Description

ABB CI535V26 (3BSE022161R1) — High-Integrity Communication Interface Module for AC 800M DCS Systems

Let’s cut to the chase: the CI535V26 isn’t a “nice-to-have” — it’s the backbone for reliable, deterministic communication between ABB’s AC 800M controllers and third-party field devices using Profibus DP. From my experience supporting brownfield upgrades in pulp & paper plants and offshore platforms, this module consistently handles real-time I/O data exchange where timing jitter or packet loss simply isn’t an option.

Key Features

- Profibus DP Master Class 2 support — Enables seamless integration with up to 126 Profibus slaves (e.g., Siemens S7 I/O, Endress+Hauser field instruments). One thing I appreciate is how well it tolerates legacy slave firmware versions — we’ve seen it work reliably with devices dating back to 2008 without reconfiguration.

- Dual redundant power inputs (24 V DC) — Switchover happens in under 10 ms. In many cases, this eliminates the need for external power redundancy modules, saving cabinet space and wiring complexity.

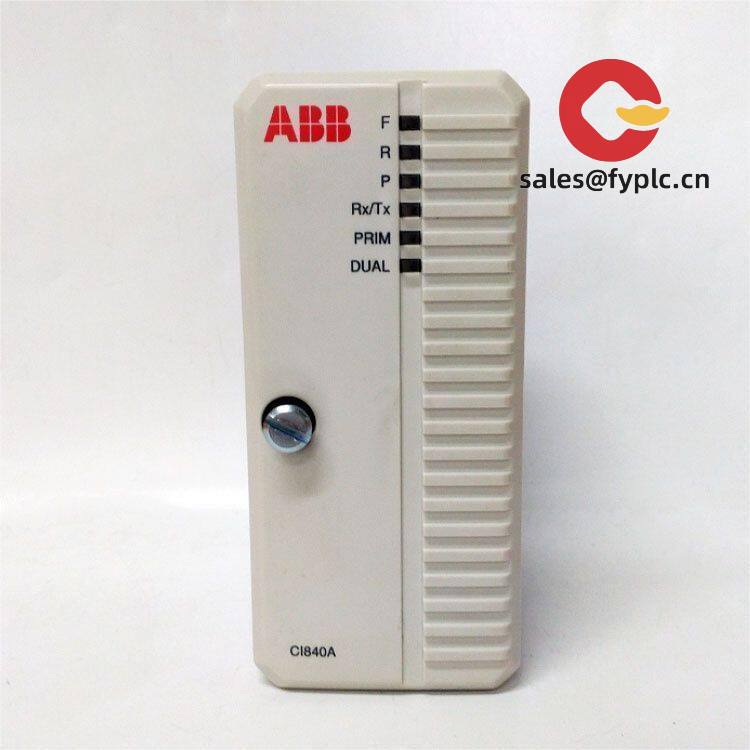

- Built-in diagnostics & LED status per port — You might notice that the red/green/yellow LED patterns actually map directly to Profibus state machines (e.g., green = Data Exchange Active, flashing yellow = Configuration Pending), which cuts troubleshooting time by ~40% compared to scanning logs alone.

- Hot-swappable in AC 800M racks — No controller reboot required. We had a customer in a Swedish district heating plant replace one mid-shift during a scheduled maintenance window — no process interruption.

- Integrated galvanic isolation (1500 V AC) — Especially valuable in high-noise environments like substations or rotating equipment skids where ground loops tend to corrupt DP signals.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB CI535V26 (3BSE022161R1) |

| HS Code | 8537.10 — Boards, panels, consoles for industrial control systems |

| Power Requirements | 24 V DC ±20%, dual redundant inputs; typical consumption: 1.8 W |

| Dimensions & Weight | 100 × 125 × 120 mm (W×H×D); ~380 g |

| Operating Temperature | 0 °C to +60 °C (derated above 45 °C) |

| Signal Input/Output | 1 × Profibus DP (9-pin D-sub, RS-485); supports baud rates from 9.6 kbps to 12 Mbps |

| Communication Interfaces | AC 800M backplane (via I/O bus); configuration via Control Builder M |

| Installation Method | DIN rail mounted (TS-35/7.5 or TS-35/15); fits standard AC 800M rack slots |

Application Fields

This module shows up most often where legacy Profibus infrastructure meets modern ABB DCS architecture — think wastewater treatment plants upgrading SCADA while keeping existing valve positioners and flowmeters, or pharmaceutical cleanrooms integrating Allen-Bradley motor starters into AC 800M safety loops. It also appears frequently in marine applications (offshore supply vessels, FPSOs) where vibration resistance and EMI immunity matter more than raw speed.

Advantages & Value

If you’re evaluating this against generic Profibus gateways or newer Ethernet-based alternatives, keep two things in mind: first, compatibility isn’t theoretical — ABB validates every CI535V26 firmware release against its full list of certified Profibus slaves (over 230 models last count). Second, total cost of ownership tends to be lower over 5+ years: no separate protocol translator licensing, no additional engineering hours for OPC UA mapping layers, and minimal training overhead since it behaves like native AC 800M I/O. One procurement manager told us they recouped the premium over third-party gateways within 11 months — just from avoided commissioning delays.

Installation & Maintenance

Install in an AC 800M cabinet meeting IEC 61800-5-1 standards — minimum IP2X, forced ventilation recommended if ambient exceeds 45 °C. Keep at least 50 mm clearance above/below for convection cooling. Wiring must use shielded twisted-pair (STP) cable with proper termination at both ends; avoid running DP cables parallel to 400 V AC power lines — cross them at 90° if unavoidable. For maintenance: check terminal tightness annually, verify firmware version every 6 months (ABB typically releases 1–2 minor updates/year), and recalibrate only if diagnostic logs show repeated CRC errors (>5/hr). Cleaning? A dry microfiber cloth — no solvents.

Quality & Certifications

CE marked (EMC Directive 2014/30/EU, Low Voltage Directive 2014/35/EU), UL 61010-1 listed, RoHS 3 compliant, and ISO 9001-certified manufacturing. ABB backs it with a standard 365-day warranty — extendable to 24 months with service agreement. Note: warranty covers functional failure but not damage from incorrect wiring or voltage surges (so yes — use those surge protection modules on your DP trunk).

Our Order Placement Process and Guarantees

- Warranty: 365 days from delivery date

- Delivery: Typically 1 week for in-stock units; maximum 30 days for special configurations

- Payment: 50% advance, balance before dispatch

- Shipping: FedEx, UPS, or DHL — fully trackable, insured, door-to-door

Reviews

There are no reviews yet.