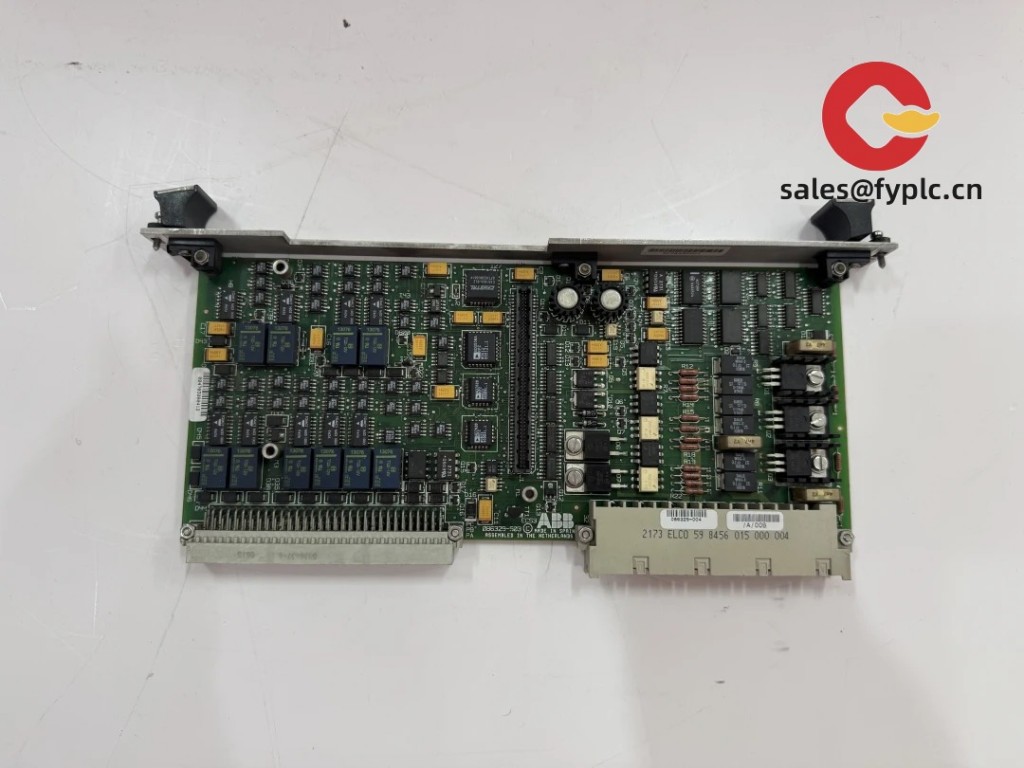

Description

ABB CB801 – CompactBridge Module for DeviceNet to CIP Integration

If you’re working on integrating legacy DeviceNet devices into a modern ControlNet or EtherNet/IP environment, the ABB CB801 typically comes up as a solid bridge solution. From my experience in industrial networking upgrades, this module seems to be one of those quiet workhorses—small in size but critical in function. It’s not flashy, but when you need seamless communication between older I/O systems and newer controllers, it often makes the difference between a messy workaround and a clean integration.

Key Features

- DeviceNet to CIP Translation – Converts DeviceNet I/O data into Common Industrial Protocol (CIP) messages, allowing older sensors and actuators to communicate directly with Logix5000 controllers.

- Compact Design – One thing I appreciate is how it fits neatly into tight control cabinets without requiring additional DIN rail space or external power supplies in most cases.

- Diagnostics & Status Indicators – LED feedback for network status, node health, and communication errors helps reduce troubleshooting time during commissioning or faults.

- No Programming Required – Seems to be configured entirely through RSLinx or Studio 5000, which simplifies setup compared to modules that need script-based configuration.

- Peer-to-Peer Messaging Support – Enables direct device-level messaging between nodes, which can be useful in distributed architectures where PLCs don’t need to mediate every exchange.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / CB801 |

| HS Code | 8537.10.90 (Control panels incorporating semiconductor devices) |

| Power Requirements | 24V DC from backplane (no external supply needed under normal load) |

| Dimensions & Weight | Approx. 70 mm H × 45 mm W × 85 mm D / 280 g |

| Operating Temperature | 0°C to 60°C (standard industrial range) |

| Signal Input/Output Types | Digital I/O via DeviceNet slave mapping |

| Communication Interfaces | DeviceNet (slave), Ethernet/IP (adapter mode), CIP-compliant messaging |

| Installation Method | DIN rail mount (with included clip); connects via 40-pin connector to compatible chassis |

Application Fields

The CB801 shows up most often in brownfield manufacturing environments—think automotive assembly lines, packaging systems, or material handling setups where some equipment still runs on DeviceNet. In many cases, users deploy it when upgrading a central controller to a ControlLogix or CompactLogix platform but want to retain existing DeviceNet nodes like photoelectric sensors, motor starters, or valve islands. It’s also been used in wastewater treatment plants where remote I/O pods are spread across large sites and replacing cabling isn’t cost-effective.

Advantages & Value

One real benefit from a procurement standpoint is longevity—Rockwell tends to support these bridge modules longer than third-party equivalents. You might notice that compatibility with Studio 5000 means fewer integration surprises down the road. While not the cheapest option upfront, the reduction in engineering hours during retrofit projects usually offsets the initial cost. Also, since it avoids protocol gateways with proprietary firmware layers, long-term maintenance risks tend to be lower.

Installation & Maintenance

Install it in a standard Type 1 or Type 12 enclosure with adequate airflow—don’t stack it too close to high-heat components like drives or transformers. Wiring is straightforward: just connect the DeviceNet trunkline using twisted pair with proper termination, and ensure shield grounding follows Rockwell’s guidelines to avoid noise issues. For maintenance, check the LEDs periodically during walkthroughs. Firmware updates are rare but do exist; keep an eye on Rockwell Knowledgebase alerts. Calibration isn’t required, though cleaning dust buildup every 12–18 months helps prevent thermal throttling in hotter environments.

Quality & Certifications

Certified to CE, UL 508, and RoHS standards—so it meets both North American and EU safety requirements. The build quality feels consistent with other Allen-Bradley components: rugged housing, reliable connectors, and good labeling. Warranty covers 365 days from shipment date, covering defects in materials and workmanship under normal use. No extended warranties are offered through standard channels, but replacement units ship quickly if needed.

Order Placement Process and Guarantees

Units in stock typically ship within one week. For out-of-stock items, lead time won’t exceed four weeks. Payment terms require 50% upfront, with the balance due before dispatch. We only use FedEx, UPS, or DHL for express delivery—no freight-only options at this level. Tracking is provided automatically, and all units are tested before packing.

Reviews

There are no reviews yet.