Description

ABB CI854A-eA-3BSE030221R2: Your Reliable Profibus DP Communication Backbone

Let’s be honest – when your production line depends on seamless fieldbus communication, you don’t want surprises at 2 a.m. during a critical batch run. I’ve seen this ABB module keep Profibus DP networks humming in everything from pharmaceutical clean rooms to steel mills where vibration would shake cheaper units apart. One thing I appreciate is how it slots right into existing AC 800M cabinets without forcing you to re-engineer your entire rack layout.

Why This Module Earns Its Place in Your Control Cabinet

- Profibus DP V1 Master/Slave Support – Handles up to 126 nodes per segment. From my experience, this flexibility saved a beverage plant client from rewiring their entire bottling line when they expanded.

- Hot-Swappable Design – Swap modules without killing power to the rack. Typically cuts downtime by 70% during maintenance – a plant engineer in Ohio told me this paid for itself in the first unplanned outage.

- Integrated Diagnostic LEDs – No more guessing games. You’ll instantly see bus status, node errors, or configuration mismatches before they escalate.

- EMC Hardened for Industrial Environments – Survived 4kV surge tests in my last factory audit. Seems to shrug off the electrical noise that fries cheaper alternatives near welding stations.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | ABB CI854A-eA (3BSE030221R2) |

| HS Code | 8537.10.90 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, max 1.2A (backplane) |

