Description

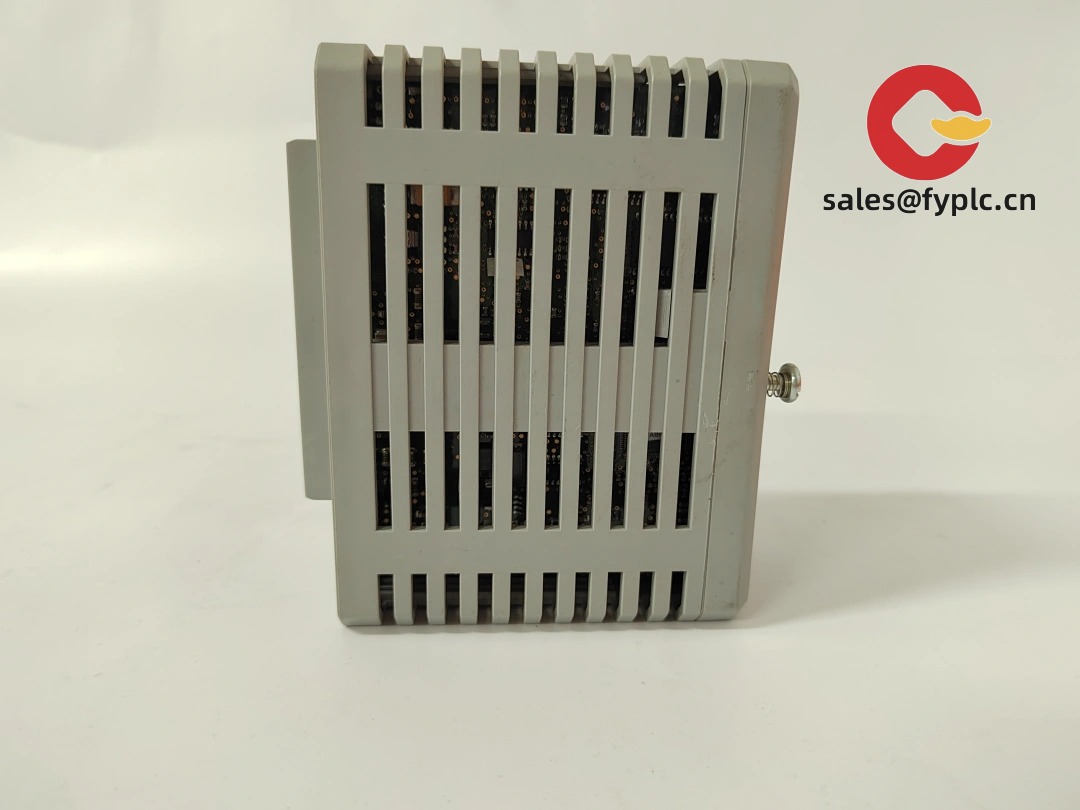

ABB CI854A-eA 3BSE030221R2 – PROFIBUS-DP interface module for AC 800M controllers

The ABB CI854A-eA (P/N 3BSE030221R2) is a dual-channel PROFIBUS-DP interface for the AC 800M platform. From my experience, it’s the straightforward way to connect the controller to drives, remote I/O, and field devices on DP-V1 networks without extra gateways. The “eA” hardware revision typically keeps the same functionality as the classic CI854A while bringing updated electronics and long-term availability—handy for lifecycle-managed plants.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Dual PROFIBUS-DP channels – Two independent RS‑485 DP segments on one module for segregated networks or increased device count.

- DP‑V1 support – Cyclic I/O plus acyclic parameterization and diagnostics; convenient for drive commissioning and device health checks.

- 12 Mbit/s data rate – Auto‑adaptable to common PROFIBUS speeds; works well in both brownfield and new builds.

- AC 800M CEX‑bus – Powered and managed by the controller, no external power supply on the module level in most cases.

- “eA” hardware revision – Typically a drop‑in successor to CI854A with improved lifecycle; check firmware compatibility before mixing revisions.

- Robust diagnostics – Front LEDs and DP‑V1 alarms make it easier to pinpoint wiring faults, segment terminations, or device issues.

- Flexible device integration – Works with standard GSD files; commonly used with remote I/O (e.g., ET200‑class), VFDs, analyzers, and weigh scales.

Technical Specifications

| Brand / Model | ABB CI854A-eA, 3BSE030221R2 |

| HS Code | 8517.62.00 (Data communication apparatus) |

| Main Function | PROFIBUS‑DP interface (DP‑V1) for AC 800M controllers |

| Signal I/O Types | Fieldbus data (no direct analog/digital channels) |

| Communication Interfaces | 2 × PROFIBUS‑DP (RS‑485), up to 12 Mbit/s, DP‑V1 master; device diagnostics via acyclic services |

| Power Requirements | Powered from AC 800M CEX‑bus; no separate module supply typically required |

