Description

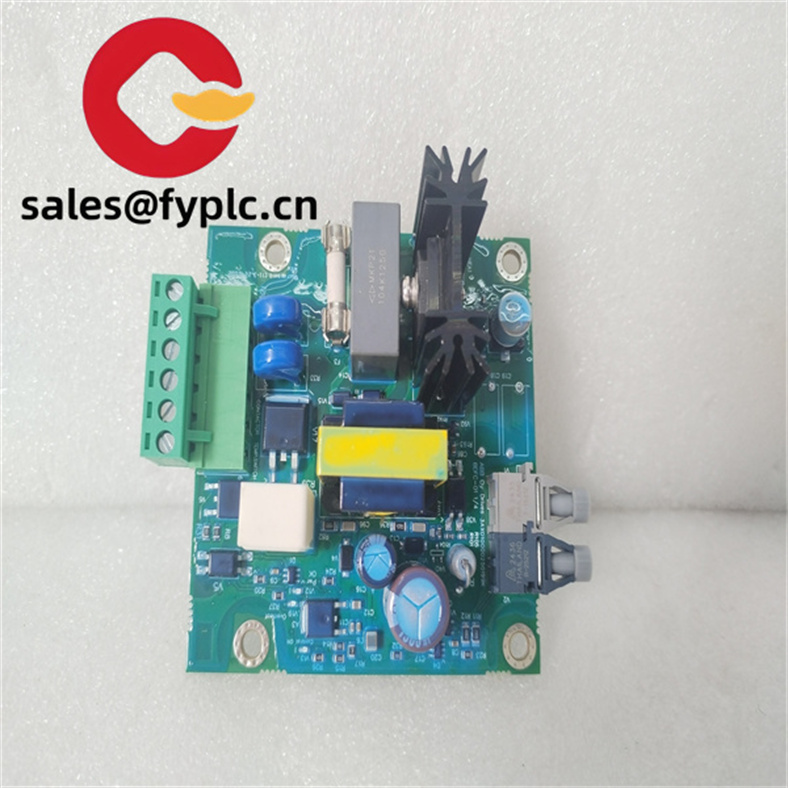

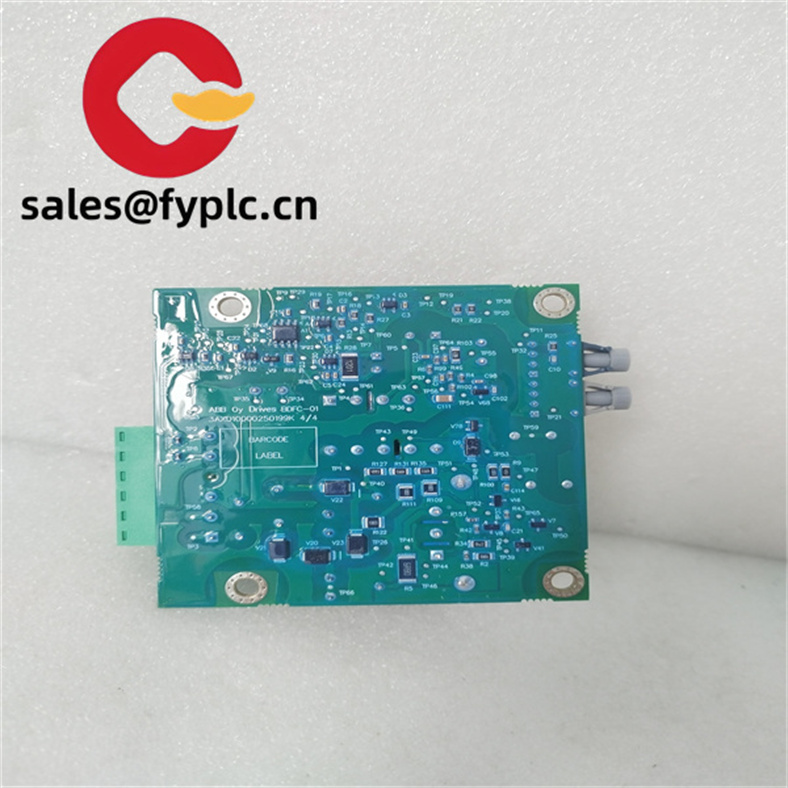

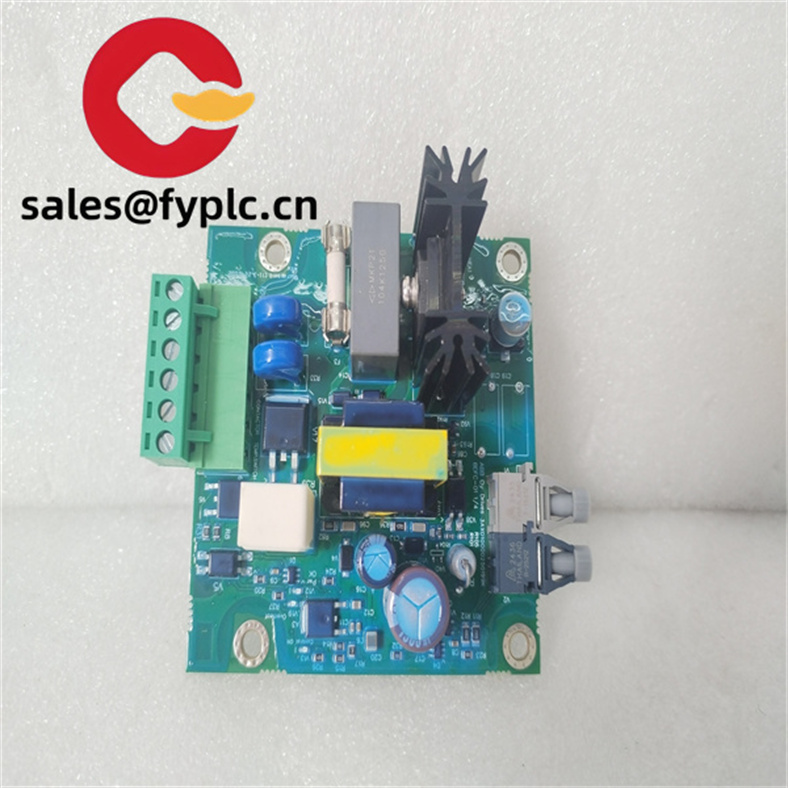

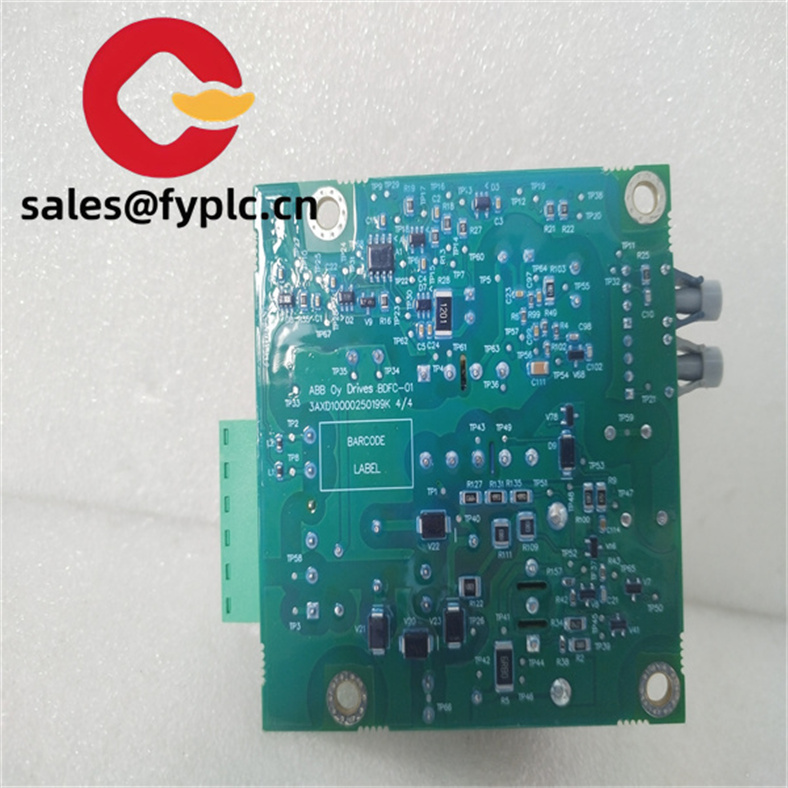

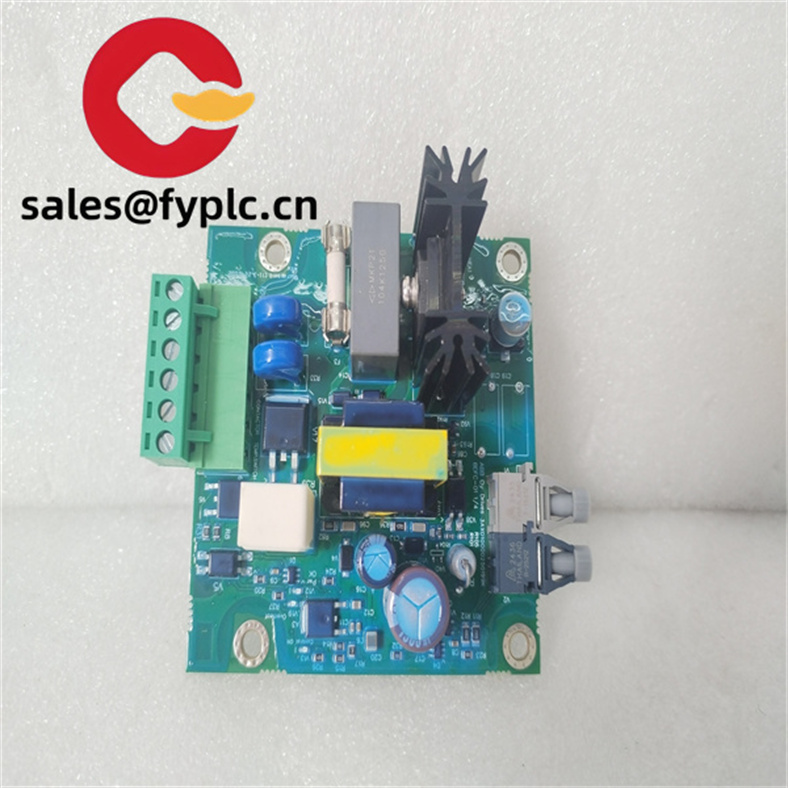

