Description

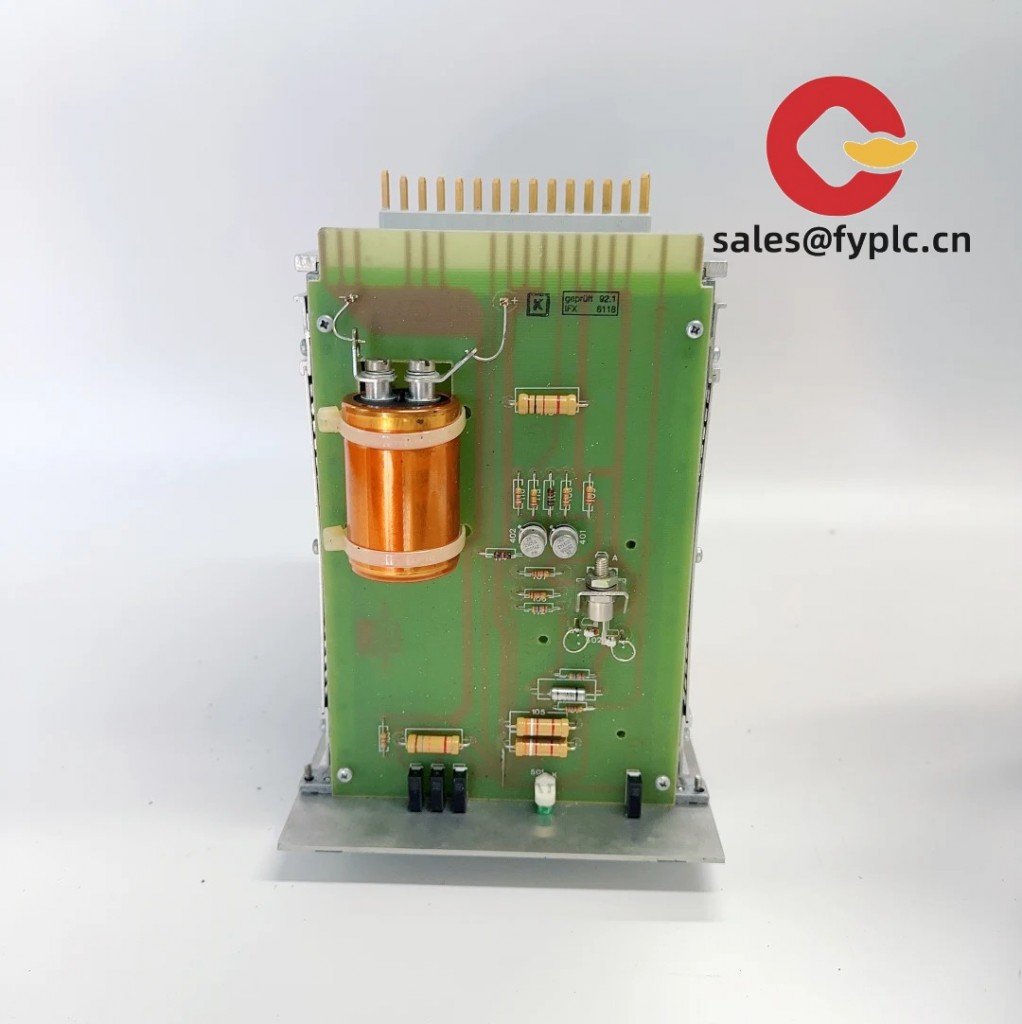

ABB B3EA (HENF315147R1) Control Board – OEM plug-in PCB for ABB drive and controller platforms

The ABB B3EA identified by the PCB code HENF315147R1 is an OEM control board used inside ABB industrial drive and automation systems. It’s a direct-fit replacement board intended for field service and lifecycle support—so maintenance teams can restore a downed cabinet quickly without redesign or re-qualification. From my experience, this part shows up in several ABB low-voltage drive and controller families where it interfaces with the system backplane and internal I/O.

