Description

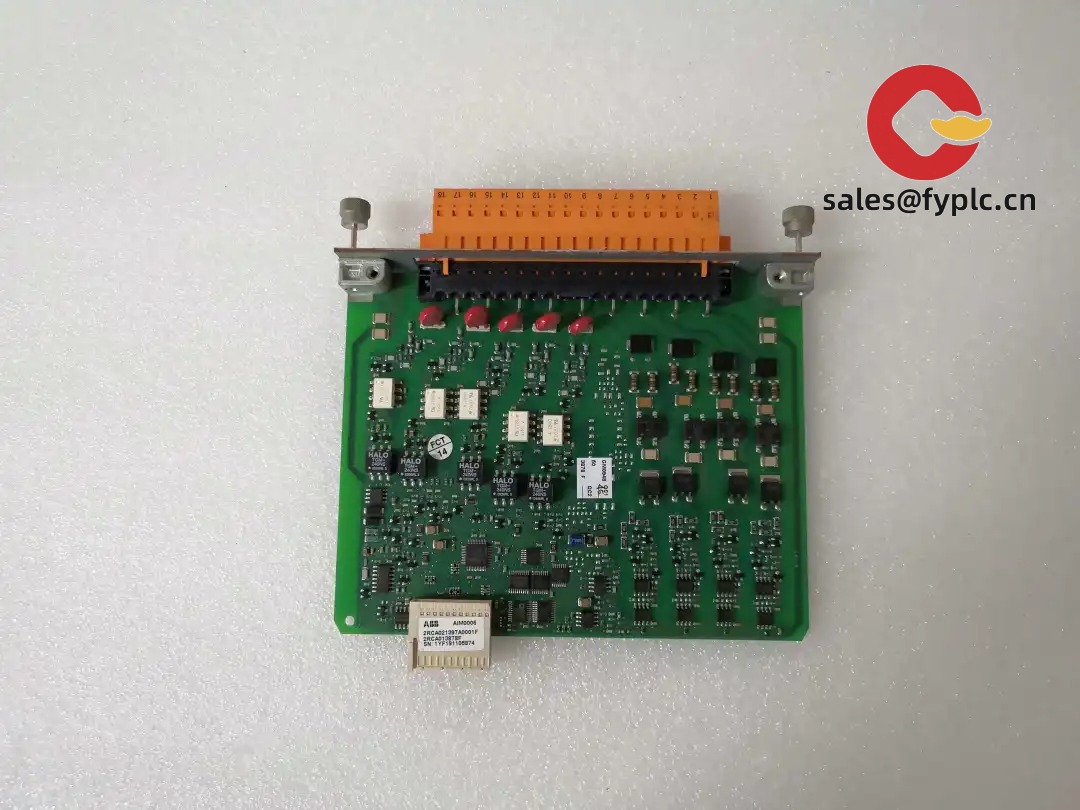

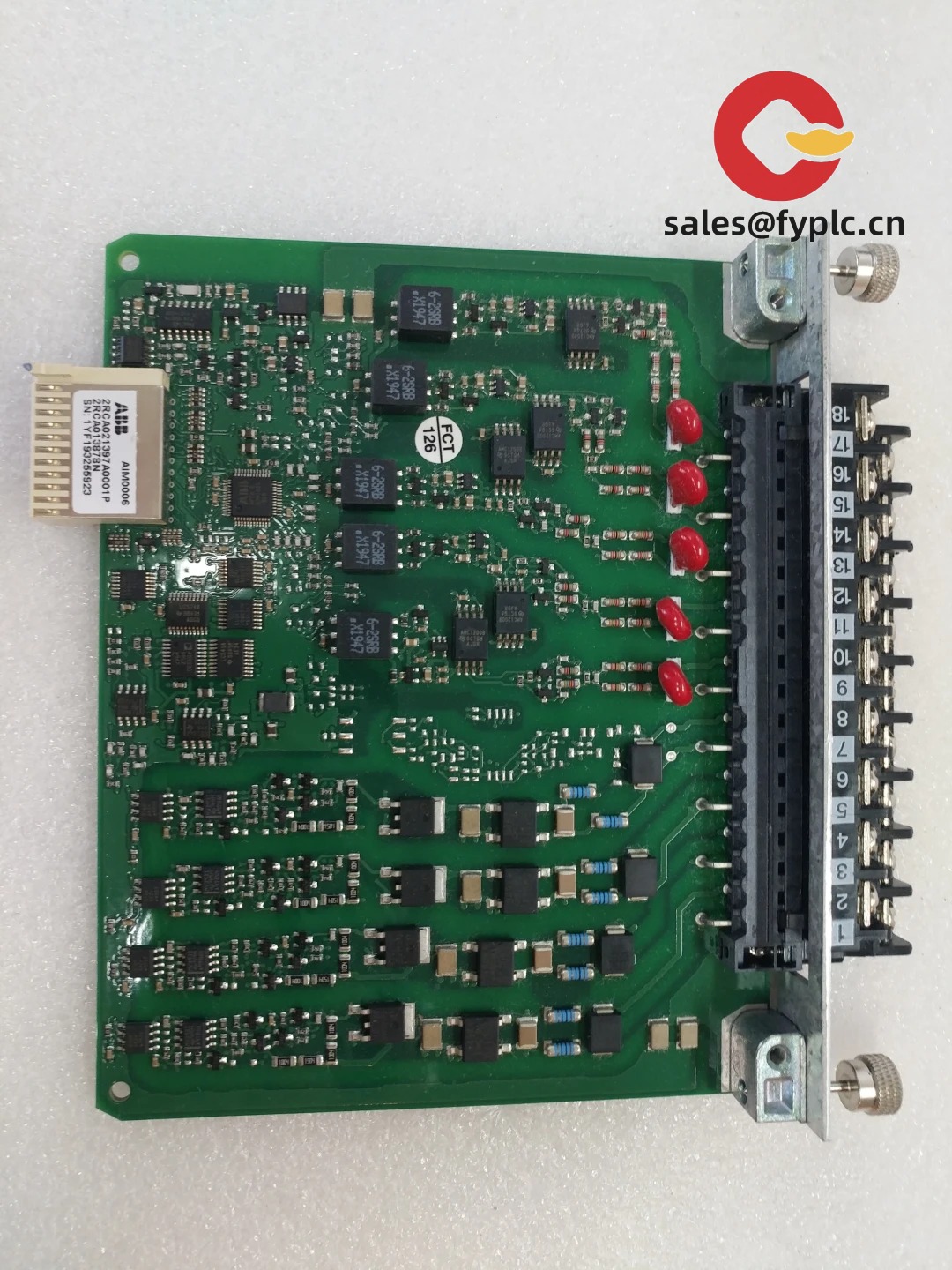

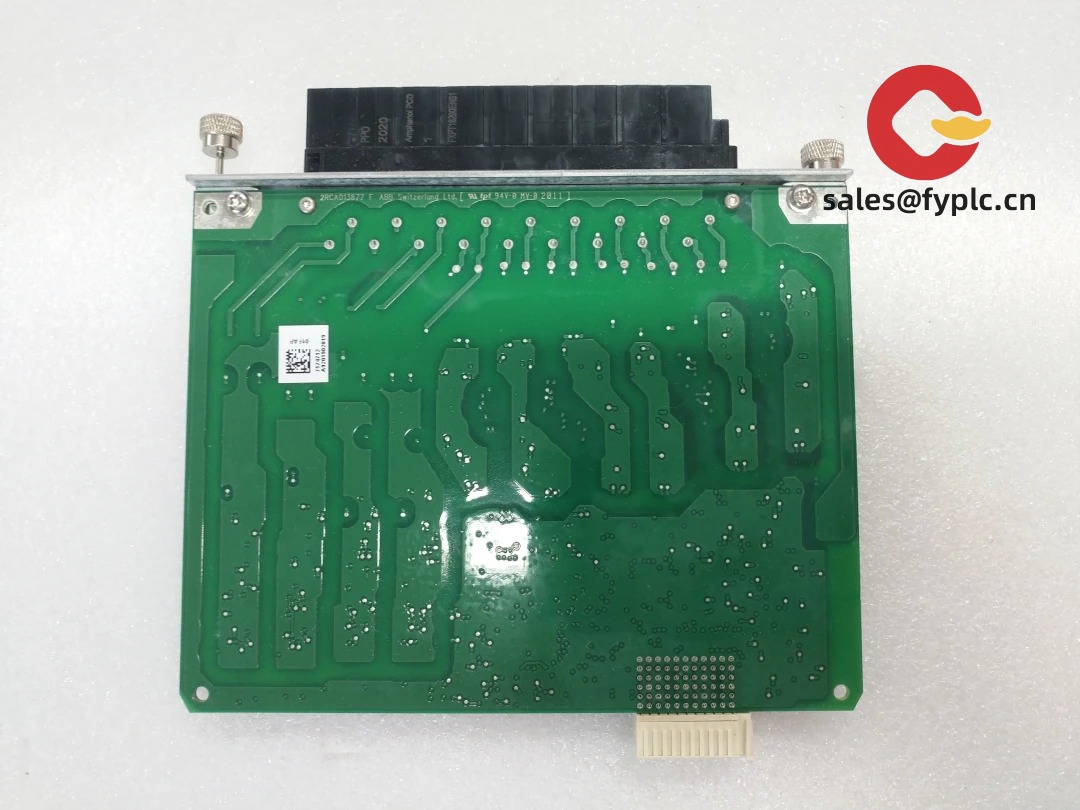

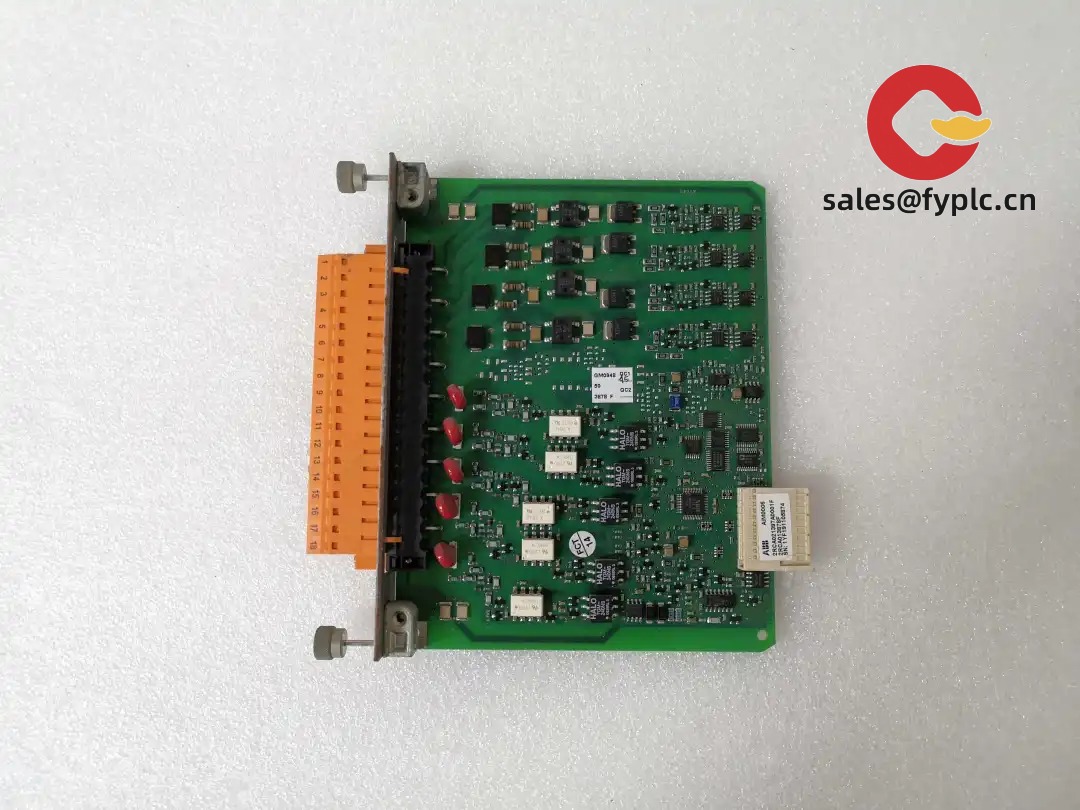

ABB AIM0016 — Analog Input Module for Compact AC500 PLC Systems