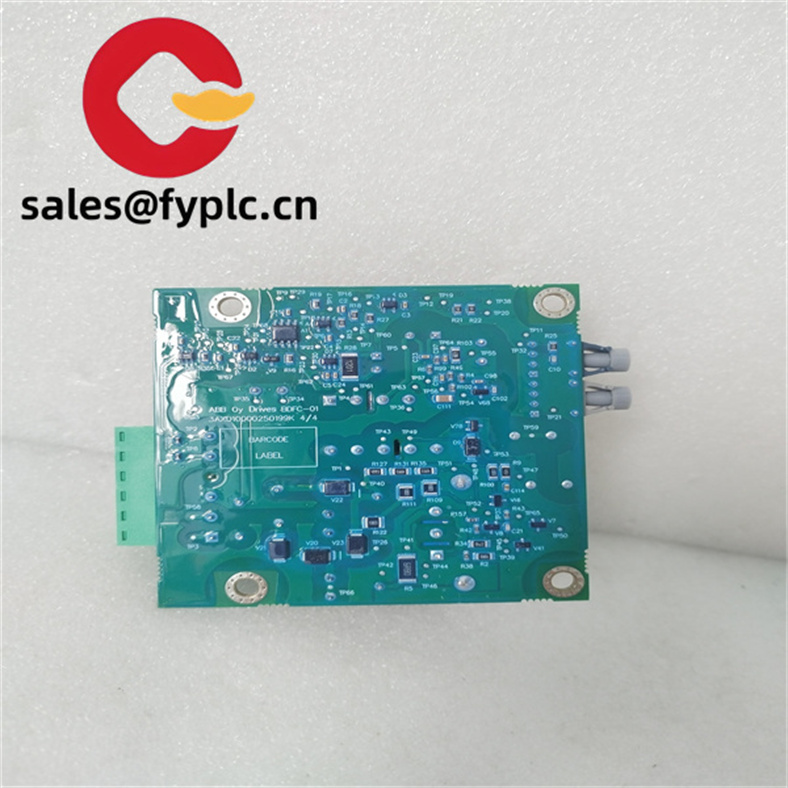

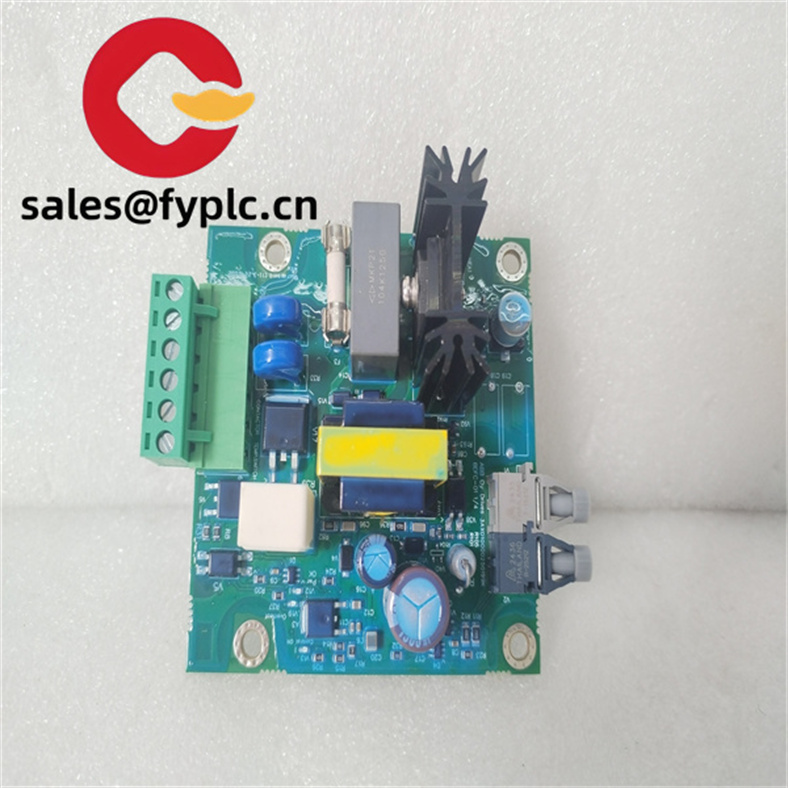

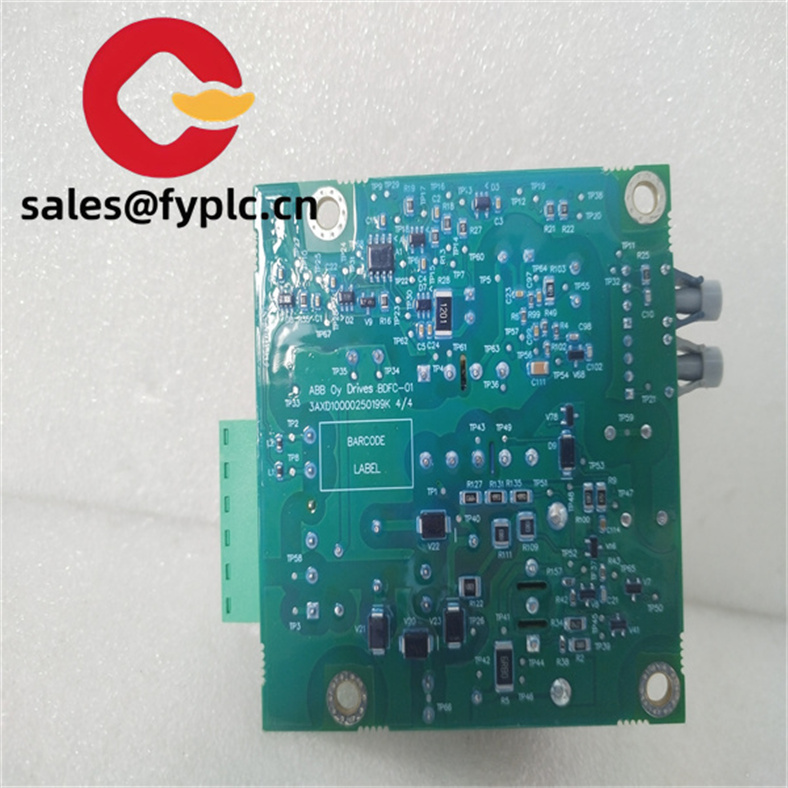

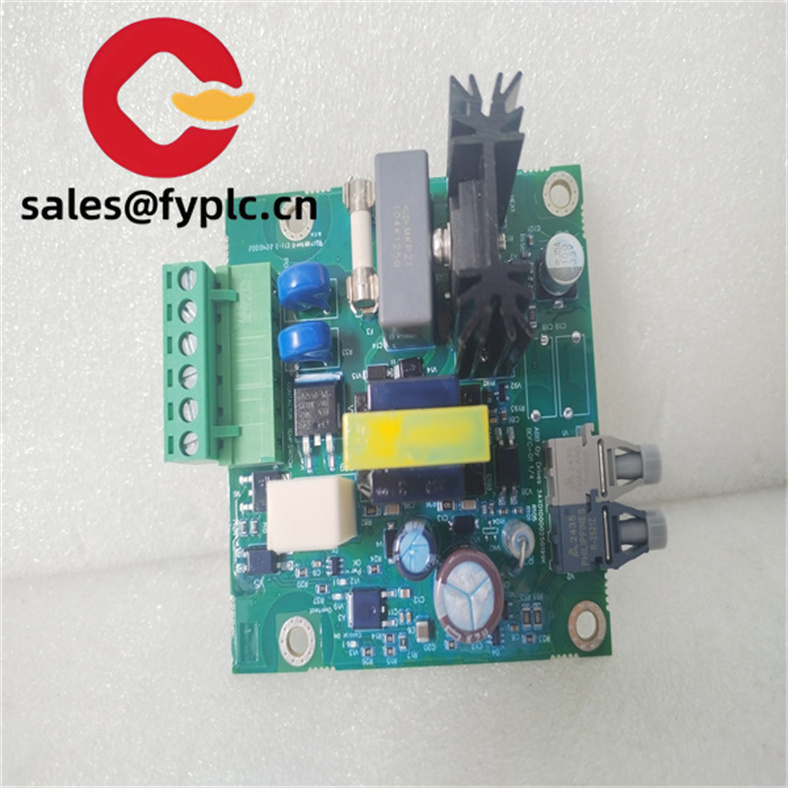

ABB BDFC-01C inverter control board

In the intricate landscape of industrial automation, where seamless control and reliable performance are the cornerstones of success, the ABB BDFC-01C emerges as a game – changing solution. ABB, a renowned global leader in power and automation technologies, has engineered the BDFC-01C to meet the diverse and exacting demands of modern industrial drive systems. This advanced device is not just another component; it’s a vital cog in the machinery of industrial control, designed to enhance operational efficiency, improve process reliability, and drive productivity to new heights.

