Description

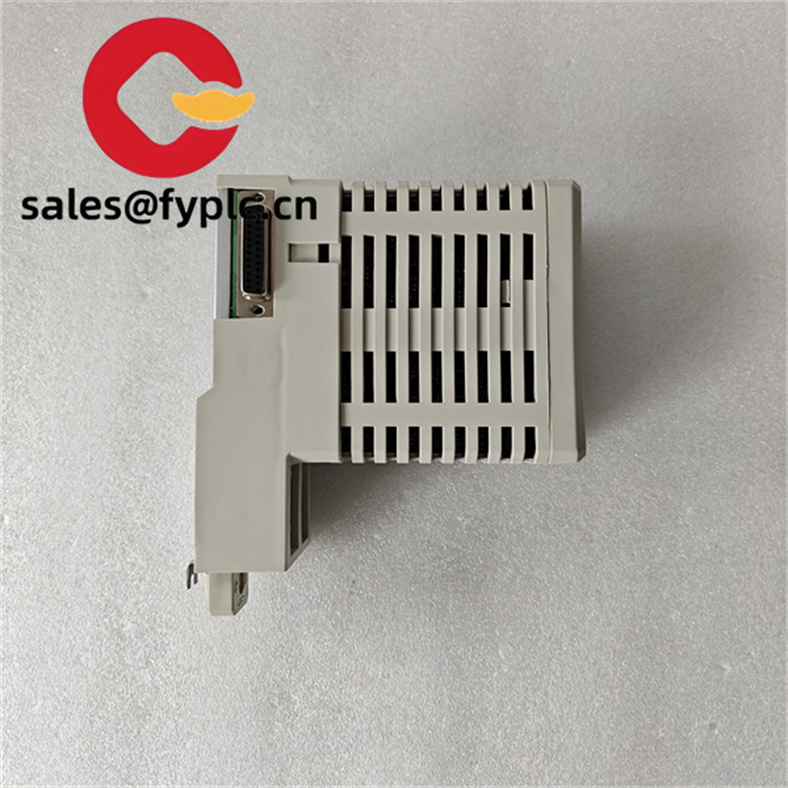

ABB CI840 Tension Controller System Redundant Wiring Module

In the dynamic and complex realm of industrial automation, where the seamless flow of data is the lifeblood of efficient and reliable operations, the ABB CI840 emerges as a paragon of innovation and performance. ABB, a globally revered leader in power and automation technologies, has meticulously engineered the CI840 to meet the most exacting demands of modern industrial control landscapes. This module is not merely a component; it serves as the linchpin that enables smooth, high – speed, and secure communication between diverse devices within an industrial ecosystem, thereby ensuring the seamless orchestration of industrial processes across a wide spectrum of sectors.

The ABB CI840 is a highly specialized Profibus DP – V1 communication interface module. Its fundamental role is to act as a bridge, facilitating the rapid and accurate transfer of data between the control system, such as ABB’s advanced AC 800m controller family, and an extensive array of field devices. Whether it’s establishing connectivity with sensors that monitor critical process variables like temperature, pressure, and flow rate, actuators that execute control actions to regulate machinery, or other intelligent devices distributed throughout an industrial network, the CI840 plays an indispensable and central role. It is seamlessly integrated into large – scale Distributed Control Systems (DCS) in industries as diverse as chemical manufacturing, Supervisory Control and Data Acquisition (SCADA) systems in power generation plants, or Programmable Logic Controller (PLC) – based setups in manufacturing facilities. By enabling real – time and bidirectional communication, it empowers operators to monitor and control processes with unparalleled precision, leading to enhanced productivity, improved process stability, and optimized resource utilization.

