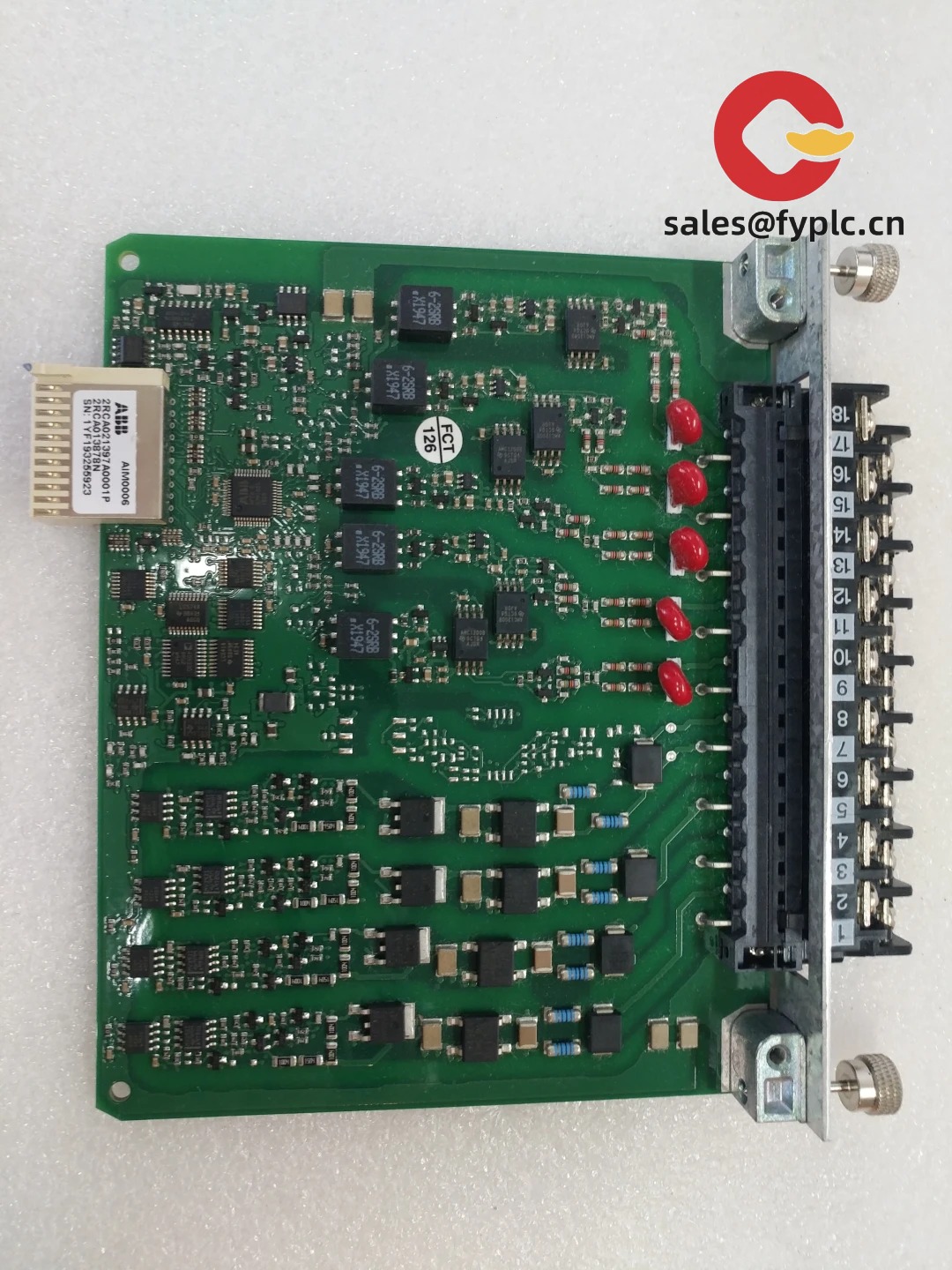

ABB AIM0006 (2RCA021397A0001P) – 6‑Channel Analog Input Module for reliable process signal acquisition

From my experience with ABB control hardware, the AIM0006 designation typically refers to a 6‑channel analog input module designed to capture common process signals like 4–20 mA and 0–10 V. The variant code 2RCA021397A0001P points to a specific build or revision, often used for exact spare-part matching. If you’re standardizing on ABB controllers, this module seems to fit neatly into the system backplane and keeps wiring practical for cabinet installations.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment method: 50% advance payment; full payment prior to delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Six analog input channels – Ideal for compact skids or cells where you need multiple process points without expanding the rack.

