Description

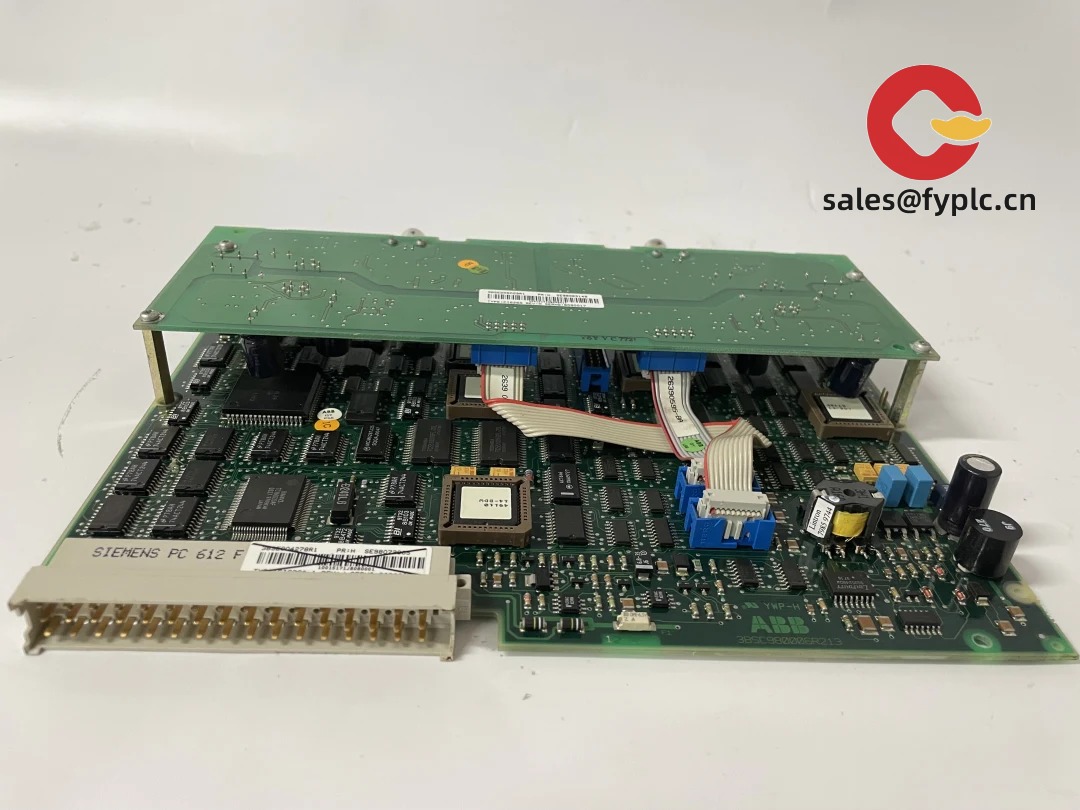

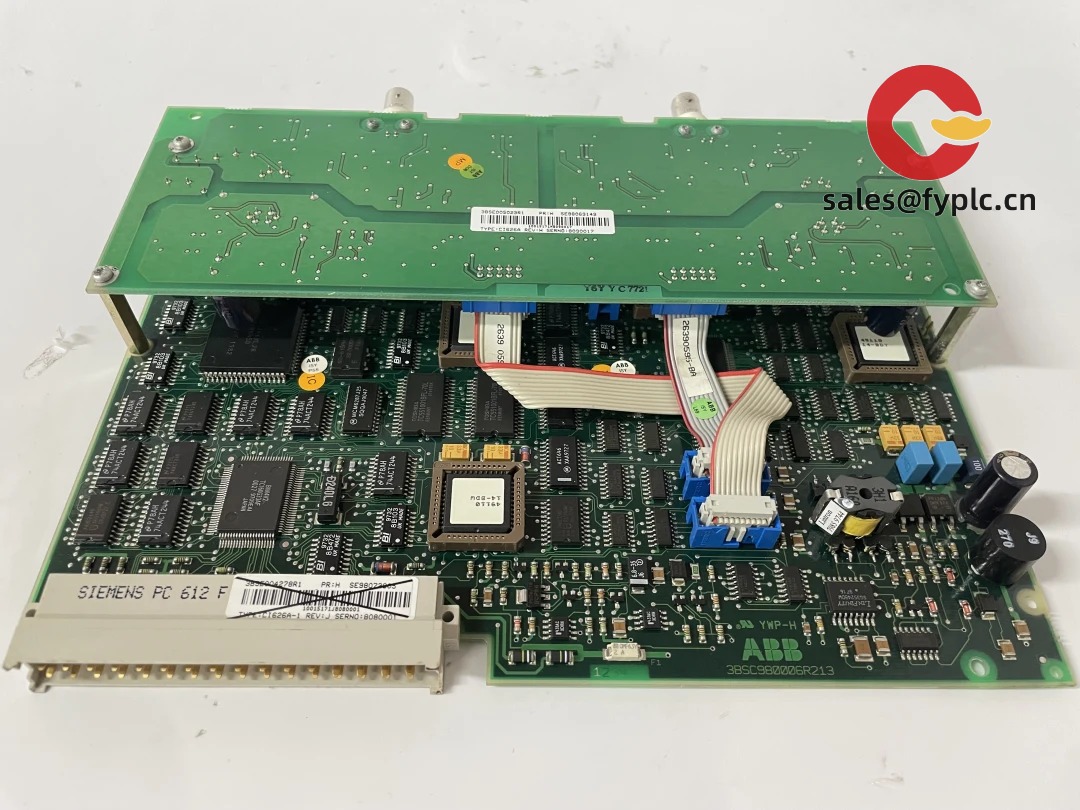

ABB CI626A (3BSE005029R1) – AF 100 Fieldbus Interface for AC 800M Migration and Expansion

The ABB CI626A is a communication interface module designed to connect an AC 800M controller to an AF 100 fieldbus segment, which you’ll still find in many Advant and brownfield installations. From my experience, it’s the practical way to bridge AC 800M-based systems with existing AF 100 networks without ripping and replacing what’s already stable. You might notice that commissioning stays straightforward in Control Builder M, and diagnostics are clear enough to speed up FAT/SAT work.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