|

Label

|

Specification

|

|

Model Number

|

CI840

|

|

Brand

|

ABB

|

|

Type

|

Profibus DP – V1 Communication Interface Module

|

|

Input Voltage

|

Operates on 24V DC, with an operating range typically spanning from 19.2V to 30V, ensuring compatibility with standard industrial power supplies

|

|

Operating Temp

|

Can function within a wide temperature range of – 40 °C to + 70 °C (- 40 °F to + 158 °F), making it suitable for even the harshest industrial environments, whether in cold storage facilities or high – temperature processing plants

|

|

Communication Method

|

Utilizes the Profibus DP – V1 protocol, a highly prevalent and reliable industrial communication standard known for its high – speed data transfer capabilities and broad device compatibility

|

|

Mounting

|

Designed with an ergonomic form factor that allows for easy installation within standard control cabinets. It can be securely fastened, minimizing vibrations and ensuring stable operation

|

|

Weight

|

Approximately 0.3 kg (0.66 lbs), which is relatively lightweight, facilitating convenient handling during installation, maintenance, and system upgrades

|

|

Certifications

|

Complies with international standards such as EN 61010 – 1 and UL 61010 – 1. These certifications guarantee that the CI840 meets strict safety, quality, and electromagnetic compatibility requirements, ensuring its safe and reliable operation in industrial settings

|

|

Dimensions

|

Measures 12.7 cm (5.0 inches) in length, 7.6 cm (3.0 inches) in width, and 12.7 cm (5.0 inches) in height. Its compact size enables efficient use of space within control cabinets, making it suitable for both new installations and retrofitting existing systems

|

|

IP Rating

|

Although details about the exact IP rating may vary, it is generally designed for indoor use, with appropriate protection against dust and limited access to electrical components, safeguarding its internal circuitry from environmental contaminants

|

|

Protocols Supported

|

Primarily supports the Profibus DP – V1 protocol, which enables seamless compatibility with a vast array of industrial devices and systems. This support ensures that the CI840 can integrate with a wide range of field devices, control systems, and other components within an industrial automation infrastructure

|

The ABB CI840 showcases a plethora of remarkable functional strengths and design advantages that set it apart in real – world industrial environments. Engineered for high – speed data transfer, it can achieve data rates of up to 12 Mbit/s. This lightning – fast data transfer capability is of utmost importance in fast – paced manufacturing lines, where real – time data is crucial for making split – second decisions. For instance, in a high – speed packaging plant, the CI840 can quickly transmit data from sensors that detect product dimensions or packaging material quality to the control system. The control system can then instantaneously adjust the packaging machinery’s speed, temperature, or pressure settings, ensuring that each product is packaged accurately and efficiently, minimizing production delays and maximizing output.

Resilience is a defining characteristic of the CI840. Built with high – quality components and a rugged construction, it can endure the harsh conditions that are commonplace in industrial settings. Electrical noise, which is often generated by nearby motors, transformers, or other electrical equipment, can interfere with communication signals. However, the CI840 is equipped with advanced noise – filtering technologies that enable it to operate flawlessly in such electrically noisy environments. Vibrations, which are prevalent in manufacturing plants due to the operation of heavy machinery, can also pose a threat to the stability of communication modules. The CI840’s robust construction and shock – absorbing design elements ensure that it remains stable and functional, even in the face of significant vibrations. Temperature fluctuations, which can range from extreme cold in refrigerated warehouses to intense heat in furnaces or ovens, are also no match for the CI840. Its wide operating temperature range allows it to maintain consistent performance, reducing the likelihood of communication failures, minimizing maintenance requirements, and ultimately boosting the overall uptime of the industrial system.

Interoperability lies at the very core of the ABB CI840’s design philosophy. It can seamlessly integrate with a wide range of ABB products, such as the AC 800m controller family, as well as numerous third – party devices that support the Profibus DP – V1 protocol. This extensive compatibility provides unparalleled flexibility in system design, allowing for easy expansion and upgrades. Whether an industrial enterprise is building a new state – of – the – art industrial automation system from the ground up or enhancing an existing legacy system, the CI840 can be effortlessly incorporated into the network. It ensures smooth and harmonious communication between all connected elements, regardless of their manufacturer or origin, making it a versatile and highly sought – after choice for various automation projects.

