Description

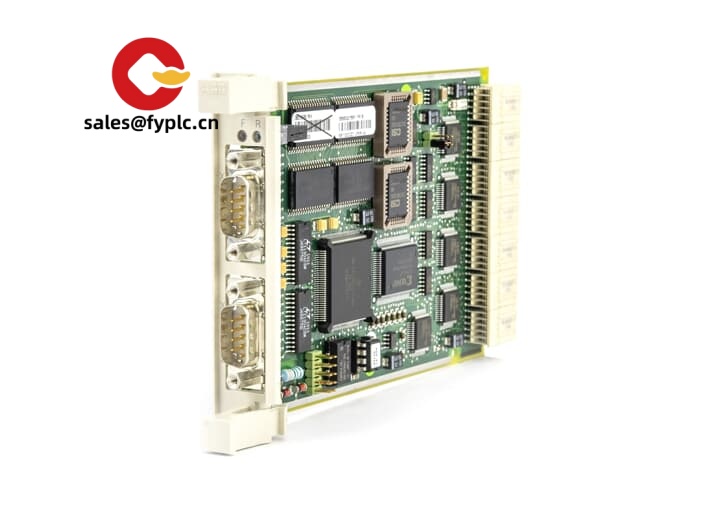

ABB CI535V24 (3BSE022158R1) – V.24/RS‑232 Communication Interface Module for Industrial DCS/PLC Integration

The ABB CI535V24 brings V.24 (RS‑232) serial connectivity into ABB control systems, making it practical to connect legacy serial instruments, barcode/RFID readers, printers, modems, weigh scales, or specialized analyzers without redesigning the whole architecture. From my experience, this module is typically used in ABB DCS/PLC environments (such as Freelance or Advant/AC installations) when you need reliable point-to-point serial links and controller-level configuration for protocols like Modbus RTU/ASCII.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- V.24/RS‑232 serial interface – Designed for point‑to‑point serial communication with common industrial and lab devices.

- Controller‑level protocol handling – In many cases supports Modbus RTU/ASCII or vendor protocols via the controller’s configuration, reducing gateway costs.

- Backplane powered – Typically powered through the ABB system backplane, simplifying cabinet wiring.

- Industrial temperature range – Suitable for standard cabinet environments; ideal for factory floors and utilities.

- Plug‑in installation – Fits the ABB system rack/backplane so you can add serial ports without expanding third‑party hardware.

- Service-friendly – Clear port labeling and straightforward commissioning; technicians usually have it talking within minutes.

Technical Specifications

| Brand / Model | ABB CI535V24 |

| Part Number | 3BSE022158R1 |

| HS Code | 8537.10 (Programmable control/industrial control assemblies) |

| Power Requirements | 24 V DC via system backplane (typical for ABB modules) |

| Operating Temperature | Typically 0…+55 °C (cabinet installation) |

| Signal I/O Types | Serial data, V.24 (RS‑232), asynchronous |

| Communication Interfaces | V.24/RS‑232 physical layer; controller‑configured protocols (e.g., Modbus RTU/ASCII, device‑specific) |

| Installation Method | Mounted on ABB system rack/backplane within a protected control cabinet |

Application Fields

Plants often keep a mix of new and legacy equipment. You might notice this module shows up where a controller needs to talk to single‑drop serial devices:

- Process industries (chemicals, pharma, food) – connect analyzers, weigh scales, or label printers over RS‑232.

- Water & wastewater – link flow totalizers, sampling units, and older telemetry modems.

- Power & utilities – interface to protective relays or gateway devices still on serial ports.

- Discrete manufacturing – barcode/RFID readers, PLC‑to‑PLC serial links, test rigs.

- Terminals & logistics – serial printers and handheld docking cradles.

Advantages & Value

- Reliability – Purpose‑built for ABB systems, so it behaves predictably in continuous operation.

- Compatibility – Matches ABB controller tooling and diagnostics; fewer surprises during commissioning.

- Cost savings – Avoids external protocol converters for many RS‑232 tasks; less hardware, less wiring.

- Lifecycle support – Easier spares strategy across multiple plants standardizing on ABB.

- Clean cabinet layout – Backplane power and integration reduce clutter and heat points in the panel.

Installation & Maintenance

- Cabinet standards – Install in a clean, dry control cabinet with adequate ventilation; follow ABB’s rack/backplane guidelines.

- Wiring – Use shielded serial cables for RS‑232 runs; keep cable lengths within RS‑232 recommendations. Ground shields at one end to avoid loops.

- Power – Module is typically powered from the system backplane; verify power budget of the rack before adding modules.

- Safety – De‑energize the rack before insertion/removal. Observe ESD handling procedures.

- Configuration – Match baud rate, data bits, parity, and stop bits with the field device. If using Modbus, define master/slave role and timeouts carefully.

- Routine checks – Periodically verify connectors are tight and clean; review controller diagnostics for framing errors or overruns.

- Firmware/tooling – Keep controller engineering tools updated; in most cases updates improve serial driver stability.

Quality & Certifications

- CE marked

- UL (Recognized/Listed, model dependent)

- RoHS compliance typical for this series

- Manufactured under ISO 9001 quality management

- Manufacturer warranty: 365 days (provided with purchase)

One thing I appreciate is how this module keeps older serial devices viable during phased modernizations. If you’re trying to avoid a rip‑and‑replace, the CI535V24 is usually the most straightforward way to bridge that gap.

Reviews

There are no reviews yet.