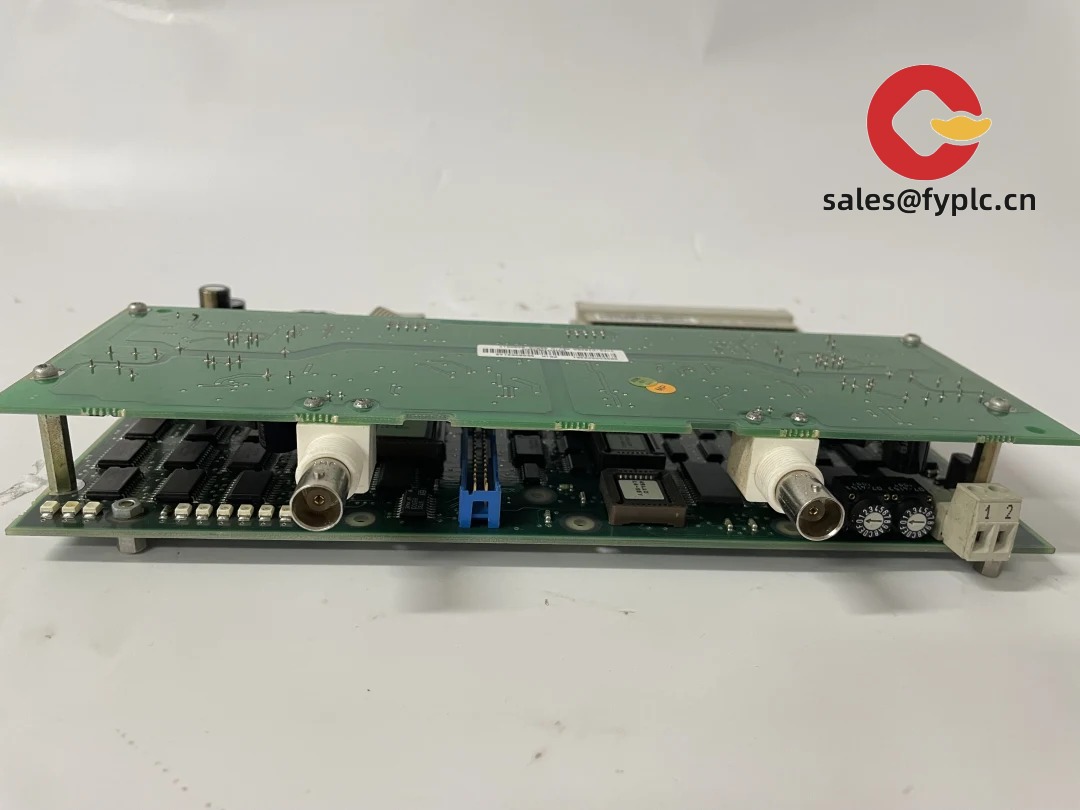

- AF 100 connectivity – Interfaces AC 800M to legacy AF 100 segments, ideal for Advant/AC 400 migration paths.

- Deterministic cyclic data exchange – Stable and predictable data handling for process signals and interlocks.

- Engineering in Control Builder M – Parameterization and diagnostics through familiar ABB tools, typically with clear status/LED indications.

- Backplane-powered – No external power supply; the module draws power from the AC 800M base for clean cabinet layouts.

- Robust EMC design – Galvanic isolation on the fieldbus side helps reduce noise and ground-loop issues in real plants.

- Supports redundant architectures – In many cases, can be deployed within redundant AC 800M controller setups to maintain availability.

Technical Specifications

| Brand / Model | ABB CI626A, Part No. 3BSE005029R1 |

| HS Code | 8537.10 (Programmable control/industrial control assemblies) |

| Power Requirements | Powered from AC 800M backplane; no external supply required (typical) |

| Operating Temperature | 0 to +55 °C (typical for ABB CI modules) |

| Signal I/O Types | AF 100 fieldbus segment (field side); AC 800M system backplane (controller side) |

| Communication Interfaces | AF 100 bus port; diagnostics via Control Builder M / 800xA tools |

| Installation Method | DIN-rail on AC 800M base; install in a ventilated control cabinet |

Application Fields

This module is commonly used in brownfield modernization where AF 100 devices must remain in service while an AC 800M or 800xA system is introduced. Typical plants include:

- Refining and chemicals where AF 100-connected MCCs or remote I/O panels still run reliably

- Pulp & paper mills migrating Advant-based areas to AC 800M with staged cutovers

- Power and water utilities keeping legacy AF 100 networks during phased DCS upgrades

One thing I appreciate is how it trims commissioning time in plants where documentation is a bit dated—the CI626A’s diagnostics and predictable cyclic exchange make loop checks more tolerable.