The ABB CI840 finds extensive and diverse applications across a wide range of industries, delivering significant value and tangible benefits in each. In the chemical industry, within a large – scale DCS setup, the CI840 serves as the vital link between the central control room and the multitude of field devices scattered throughout the plant. It enables operators to monitor critical process parameters in real – time, such as the temperature and pressure within chemical reactors, the flow rate of raw materials and finished products through pipelines, and the composition of chemical mixtures. By ensuring accurate and timely data transfer, the CI840 plays a pivotal role in maintaining the stability of chemical reactions. This, in turn, ensures the production of high – quality chemical products while adhering to strict safety and environmental standards. For example, in a petrochemical plant, the CI840 can transmit data from sensors that monitor the temperature and pressure of cracking furnaces. The control system can then adjust the feed rate of crude oil or the temperature of the furnace to optimize the cracking process, maximizing the yield of valuable petrochemical products and minimizing the production of unwanted by – products.

In the power generation sector, especially in large – scale power plants, the CI840 plays a crucial and indispensable role within a SCADA system. It facilitates seamless communication between the central control center and the various generators, transformers, and other electrical equipment that are distributed across the plant. This enables operators to monitor the performance of the power generation system in real – time, detect potential issues at an early stage, and take corrective actions promptly. In a coal – fired power plant, the CI840 can transmit data from sensors that monitor the temperature and pressure of the boiler, the speed and load of the turbines, and the voltage and current of the generators. The control system can then adjust the fuel supply, the air intake, or the excitation of the generators to optimize the power generation process, ensuring stable and efficient power output. In a wind farm, the CI840 can transmit data from wind turbines regarding power output, blade speed, and system status. This data can be used to perform proactive maintenance on the wind turbines, such as predicting when a component is likely to fail and scheduling maintenance before a breakdown occurs, thereby optimizing energy production and reducing downtime.

- CI801: A more basic communication interface module from ABB, suitable for less complex industrial setups where lower – speed data transfer and fewer features are required compared to the CI840. It may be more cost – effective for small – scale operations that do not demand the high – speed data transfer capabilities or the advanced features of the CI840. However, it still provides reliable communication for basic control functions, such as connecting a few sensors and actuators in a simple manufacturing cell.

- CI840A: An upgraded version of the CI840, which may offer enhanced performance, additional features, or improved compatibility with newer ABB systems and emerging industrial technologies. For example, it could have faster data processing capabilities, allowing it to handle even larger volumes of data in real – time. It may also have enhanced diagnostic functions, enabling quicker identification and resolution of communication issues, further reducing downtime in critical industrial operations.

- CI830: Another communication module in ABB’s lineup, with different communication capabilities and protocol support. It may be tailored to specific industrial applications where the requirements differ from those met by the CI840. For instance, it could be designed to work with a different industrial communication protocol that is more prevalent in a particular industry, such as the CANopen protocol, which is commonly used in automotive manufacturing and some industrial robotics applications.

- CI860: Designed for more specialized communication tasks, perhaps with a focus on high – security or high – reliability applications. It may offer features such as enhanced encryption to protect sensitive data in industries where data security is of utmost importance, such as in the aerospace or defense sectors. It could also have redundant communication channels and advanced self – healing capabilities to ensure continuous operation even in the face of hardware failures or external interference.

- CI820: A module with a different form factor or power consumption characteristics. It may be suitable for space – constrained or energy – sensitive industrial environments where the CI840’s standard design may not be ideal. For example, in a compact control cabinet where space is limited, the CI820’s smaller size could allow for easier installation. In an industrial facility that is aiming to reduce its energy consumption, the CI820’s lower power consumption could make it a more attractive option.