You might notice that third-party substitutes are rare for this type of assembly. Keeping an original ABB B3EA on the shelf typically reduces downtime risk, especially in plants running continuous processes. A maintenance lead from a metals line told us they swapped this board in under 15 minutes and were trending stable again before the end of shift.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: In-stock ships in ~1 week; not in stock typically under 1 month

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Condition & testing: Genuine ABB OEM part; functional test and ESD-safe packaging

Key Features

- Direct replacement for ABB systems: B3EA board designated by part code HENF315147R1 for like‑for‑like swap with existing hardware.

- Backplane integration: Interfaces to the host drive/controller via ABB’s internal edge/backplane connector; no external wiring changes.

- OEM firmware/compatibility: Works with the host platform’s existing configuration in most cases—minimizing commissioning time.

- Service-friendly: Plug-in format supports fast replacement during scheduled maintenance or fault recovery.

- Traceability: Full part-number traceability for revision control and audit documentation.

- Protected packaging: Shipped in ESD-safe materials to reduce handling risk at the job site.

Technical Specifications

| Brand / Model | ABB B3EA (HENF315147R1) |

| HS Code | 8538.90 (Parts for electrical control/switchgear apparatus) |

| Power Requirements | Powered by host backplane (no separate external supply required) |

| Operating Temperature | Follows host device rating; typically 0 to 55 °C in a ventilated control cabinet |

| Signal I/O Types | Internal logic and conditioned signals via system backplane; no user-facing terminals on the board |

| Communication Interfaces | Proprietary ABB internal bus via edge/backplane connector |

