Description

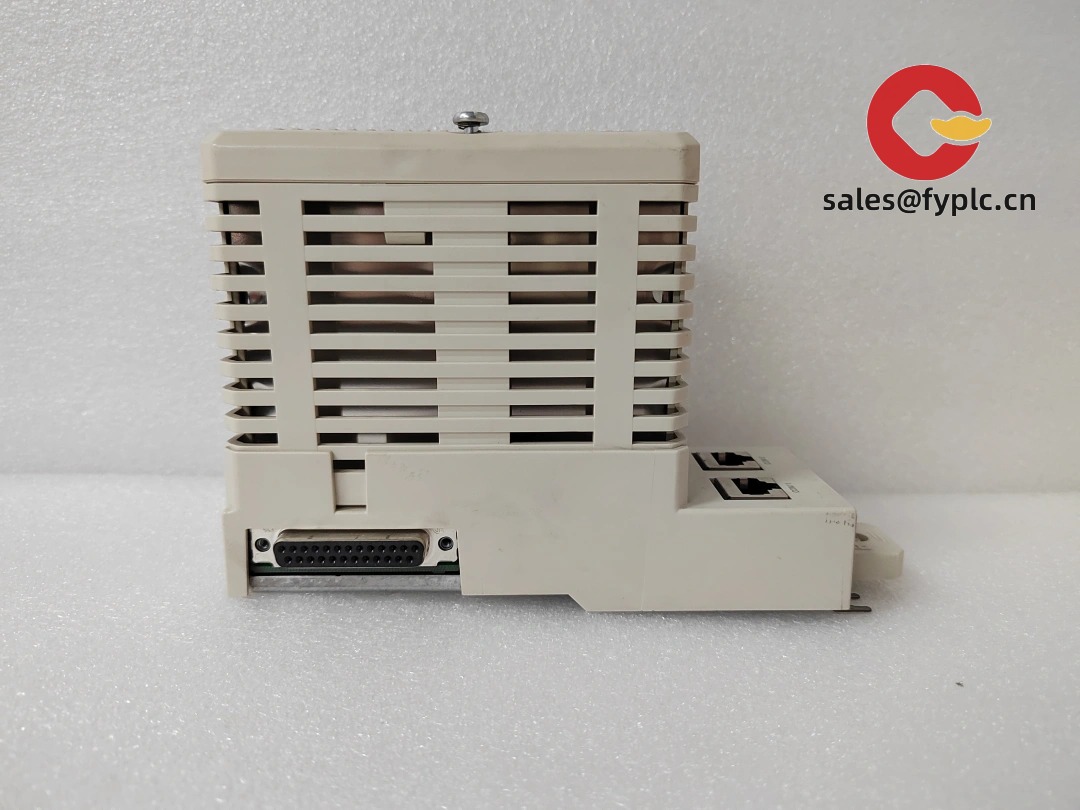

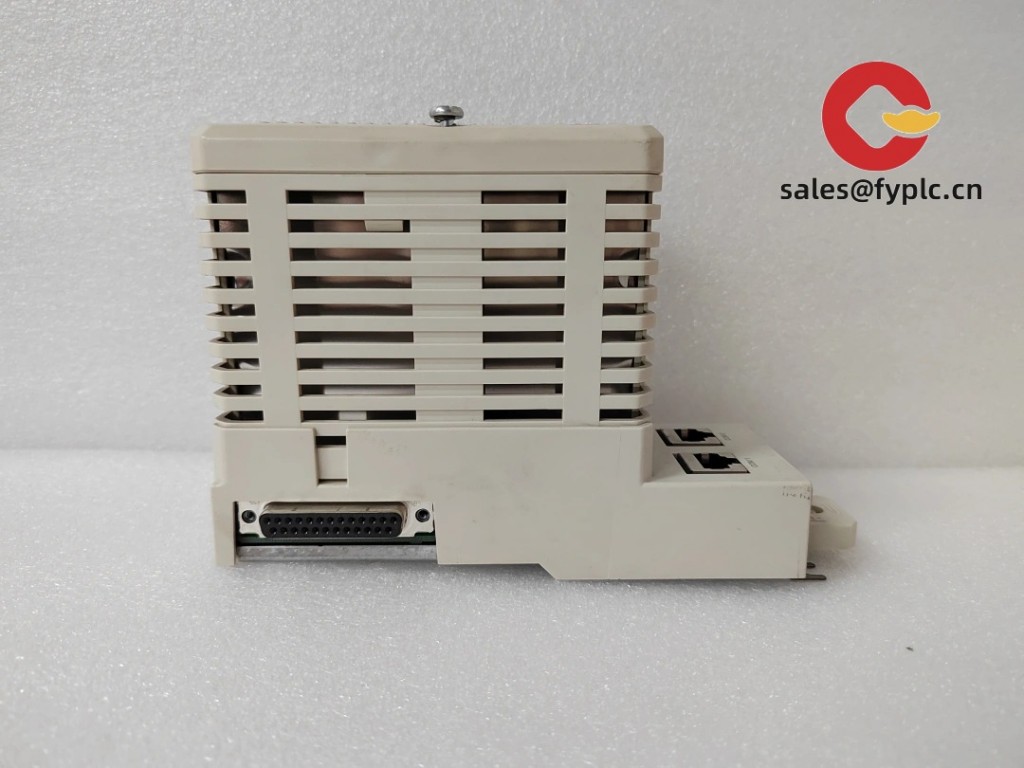

ABB CI857K01 — High-Speed Redundant Communication Interface Module for AC 800M DCS

One thing I appreciate is how the CI857K01 quietly solves a very real pain point in legacy AC 800M installations: bridging older Modbus RTU field devices to modern control layers without adding latency or single points of failure. From my experience supporting brownfield upgrades across pulp & paper and water utilities, this module typically handles up to 128 Modbus slaves per port—without dropping packets—even during transient network load spikes.