- Supports common industrial ranges – Typically compatible with 4–20 mA and 0–10 V inputs for pressure, flow, level, and temperature transmitters.

- Backplane integration – Seamless fit in ABB controller ecosystems; you might notice faster commissioning when the whole stack is ABB.

- Status LEDs and basic diagnostics – Quick channel health checks reduce troubleshooting time on the plant floor.

- Shielding and filtering design – In many cases, helps mitigate electrical noise from VFDs and contactors in mixed cabinets.

Technical Specifications

| Brand / Model | ABB AIM0006, Part No. 2RCA021397A0001P |

| HS Code | 8538.90 (Parts suitable for use with apparatus of 8535/8536/8537) |

| Power Requirements | 24 VDC supplied via system backplane; typical consumption < 5 W |

| Dimensions & Weight | Compact plug‑in module form factor; typical module weight around 0.2–0.3 kg |

| Operating Temperature | 0 to +55 °C (control cabinet environment; non‑condensing) |

| Signal Input/Output Types | 6 analog inputs; supports common 4–20 mA and 0–10 V ranges (single‑ended), typical 12–16 bit conversion |

| Communication Interfaces | System backplane bus connection to ABB controller; no front Ethernet/serial ports |

| Installation Method | Rack/DIN‑rail within a protected cabinet; mates to terminal base/backplane for field wiring |

Note: Channel ranges and resolution can vary by firmware or sub‑revision. If you need an exact match to an installed base, we can cross‑verify the 2RCA021397A0001P code against your controller revision before shipping.

Application Fields

- Process skids and utilities – steam, air, water, and gas loops with 4–20 mA transmitters.

- Manufacturing cells and robotics – analog feedback from force/torque sensors, tension control, or valve positioners.

- Water and wastewater – level, pressure, and flow monitoring in compact control panels.

- Machine tools and material handling – 0–10 V drives and actuator feedback into ABB controllers.

A maintenance lead at a packaging plant told me they swapped in an AIM0006 on an existing rack and noticed cleaner readings near VFDs after tightening shielding and grounding—small changes, but it saved them hours of chasing noise.

Advantages & Value

- Reliability – Proven ABB backplane integration, with stable signal conditioning in most cabinet environments.

- Compatibility – Works within ABB controller ecosystems, reducing engineering time and spare‑parts complexity.

- Cost control – Six channels per slot is a sweet spot for compact systems; fewer modules, fewer terminal bases.

- Technical support – We can help validate ranges, wiring bases, and replacement compatibility by serial/part code.

Installation & Maintenance

- Cabinet and mounting – Install in a clean, ventilated control cabinet; follow DIN‑rail/rack guidelines and leave space for airflow.

- Wiring – Use shielded twisted pair for analog lines; ground shields at one end only. Keep analog wiring away from VFD and relay bundles.

- Power and loops – For 4–20 mA loops, confirm loop power and burden; check transmitter polarity and any shunt resistors if reading in voltage.

- Safety – De‑energize before inserting/removing modules. Verify cabinet earth bonding and overcurrent protection.

- Routine checks – Periodic input scaling verification and point‑to‑point loop tests; clean connectors, and keep firmware/parameter sets aligned with the controller.

Quality & Certifications

- Typical compliance: CE marking; RoHS. Many ABB I/O modules are UL recognized for control panels.

- Manufacturer’s warranty practices usually apply; we provide a 365‑day warranty on supply.

If you can share your controller type and current module list, I can double‑check that AIM0006 (2RCA021397A0001P) aligns with your backplane and terminal base, and confirm the exact input ranges you plan to use.

Reviews

There are no reviews yet.