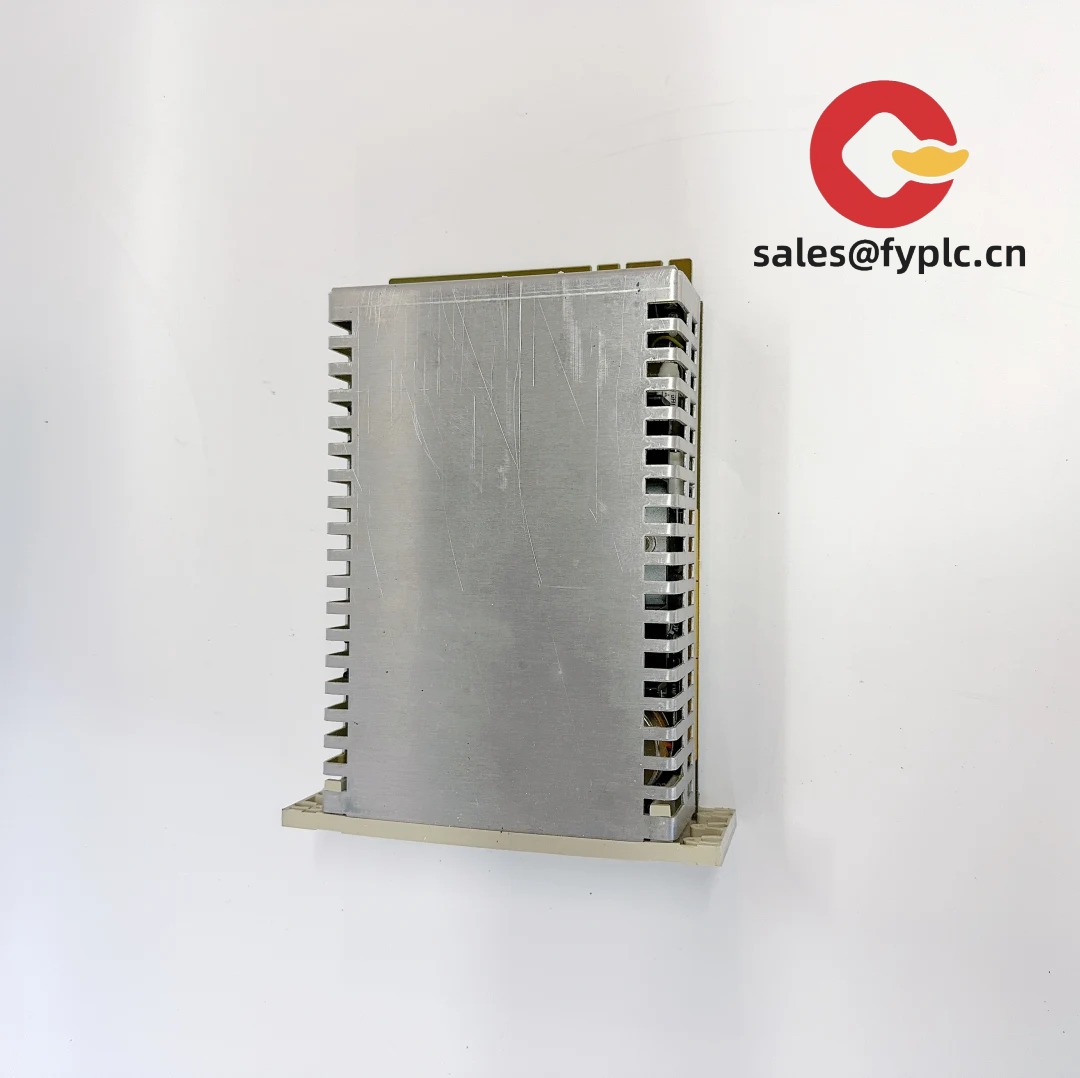

| Installation Method | Plug-in PCB; insert into designated slot with ESD precautions and secure per host hardware guide |

| Dimensions & Weight | PCB-level assembly; shipping weight approx. 0.30 kg |

Application Fields

This board is typically used inside ABB low-voltage drives and controller cabinets across continuous and batch processes. Common environments include:

- Metals and mining lines (rolling, conveying, hoists)

- Pulp & paper (winders, coaters, section drives)

- Power generation balance-of-plant systems

- Oil & gas and chemicals (pumps, compressors, mixers)

- Water & wastewater (blowers, high-efficiency pumping)

- Marine and port equipment where ABB drives are specified

Advantages & Value

- Reliability: OEM hardware preserves the original MTBF profile and avoids integration surprises.

- Compatibility: Drop-in fit with matching revisions means fewer parameter changes and shorter downtime.

- Cost control: A quick board swap can prevent extended production loss—often the biggest cost driver.

- Supportability: Traceable part number (HENF315147R1) simplifies technical support and lifecycle planning.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated enclosure to the host’s specification; keep clear airflow around the drive/controller.

- ESD safety: Wear an antistatic wrist strap; handle by edges; keep in ESD packaging until installation.

- Wiring: No external wiring to the board itself; ensure backplane connectors are clean and fully seated.

- Commissioning: Follow the host device procedure. In many cases, no parameter changes are required for a like‑for‑like replacement.

- Routine care: Periodically remove cabinet dust with dry, oil‑free air; inspect connectors for oxidation; keep firmware of the host system current as recommended by ABB.

- Spares practice: Plants typically hold 1–2 boards per critical line to cover both failure and revision alignment.

Quality & Certifications

- Manufactured to ABB quality standards; supplied as a genuine OEM spare

- CE and RoHS conformity applies at the host system level; this board is a component

- Typically used in UL/CE certified assemblies when installed per the original design

- 365‑day warranty coverage from date of shipment

Related Supporting Components (commonly paired)

Depending on the cabinet configuration, users often procure related items together to minimize downtime:

- Backplane/rack hardware for the target ABB drive/controller

- Edge connector kits or retention hardware specific to the slot

- Cooling fans and air filters for the hosting drive to maintain thermal margins

- ESD-safe service kits for on-site handling and storage

If you need a quick compatibility check against your drive/controller typeplate, share the cabinet model and current board revision—we’ll verify fitment and lead time before you commit.

Reviews

There are no reviews yet.