Advantages & Value

- Protects existing assets – Leverage installed AF 100 networks without wholesale replacement.

- Lower project risk – Stepwise migration from Advant to AC 800M/800xA reduces outage windows.

- Compatibility – Works within the ABB control ecosystem; engineering and service teams are usually familiar with the toolchain.

- Lifecycle support – Access to ABB’s extended support and spares helps with long-running plants.

- Total cost benefits – Keeping field wiring and AF 100 devices in place often saves both CAPEX and commissioning hours.

Installation & Maintenance

- Cabinet environment – Mount on DIN-rail inside an IP-rated cabinet. Provide ventilation to keep ambient within 0…55 °C.

- Wiring & shielding – Use shielded twisted pair for AF 100 per ABB guidelines. Bond shields at a single point to avoid loops.

- Grounding – Ensure proper PE connection and segregation from high-voltage cables to minimize EMC issues.

- Redundancy – If used in redundant AC 800M setups, follow ABB channel separation practices and label segments clearly.

- Maintenance – Periodically verify bus integrity (terminations, shield continuity), clean dust from vents, and keep firmware/project backups aligned with change control.

- ESD handling – Treat the CI626A as ESD-sensitive when installing or replacing.

Quality & Certifications

- CE marked (EMC and Safety) – typical for ABB AC 800M modules

- UL/cUL Listed (industrial control equipment) – commonly applied for North America

- RoHS compliant manufacturing

- Produced under ISO 9001 quality systems

- Manufacturer warranty: 12 months (365 days)

Related and Supporting Components

- AC 800M CPUs: PM861/PM864/PM865 series for controller execution and redundancy options.

- Engineering Tools: Control Builder M / ABB 800xA engineering for configuration and diagnostics.

- Cabling & Termination: Shielded twisted pair AF 100 cable, approved terminators/repeaters as per segment length and topology.

Reviews

There are no reviews yet.