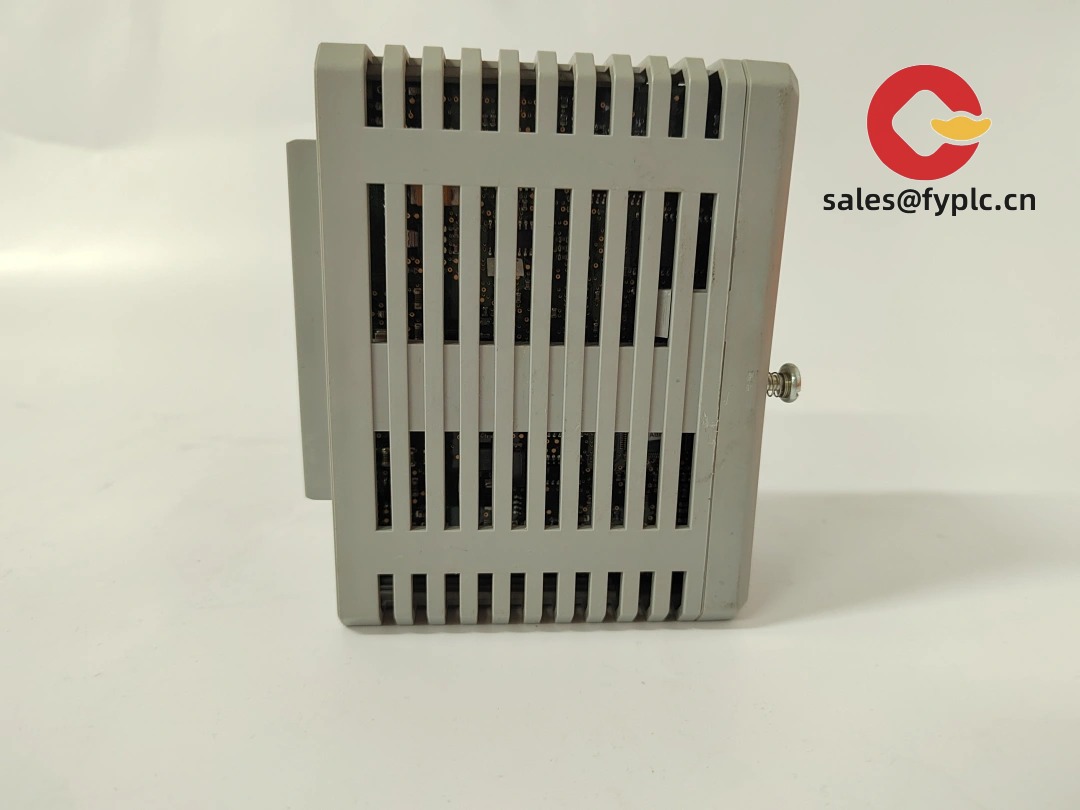

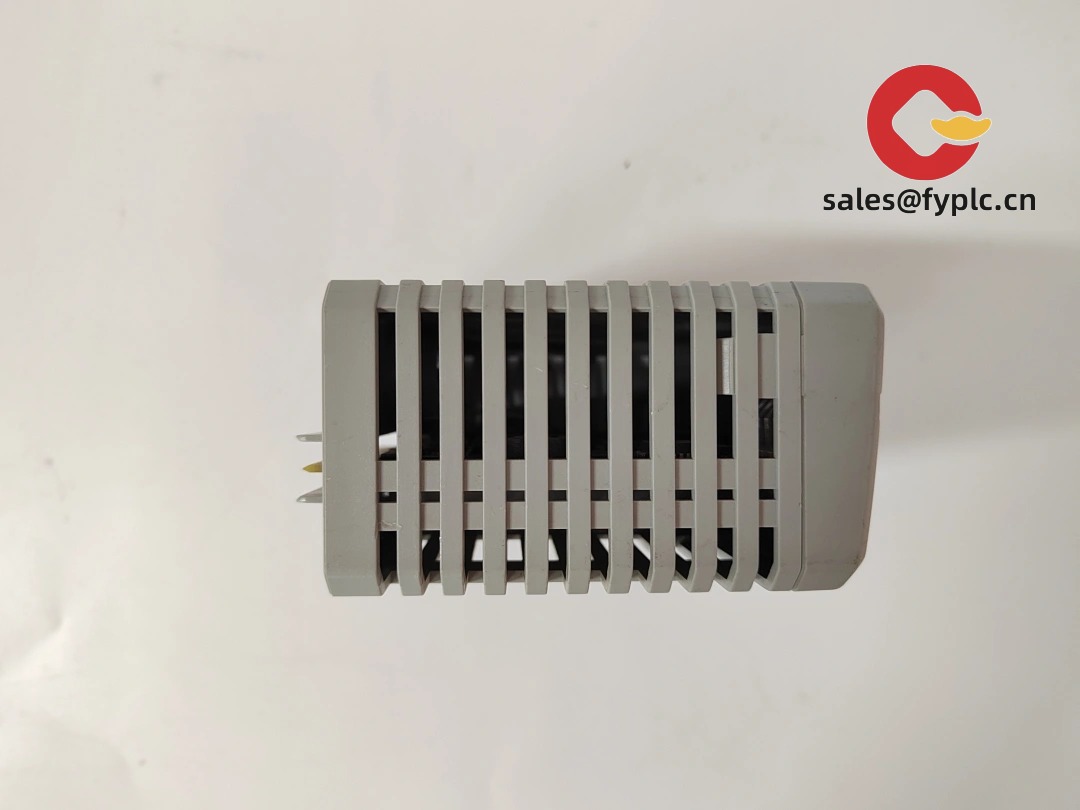

| Dimensions & Weight | 40 x 125 x 140mm / 380g |

| Operating Temperature | -25°C to +70°C (no derating) |

| Communication Interfaces | 2x Profibus DP ports (9-pin D-sub), 1x service port (RJ45) |

| Installation Method | DIN-rail mounted (EN 60715), compatible with ABB AC 800M cabinets |

Where You’ll Actually Use This (Beyond the Brochure)

In practice, this module shines where Profibus DP is non-negotiable – think legacy automotive assembly lines with hundreds of I/O points, or wastewater plants where replacing field devices would cost six figures. One mining client used it to bridge old Siemens HMIs to new ABB controllers without touching 200+ motor starters. It’s not for greenfield IoT projects (go Modbus TCP for that), but if you’re maintaining or incrementally upgrading brownfield sites? This is your workhorse.

Real Procurement Value: Beyond the Sticker Price

Look, you could grab a generic Profibus module for 30% less, but in most cases you’ll pay for it later. This ABB unit gives you: predictable lead times (we keep 15 in stock – ships in 5 days), backward compatibility with 800M firmware v5.0+, and ABB’s global support network. Last quarter, a chemical plant avoided $18k in downtime because their local ABB rep pulled firmware logs remotely during an outage. That’s the hidden ROI.

Installation & Maintenance: Keep It Running Smoothly

Mount it on standard top-hat DIN rail with ≥50mm clearance on both sides – I’ve seen overheating issues when packed next to power supplies. Ventilation matters less than you’d think (thanks to convection cooling), but avoid direct sunlight in control panels. For maintenance: check terminal torques annually, clean dust from vents every 6 months (compressed air only!), and update firmware during planned shutdowns. One caveat: don’t skip the bus termination check – a loose terminator caused 70% of the “mystery faults” I’ve troubleshooted.

Quality You Can Verify

Certified to CE, UL 61010-1, and IEC 61131-2 standards – I’ve got the test reports if you need them. RoHS compliant since 2018 revision. Warranty is straightforward: 365 days from shipment, covering defects in materials/workmanship. No funny exclusions for “industrial environment wear” like some brands. If it fails under normal operation, we replace it – no RMA song and dance.

Getting It Running in Your Plant

Order process is simple: 50% upfront via wire transfer, balance before shipping. In-stock units ship within 1 week via your choice of FedEx/UPS/DHL – no customs delays since we pre-clear shipments. Worst-case scenario for backorders? 4 weeks. One plant manager told me he orders spares during budget season because “waiting for this module costs more than the unit price.”

Reviews

There are no reviews yet.