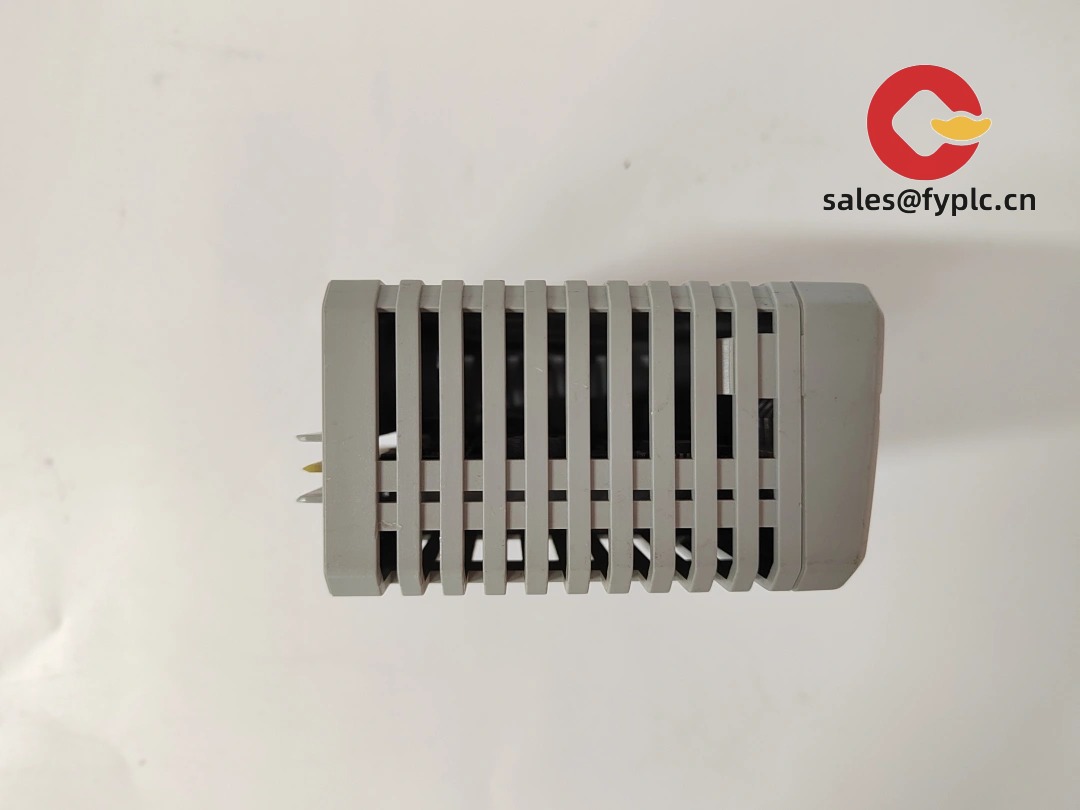

| Installation Method | Mounts on AC 800M CEX‑bus base/DIN rail; front connectors for PROFIBUS cabling |

| Operating Temperature | 0 to +55 °C (typical for AC 800M modules) |

| Dimensions & Weight | Standard AC 800M CEX module form factor (contact us if you need the outline drawing) |

| Configuration | Control Builder M Professional; device GSD import for DP nodes |

Application Fields

Plants that standardize on PROFIBUS still lean on this module for controller‑to‑field integration. Typical deployments include:

- Drives and motion: Linking AC/DC drives and servo packs over DP‑V1 for both cyclic speed/torque control and acyclic parameter access.

- Remote I/O: Connecting ET200‑class remote stations in process skids or MCCs where PROFIBUS wiring already exists.

- Process instruments: Scales, analyzers, and specialty devices with DP interfaces in chemical, F&B, and metals.

- Modernizations: Drop‑in replacement where legacy fieldbus needs to coexist with newer controllers.

Advantages & Value

- Reliability – Mature DP stack with stable behavior; you might notice fewer nuisance faults once cabling and termination are correct.

- Compatibility – Works with standard GSDs; in many cases, devices from multiple vendors can coexist on the same segment.

- Cost control – Two channels reduce the need for extra interface cards; simplifies spares and panel real estate.

- Lifecycle confidence – The eA revision seems to be positioned for long-term availability and service continuity.

- Support – Clear diagnostics, and the configuration path through Control Builder M keeps engineering time reasonable.

Installation & Maintenance

- Cabinet & ventilation – Install on a DIN rail within an AC 800M rack/cabinet that meets industrial ventilation and temperature specs. Avoid heat sources right beneath the module.

- Wiring practices – Use PROFIBUS type‑A shielded twisted pair; keep consistent impedance; ensure shield continuity and proper grounding at designated points.

- Termination – Terminate each DP segment at both physical ends. If you use D‑sub connectors with integrated terminators, verify the switch position during commissioning.

- Segment length – Respect the PROFIBUS length vs. baud‑rate rules; repeaters can extend segments if needed.

- Firmware compatibility – The eA variant typically requires later AC 800M firmware. Check your controller’s software version matrix before swapping modules.

- Routine checks – Inspect connectors for looseness or oxidation annually; review DP diagnostics for rising error counters; back up project files after any GSD updates.

Quality & Certifications

- Conformity typically includes CE and RoHS; many installations also rely on UL recognition for industrial control equipment.

- Manufacturer’s warranty practices apply; sales warranty provided here is 365 days.

Supporting Components (recommended)

- PROFIBUS type‑A cable and 9‑pin D‑sub connectors (with switchable termination).

- DIN‑rail PROFIBUS repeaters/isolators for long runs or noisy sections.

- Surge protection for fieldbus lines in outdoor or high‑exposure areas.

- Labeling and test plugs to simplify maintenance and reduce downtime.

One thing I appreciate is how painless migration tends to be. A systems integrator told us they swapped a legacy CI854A to CI854A‑eA in a rolling mill with only a brief stop—same configuration loaded, devices came online, and the DP diagnostics immediately helped spot a single loose termination. That’s the kind of low‑drama upgrade plants usually want.

Reviews

There are no reviews yet.