The ABB AIM0016 is a 16-channel analog input module designed specifically for the AC500 family of programmable logic controllers. It’s one of those components you don’t think about until your system needs precise, noise-resistant measurement of temperature, pressure, or flow signals — and then it becomes indispensable. From my experience supporting OEMs in water treatment and packaging lines, this module consistently handles field wiring chaos better than most peers in its class.

Key Features

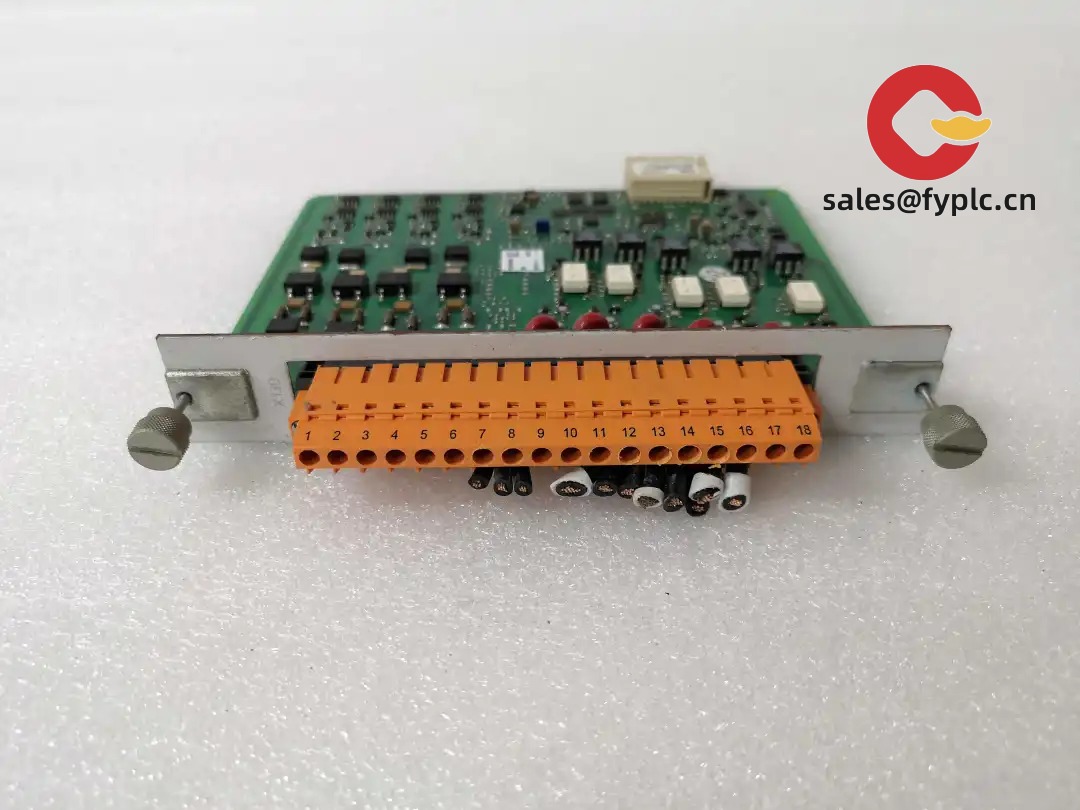

- 16 universal analog inputs: Configurable per channel for voltage (±10 V, 0–10 V) or current (0/4–20 mA) — no hardware jumpers needed. One thing I appreciate is how easily engineers reassign inputs during commissioning without swapping modules.