The ABB BDFC-01C is a specialized drive control unit, meticulously crafted to manage and optimize the performance of industrial electric drives. It serves as the interface between the control system and the drive, ensuring precise regulation of motor speed, torque, and direction. Whether integrated into a large – scale manufacturing plant’s production line, a complex material handling system, or a high – precision machining setup, the BDFC-01C plays a crucial role in maintaining smooth and efficient operation. In the context of broader industrial control systems, it acts as a key enabler, facilitating seamless communication between different components and enabling real – time adjustments to optimize drive performance.

The ABB BDFC-01C stands out in real – world industrial environments with its exceptional functional strengths and innovative design. This unit has been engineered to deliver lightning – fast response times, allowing it to react instantly to changes in the control signals. In high – speed manufacturing operations, this rapid response ensures that the drive system can adjust to varying load conditions without any lag, minimizing production disruptions and enhancing overall throughput.

Resilience is another defining characteristic of the BDFC-01C. Built with high – quality components and a robust architecture, it can withstand the harsh conditions typically found in industrial settings, including electrical noise, vibrations, and temperature fluctuations. Operators benefit from its reliable performance over extended periods, reducing the frequency of maintenance and replacement, and ultimately minimizing downtime.

Interoperability is at the heart of the ABB BDFC-01C‘s design. It can seamlessly integrate with a wide range of ABB drives, as well as third – party devices, providing flexibility in system design and expansion. Whether upgrading an existing drive system or building a new one from scratch, the BDFC-01C ensures smooth communication and 协同 operation between different components, making it a versatile choice for any industrial automation project.

The ABB BDFC-01C finds extensive applications across diverse industries, delivering significant value in each. In the manufacturing sector, it is commonly used to control the speed and torque of motors in conveyor systems, robotic arms, and machine tools. For example, in an automotive assembly plant, the BDFC-01C can precisely regulate the movement of robotic arms, ensuring accurate and consistent assembly of vehicle components. This not only improves product quality but also reduces production costs by minimizing waste and rework.

In the material handling industry, the BDFC-01C plays a crucial role in optimizing the performance of cranes, hoists, and conveyor belts. By accurately controlling the drive system, it enables smooth and efficient movement of materials, reducing the risk of accidents and improving overall operational safety. In a large – scale warehouse, the BDFC-01C can ensure that conveyor belts operate at the optimal speed, maximizing throughput and minimizing energy consumption.

- BDFC-02C – An upgraded version with enhanced processing power and additional input/output channels, ideal for more complex drive control applications.

- BDFC-01D – A variant with advanced diagnostic capabilities, allowing for quicker identification and resolution of drive system issues.

- BDFC-03C – Features improved energy efficiency, making it a sustainable choice for industries looking to reduce their carbon footprint.

- BDFC-01E – A more compact model, suitable for space – constrained industrial setups without sacrificing core functionality.

- BDFC-04C – Optimized for use in hazardous environments, with additional safety features to meet strict industry standards.

- BDFC-01F – Comes with integrated cloud connectivity, enabling remote monitoring and control of drive systems for enhanced convenience and productivity.

Installing the ABB BDFC-01C requires careful attention to detail. When mounting it on a DIN – rail, ensure that the rail is securely fastened and free from any debris that could interfere with the module’s operation. Make sure to follow the wiring diagrams provided in the user manual when making electrical connections, and ensure proper grounding to protect the unit from electrical surges.

For long – term operation, regular maintenance of the BDFC-01C is essential. Periodically inspect the module for any signs of physical damage, such as cracks or loose connections. Check the status indicators regularly to ensure that it is operating within normal parameters. It is also advisable to update the module’s firmware as per ABB’s recommendations. Firmware updates often bring performance enhancements, security patches, and compatibility improvements, ensuring that the ABB BDFC-01C continues to perform reliably throughout its lifespan.

For more information, please click below to learn more:

.韩芳婷.20250317.171207-3.jpg)

Reviews

There are no reviews yet.