Description

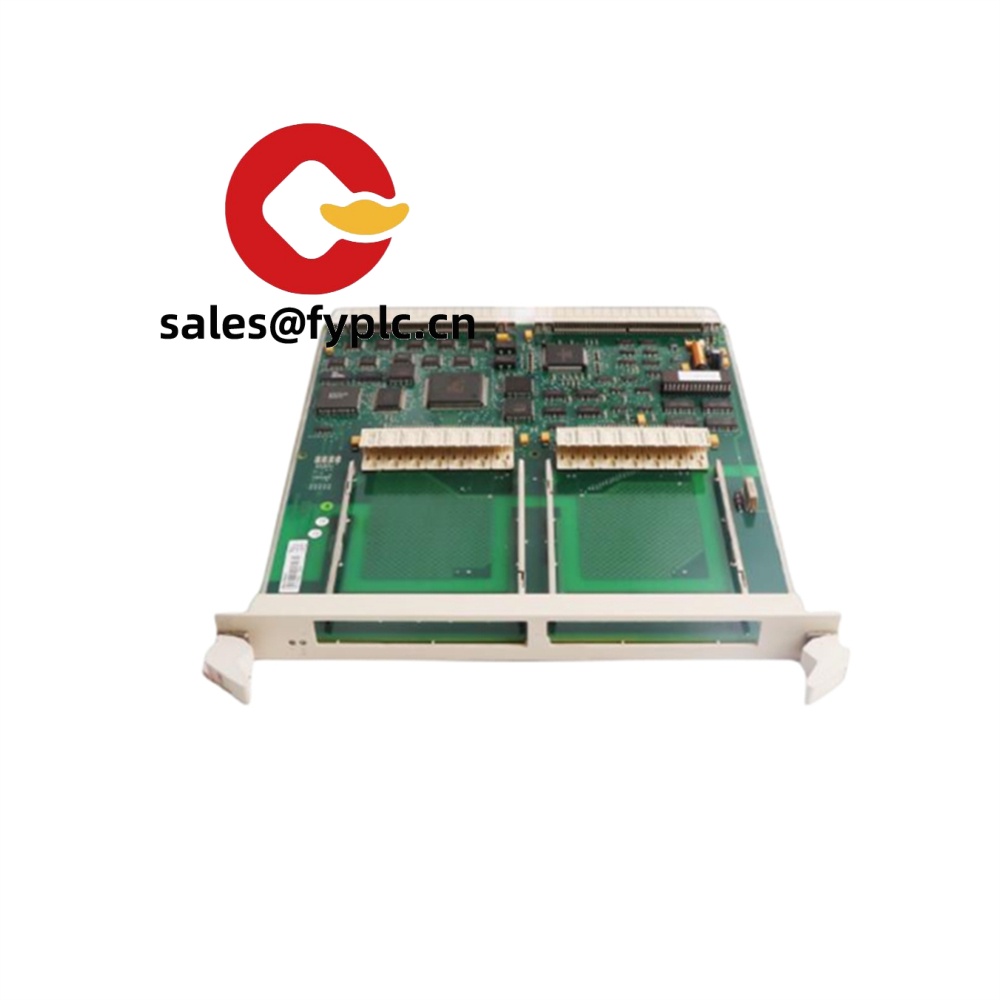

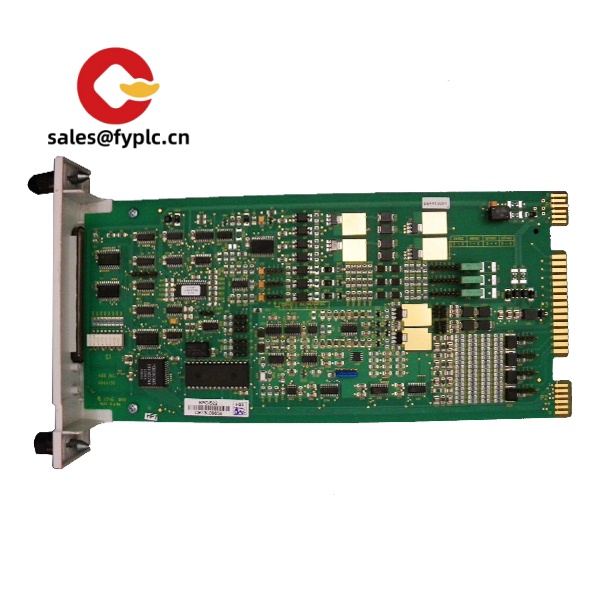

ABB ARCOL 0339 – High-Reliability Redundancy Controller for Industrial Automation Systems

If you’re managing mission-critical process automation—especially in power generation, oil & gas, or large-scale manufacturing—the ABB ARCOL 0339 isn’t just another controller. It’s the backbone of ABB’s Symphony® Plus (S+), designed to maintain system integrity even under failure conditions. From my experience, one thing I appreciate is how seamlessly it handles redundancy switching without disrupting control loops. You might notice that unlike standard PLCs, this module doesn’t just fail over—it anticipates issues and prepares the standby unit in real time.