- Galvanic isolation: 500 VAC between field circuits and the backplane. In many cases, this eliminates ground-loop headaches when integrating third-party sensors.

- 16-bit resolution with 0.1% typical accuracy: Not lab-grade, but more than enough for process monitoring where repeatability matters more than absolute metrology.

- Integrated diagnostics: LED indicators per channel (OK, overrange, open-circuit), plus firmware-accessible status bits. A food processing client once told us this cut their troubleshooting time by ~40% during seasonal sensor drift events.

- Direct AC500 mounting: Slides onto the standard AC500 baseplate — no separate power supply or terminal blocks required. You might notice that cabinet space savings add up quickly in dense I/O cabinets.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB AIM0016 |

| HS Code | 8537.10.90 (Industrial programmable controllers & parts) |

| Power Requirements | Supplied via AC500 backplane (24 V DC ±15%, max. 150 mA) |

| Dimensions (W × H × D) | 30 mm × 125 mm × 125 mm (standard AC500 width) |

| Weight | Approx. 210 g |

| Operating Temperature | -25 °C to +60 °C (derating above 55 °C) |

| Signal Input Types | Voltage: ±10 V, 0–10 V; Current: 0/4–20 mA (all channels configurable) |

| Resolution / Accuracy | 16-bit; ±0.1% of full scale (typical at 25 °C) |

| Communication Interface | Integrated into AC500 bus (no external comms — data exchanged via backplane) |

| Installation Method | DIN rail mount (with AC500 baseplate); tool-less locking |

Application Fields

You’ll commonly find the AIM0016 deployed in environments where analog signal integrity and compact I/O density matter — think HVAC control panels in commercial buildings, dosing systems in municipal wastewater plants, or temperature profiling on pharmaceutical batch ovens. It’s less suited for high-speed motion control (where you’d lean toward dedicated high-speed counters), but shines where reliability trumps microsecond timing. A recent customer in dairy processing used it to consolidate 12 RTD inputs from a pasteurization loop into a single slot — cutting wiring labor and reducing potential failure points.

Advantages & Value

- Lower total cost of ownership: No need for external signal conditioners or isolated barriers in most standard installations — the built-in isolation and configurable ranges simplify BOMs.

- AC500 ecosystem compatibility: Firmware updates, configuration, and diagnostics flow seamlessly through Automation Builder — no proprietary software licenses or dongles required.

- Supply chain predictability: ABB maintains steady production of this module, and it’s rarely subject to long lead times — unlike some niche analog modules that vanish for months.

- Support continuity: Even though ABB has streamlined its AC500 documentation, core engineering support remains active — especially for modules like the AIM0016 that are still widely installed in legacy and hybrid systems.

Installation & Maintenance

Mount only in clean, dry cabinets meeting IP54 minimum (though IP65 is recommended if ambient dust or moisture is present). Ensure ≥50 mm clearance above/below for convection cooling — we’ve seen thermal derating kick in earlier than expected when stacked tightly beside power supplies. Use twisted-pair shielded cable for all analog runs, and terminate shields at the module end only (not both ends) to avoid ground loops. Routine maintenance is minimal: visually inspect connectors every 6 months, verify calibration annually (or after any physical impact), and update firmware when new AC500 library versions are released — typically every 12–18 months. Avoid using compressed air directly on the PCB; static discharge can disturb internal references.

Quality & Certifications

Certified to CE (EN 61000-6-2/-6-4), UL 61010-1 (industrial control equipment), RoHS 2011/65/EU, and meets IEC 61131-2 immunity requirements. ABB provides a standard 365-day warranty covering material and workmanship defects. Units are factory-tested for channel linearity, isolation voltage, and thermal stability before shipment — and batch traceability is maintained for 5 years.

Our Order Placement Process and Guarantees

- Warranty period: 365 days from date of delivery

- Delivery time: Typically 1 week for in-stock units; maximum 4 weeks if requiring factory allocation

- Payment terms: 50% advance payment, balance prior to shipment

- Shipping: Fedex, UPS, or DHL express — fully trackable, with insurance included

Reviews

There are no reviews yet.