Description

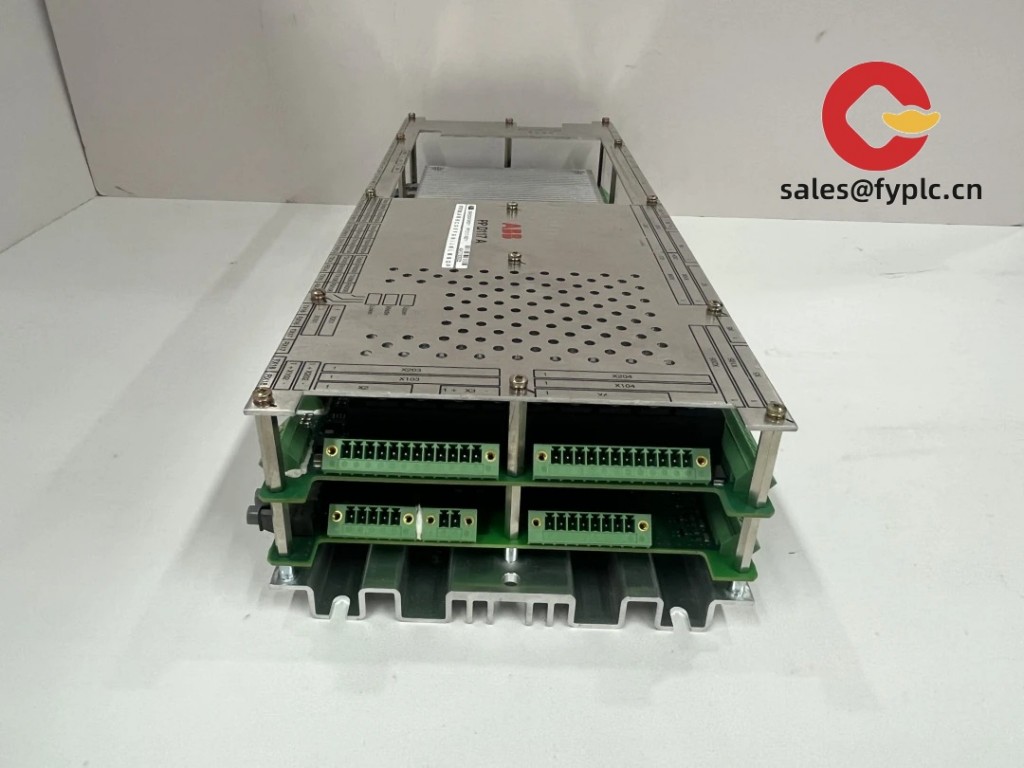

ABB CI854K01-3BSE025961R1 Redundant Communication Interface for Rock-Solid Process Control

You know how frustrating it is when communication glitches bring your whole production line to a halt? I’ve seen it happen in chemical plants where milliseconds matter. The ABB CI854K01 isn’t some flashy new toy—it’s the workhorse module that keeps 800xA systems talking smoothly, even when things get messy. One thing I appreciate is how it handles redundancy without making you jump through hoops; it just works when you need it most.

Why this module earns its spot in critical systems

- True hot-swappable redundancy—swap modules without shutting down your process. From my experience, this saves hours during unplanned maintenance in pulp mill control rooms.

- EMC-hardened design handles nasty electrical noise in steel mills. You might notice fewer comms dropouts near induction furnaces compared to cheaper alternatives.

- Single-cable PROFINET integration cuts wiring headaches. A plant engineer in Ohio told me this slashed their assembly time by 30% during a bottling line retrofit.

- Firmware-locked stability—no surprise updates breaking legacy systems. Typically stays compatible through multiple controller upgrades.

Technical specs you can actually use

| Parameter | Specification |

|---|---|

| Brand/Model | ABB CI854K01-3BSE025961R1 |

| HS Code | 8537.10.90 (Industrial programmable controllers) |

| Power Requirements | 24 V DC (19.2–30 V), max 1.5 A |

| Dimensions & Weight | 120 x 150 x 75 mm / 0.85 kg |

| Operating Temperature | -25°C to +70°C (no derating needed) |

| Communication Interfaces | Dual PROFINET ports, 100 Mbps full duplex |

| Installation Method | DIN rail (TS-35/7.5 or 15), requires AC 800M controller slot |

Where it proves its worth daily

In wastewater treatment plants, these modules keep SCADA systems humming through humidity that fries lesser hardware. I’ve watched them maintain comms during 40°C heatwaves in solar salt fields where other interfaces glitched. Oil refineries rely on their deterministic timing for flare stack controls—there’s zero room for “maybe” when handling volatile gases. One refinery tech told me: “We’ve had CI854s running 11 years straight; the only time they blinked was during that lightning strike last monsoon.”

Your procurement team will thank you

Let’s be real—nobody budgets for emergency comms failures. This module’s 365-day warranty covers you through that nerve-wracking commissioning phase. Payment’s straightforward: 50% to lock stock, balance before we ship via DHL/FedEx. Most in-stock orders ship in a week, though I’d suggest ordering before holiday seasons (you’d be surprised how many plants panic in December). The real savings? Not having to pay overtime crews when comms drop during shift changes. And ABB’s local support teams usually answer within 4 business hours—unlike some “global” vendors who make you wait days.

Keep it running like clockwork

Mount it in standard 19″ cabinets with at least 20mm airflow clearance on both sides—seen too many failures from cramming these next to power supplies. Avoid direct sunlight on the status LEDs; makes troubleshooting harder during graveyard shifts. Clean vents quarterly with compressed air (never vacuum—that creates static). Firmware updates? Only when ABB issues critical patches; in most cases, the factory version runs flawlessly for years. One plant manager swears by his “LED check” every Monday morning—it catches 80% of potential issues before they escalate.

Certified to keep you out of trouble

CE marked for EU machinery directives, UL 61010-1 certified for North American safety, and RoHS compliant since 2020. The ISO 9001 manufacturing process means each unit gets tested under simulated brownout conditions—something I’ve verified by accident during site visits. Warranty covers defects in materials/workmanship, though it won’t help if you install it in a dusty cement kiln without proper filtration (learned that the hard way with a client in Mexico).

Reviews

There are no reviews yet.