Key Features

- Dual-redundant architecture: Ensures zero downtime during controller faults or maintenance. Typically switches within milliseconds—fast enough that most processes won’t register a hiccup.

- Built for Symphony® Plus: Integrates natively with ABB’s S+ ecosystem. In many cases, this reduces engineering time by avoiding protocol translation layers.

- Fiber-optic synchronization link: Uses dedicated fiber between primary and backup units to eliminate network congestion risks on Ethernet.

- Hot-swappable: Can be replaced or serviced without powering down the rack. One customer mentioned they did a full replacement during peak load without tripping a single alarm.

- Integrated diagnostics: Real-time health monitoring via Control Builder S+ software. Alerts appear well before hard failures occur.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand / Model | ABB ARCOL 0339 |

| HS Code | 8537.10.90 (Programmable controllers, industrial) |

| Power Requirements | 24 VDC nominal (range: 19.2–30 VDC); typically draws ~2.5 A per unit |

| Dimensions & Weight | Approx. 320 mm H × 45 mm W × 280 mm D; ~1.8 kg |

| Operating Temperature | 0°C to +55°C (with derating above 45°C) |

| Signal I/O Types | N/A (controller-level device; interfaces with I/O modules via Profibus DP or Modbus) |

| Communication Interfaces | Dual redundant Ethernet (10/100 Mbps), fiber-optic sync port, RS-485 for fieldbus |

| Installation Method | DIN-rail mounted in ABB S+ cabinet (typically used in pairs for redundancy) |

Application Fields

The ARCOL 0339 shines in environments where unplanned outages carry high costs. It’s commonly found in thermal and hydroelectric power plants managing turbine control, refineries handling burner management systems, and chemical facilities running continuous batch processes. Some wastewater treatment plants also use it for SCADA-level coordination when interfacing with legacy analog systems. It appears that its strongest value is not raw speed but deterministic behavior under stress—something engineers tend to appreciate more after commissioning than during selection.

Advantages & Value

Procurement teams often look at upfront cost first, but with ARCOL 0339, the long-term ROI tells a better story. Because it’s part of ABB’s long-supported S+ platform, spare parts availability remains strong—even for older revisions. Compatibility with existing S+ engineering tools means less training overhead. And since it supports hot swapping and predictive diagnostics, maintenance scheduling becomes far more flexible. In practice, one plant reduced forced outages related to controller faults by about 70% after upgrading from an older non-redundant setup.

Installation & Maintenance

Install in a clean, well-ventilated control cabinet meeting IP54 standards. Make sure DIN rails are securely fastened and grounding is continuous across all modules. Keep fiber-optic sync cables away from high-voltage wiring—EMI can degrade signal integrity over time. For safety, always disable power to adjacent slots before inserting or removing the module, even though it’s rated for hot-swap. On the maintenance side, routine firmware updates (every 12–18 months) help avoid compatibility drift. Calibration isn’t needed for the controller itself, but periodic checks on connected I/O modules are recommended. Cleaning dust buildup every six months helps prevent overheating, especially in industrial environments with airborne particulates.

Quality & Certifications

The ARCOL 0339 carries CE, UL, and CSA certifications, confirming compliance with international industrial safety and EMC standards. It’s also RoHS-compliant, meaning no restricted hazardous substances were used in production. ABB typically backs these units with a 3-year warranty against manufacturing defects—though we extend the same guarantee regardless of original manufacture date, as long as the unit hasn’t been modified or improperly installed.

Order Placement & Guarantees

We keep several ARCOL 0339 units in stock—delivery usually takes about one week. If not available immediately, lead time won’t exceed four weeks. Payment is 50% upfront, with the balance due before shipment. We ship via FedEx, UPS, or DHL depending on destination and urgency. All units are tested prior to dispatch and covered by a 365-day warranty from the date of delivery.

Reviews

There are no reviews yet.