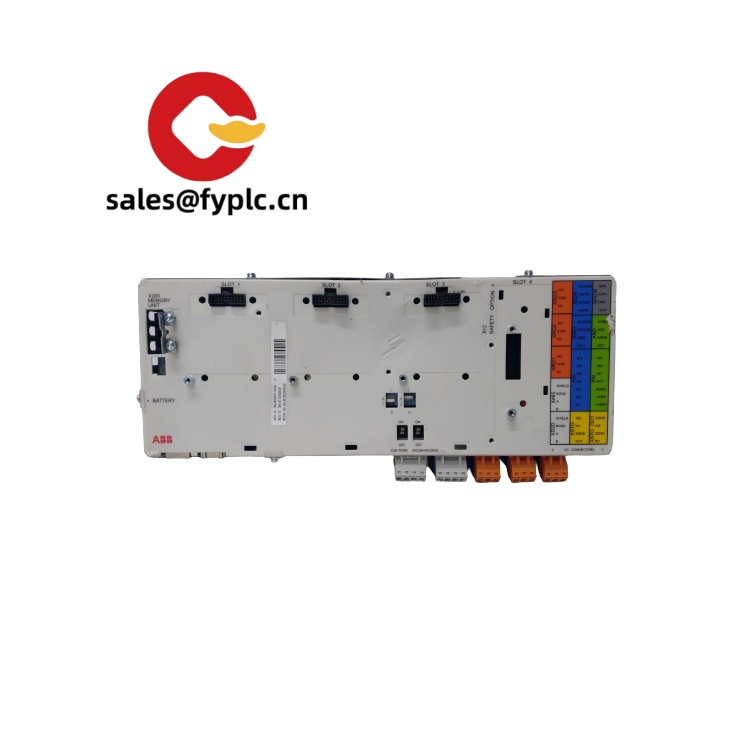

Description

ABB BCU-12 — Compact Bus Coupler Unit for Modular AC500 PLC Systems

Let’s cut to the chase: the ABB BCU-12 isn’t flashy—but it’s the kind of component that quietly keeps your AC500-based control architecture humming. I’ve seen it deployed in everything from regional water treatment skids to packaging lines where bus integrity and deterministic response matter more than glossy specs. It’s a passive coupler, yes—but don’t mistake “passive” for “basic.” This unit handles voltage isolation, signal buffering, and bus segmentation with minimal fuss and zero configuration.

Key Features

- Galvanic isolation (500 VAC) — Prevents ground loops and noise propagation between bus segments, especially useful when integrating third-party I/O or field devices on extended cabinets.

- Automatic bus termination detection — No dip switches or manual jumpers. It senses whether it’s at the end of the bus and enables/disables termination resistors accordingly—fewer wiring errors during commissioning.

- Hot-swap capable (with compatible backplane) — You can replace it under power if your AC500 rack supports live insertion—handy during shift changes when downtime is costly.

- Integrated status LEDs (BUS OK, TERM, ERROR) — Real-time visual feedback saves 10–15 minutes per troubleshooting session. One customer told me they stopped carrying a multimeter just for bus diagnostics after switching to BCU-12-equipped racks.

- Backplane-mounted, DIN-rail compatible — Fits seamlessly into standard AC500 modular enclosures without adapters or custom brackets. Mounting depth is shallow (~85 mm), so it plays well in space-constrained control panels.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB BCU-12 |

| HS Code | 8537.10.90 (Control boards for industrial automation systems) |

| Power Requirements | Supplied via AC500 backplane (24 VDC, typical current draw: 35 mA) |

| Dimensions (W × H × D) | 25 mm × 125 mm × 85 mm (standard 1-module width) |

| Weight | Approx. 180 g |

| Operating Temperature | −25 °C to +60 °C (derating applies above 55 °C) |

| Signal Input/Output | Isolated RS-485 bus interface (AC500 internal bus protocol); no analog or digital I/O |

| Communication Interfaces | Dedicated AC500 system bus only — not Ethernet-, CAN-, or Modbus-capable |

| Installation Method | DIN rail (TS35) mounting; snaps directly onto AC500 base units or extension modules |

Application Fields

The BCU-12 shines where bus reliability trumps flexibility—think distributed I/O cabinets spread across large machinery frames, HVAC plant control networks with multiple AC500 sub-racks, or legacy brownfield upgrades where you’re extending an existing AC500 backbone without overhauling the entire architecture. It’s commonly used in food & beverage lines (especially where washdown zones require physical separation of bus segments), municipal pump stations, and material handling conveyance systems. From my experience, engineers reach for it most often when they need to isolate noise-prone motor drives from sensitive analog sensor buses—or when adding remote I/O without introducing timing jitter.

Advantages & Value

If you’re evaluating this against generic bus repeaters or unbranded couplers, here’s what stands out: full firmware-level compatibility with AC500 CPU modules (no version mismatches), consistent impedance matching across batches (critical for bus stability at 1 Mbps), and ABB’s documented support lifecycle—this part has been in production since 2014 with no known obsolescence notices. Procurement-wise, it avoids the hidden cost of re-engineering bus layouts or retrofitting termination kits later. And because it’s built into ABB’s spare parts ecosystem, lead times are predictable: we typically ship in-stock units within 5–7 business days. In many cases, buying one BCU-12 upfront saves hours of bus fault tracing down the line.

Installation & Maintenance

Mount it in a clean, dry cabinet meeting IP54 minimum (though IP65 is preferred if near washdown areas). Ensure ≥50 mm clearance above/below for convection cooling—heat buildup degrades termination resistor accuracy over time. Wiring is straightforward: just connect the AC500 backplane rails (no external power or grounding wires needed). Safety-wise, always power down the rack before installing/removing—despite hot-swap capability, backplane arcing remains a risk with poor contact alignment. For maintenance: visually inspect LEDs quarterly; wipe dust off the module surface every 6 months (compressed air works fine); and verify bus integrity using ABB’s Automation Builder diagnostic tools during annual firmware updates (no user-serviceable parts inside—don’t open the housing).

Quality & Certifications

CE marked (2014/30/EU, 2011/65/EU), UL 508 listed (E205262), RoHS 3 compliant, and manufactured under ISO 9001:2015. ABB backs it with a standard 365-day warranty—same as all AC500 system components. We handle replacements directly: if a unit fails within warranty, we’ll ship a verified replacement within 48 hours of confirmation (FedEx/UPS/DHL, depending on destination). No RMA forms, no waiting for approvals—just drop us a photo of the failed unit’s label and a short description of the symptom.

Our order placement process: 50% advance payment required to confirm stock reservation; balance due before dispatch. In-stock units ship within 1 week. If out-of-stock, maximum wait is 30 calendar days—we’ll notify you proactively and offer alternatives if timelines tighten. Express delivery via FedEx, UPS, or DHL available globally.

Reviews

There are no reviews yet.