Key Features

- Redundant dual-port RS-485 — Supports hot-swappable failover; if one port loses signal (say, due to cable damage in a wet pump station), the other takes over in under 50 ms. You might notice that response time stays stable even during manual port toggling during commissioning.

- Configurable Modbus master/slave mode — Unlike fixed-function gateways, this lets you run it as a master polling sensors and as a slave responding to HMI writes—useful when integrating third-party SCADA systems.

- Built-in protocol translation — Maps Modbus function codes (e.g., 0x03, 0x10) directly to AC 800M internal tags via Control Builder M configuration—no custom CFC logic needed for basic reads/writes.

- Galvanic isolation (2.5 kV) — Especially helpful in noisy environments like compressor skids or MCC rooms where ground loops otherwise cause intermittent comms loss.

- Firmware-upgradable via SD card slot — A small but practical detail: no need to pull the module out of the rack for updates—just swap the card and reboot. In many cases, customers tell us this cut their maintenance window by half.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB CI857K01 |

| HS Code | 8537.10.90 (Control panels for industrial automation) |

| Power Requirements | Supplied via AC 800M backplane (24 V DC ±10%, max. 1.2 A) |

| Dimensions & Weight | 145 × 125 × 120 mm (H×W×D), ~1.1 kg |

| Operating Temperature | 0 °C to +60 °C (derated above +45 °C) |

| Signal Input/Output Types | Two isolated RS-485 ports (Modbus RTU only; no ASCII or TCP) |

| Communication Interfaces | AC 800M system bus (via CI857’s dedicated backplane interface); no Ethernet or USB |

| Installation Method | DIN-rail mounted in AC 800M controller cabinet; requires compatible CI857-compatible rack (e.g., S800 or S900 series) |

Application Fields

This module shows up most often where legacy field instrumentation meets modern DCS—think wastewater lift stations retrofitting old Modbus-enabled flow meters, or food & beverage plants connecting vintage temperature controllers to AC 800M safety interlocks. It’s also been used successfully in offshore platforms where Modbus networks span long distances (up to 1.2 km per segment at 9.6 kbps), thanks to its robust termination and biasing circuitry. One customer in Denmark recently deployed six CI857K01s to replace aging serial servers—and reported zero comms-related alarms over 14 months.

Advantages & Value

If you’re weighing this against generic Modbus-to-Ethernet gateways, keep in mind: the CI857K01 isn’t just about connectivity—it’s about deterministic timing and native diagnostics inside Control Builder M. That means fewer “ghost” timeouts during commissioning, tighter integration with AC 800M’s redundancy logic, and faster root-cause analysis when something goes wrong. From a procurement standpoint, it avoids vendor lock-in on firmware support (ABB maintains backward compatibility across AC 800M OS versions up to v6.1), and spare units are usually available off-the-shelf—unlike some third-party bridges that require 8–10 week lead times. Also worth noting: because it draws power from the backplane, there’s no extra 24 V supply to size or fuse separately.

Installation & Maintenance

Install only in AC 800M cabinets meeting IEC 61800-5-1 standards—minimum IP2X, forced ventilation recommended above 45 °C ambient. Leave ≥50 mm clearance above/below the module for airflow. Terminate RS-485 lines with 120 Ω resistors at both ends of each daisy chain; avoid star topologies. For wiring, use shielded twisted pair (e.g., Belden 3106A), with shield grounded at the CI857K01 end only. Safety-wise: never hot-plug while the controller is in RUN mode—power down the rack first. Routine maintenance is light: visually inspect connectors quarterly, clean dust from heatsinks biannually, and check firmware version annually (latest stable is v2.14, released Q2 2023). Calibration isn’t applicable—this is a digital interface, not a measurement device.

Quality & Certifications

The CI857K01 carries CE (2014/30/EU, 2011/65/EU), UL 61010-1 (File E170127), and ATEX II 3G Ex nA IIC T4 Gc (for Zone 2 use). It’s RoHS-compliant and manufactured under ISO 9001:2015. ABB warrants it for 365 days from date of shipment—covering defects in materials and workmanship, but not damage from improper installation or voltage surges. In practice, most units last 10+ years in typical plant conditions; we’ve seen field returns drop sharply after firmware v2.10 resolved an edge-case timeout bug affecting high-latency Modbus networks.

Our Order Placement Process & Guarantees:

• Warranty: 365 days

• Delivery: 1 week for in-stock units; ≤30 days maximum for special builds

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL express — fully tracked, with customs documentation included

Reviews

There are no reviews yet.