- CI850: This module might be optimized for communication in large – scale industrial networks, with features like increased network node capacity or advanced network management capabilities compared to the CI840. It could be used in sprawling industrial complexes with hundreds or even thousands of field devices, where efficient network management is crucial to ensure smooth data transfer and minimize communication bottlenecks. It may also have advanced routing algorithms to direct data traffic more effectively within the network.

- CI810: With a different set of communication protocol support, it can be used in industrial applications where the CI840’s Profibus DP – V1 focus may not be sufficient. It enables connection to devices that use alternative communication standards, such as the Modbus RTU protocol, which is widely used in industrial automation for connecting sensors, actuators, and other devices. This makes the CI810 a suitable choice for industries or applications that have a mix of devices using different communication protocols and need to integrate them into a unified control system.

Installing the ABB CI840 requires meticulous attention to detail. When mounting it within a control cabinet, it is essential to ensure that the cabinet provides a stable and well – ventilated environment. The module should be securely fastened using the appropriate mounting hardware to prevent any vibrations from affecting its performance. Even minor vibrations can cause intermittent communication issues or damage to the internal components over time. When making electrical connections, it is crucial to follow the wiring diagrams provided in the user manual precisely. Incorrect wiring can lead to electrical short – circuits, damage to the module, or communication failures. Proper grounding is also of utmost importance to protect the module from electrical surges and interference. A well – grounded system can divert excess electrical energy away from the CI840, ensuring its reliable operation. Additionally, during the initial setup, the communication parameters must be configured correctly to ensure seamless integration with other devices in the network. This includes setting the appropriate baud rate, parity, and other communication – related settings to match the requirements of the connected devices.

For long – term operation, regular maintenance of the CI840 is of paramount importance. Periodically, the module should be inspected for any signs of physical damage, such as cracks in the casing, loose connections, or abnormal heat generation. Cracks in the casing can expose the internal components to dust, moisture, or other environmental contaminants, which can lead to premature failure. Loose connections can cause intermittent communication issues or electrical arcing, which can also damage the module. Abnormal heat generation can be a sign of a malfunctioning component within the module, and if left unaddressed, can lead to complete failure. The status indicators on the module should be checked regularly to ensure that it is operating within normal parameters. These indicators can provide valuable information about the module’s communication status, power supply, and overall health. It is also advisable to update the module’s firmware as per ABB’s recommendations. Firmware updates often bring performance enhancements, security patches, and compatibility improvements. For example, a firmware update may improve the module’s data processing speed, enhance its ability to handle complex communication protocols, or fix security vulnerabilities that could be exploited by malicious actors. By keeping the firmware up – to – date, the ABB CI840 can continue to operate at its best throughout its service life, providing reliable and high – performance communication for industrial automation systems.

ABB stands firmly and unwaveringly behind the quality and reliability of the ABB CI840. Backed by a comprehensive warranty, customers can have complete peace of mind knowing that their investment is protected. In case of any issues, ABB’s global support network is readily available. Technical experts can provide remote assistance, using advanced diagnostic tools to help users diagnose and resolve problems quickly. For more complex issues that cannot be resolved remotely, ABB can dispatch on – site support teams. These teams are composed of highly trained and experienced technicians who can quickly identify and fix the problem, minimizing downtime. Additionally, ABB offers a wealth of documentation, including detailed user manuals, installation guides, and troubleshooting resources. The user manuals provide step – by – step instructions on how to install, configure, and operate the CI840, making it easy for even novice users to get started. The installation guides offer detailed diagrams and instructions on how to properly mount and wire the module, ensuring a safe and correct installation. The troubleshooting resources are invaluable for users when they encounter problems, as they provide a comprehensive guide to identifying and resolving common issues. This commitment to long – term reliability and customer satisfaction makes the ABB CI840 a trusted and preferred choice for industrial communication applications.

For more information, please click below to learn more:

Reviews

There are no reviews yet.