Description

ABB CM772F (3BDH000368R0001) — High-Integrity Motor Protection Relay for Critical Industrial Drives

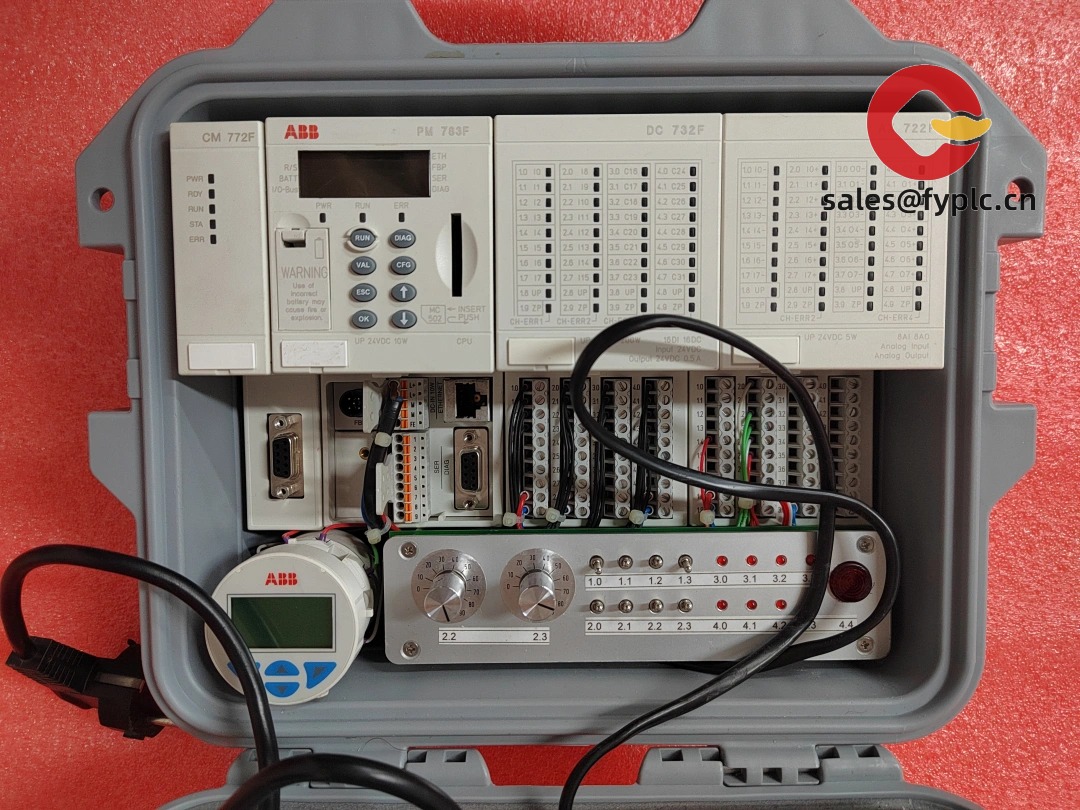

One thing I appreciate is how the CM772F bridges the gap between basic overload relays and full-fledged motor management systems—without overcomplicating commissioning. It’s not a PLC, but it behaves like one when it comes to diagnostics: thermal memory, stall detection, phase loss, and even ground fault monitoring all run in parallel, with real-time status visible via its local LED interface or Modbus RTU. A plant engineer in Rotterdam told me they swapped out three legacy relays on a wastewater pump station—and cut nuisance trips by 70% after enabling the built-in start-up inhibition delay. That kind of reliability isn’t accidental.

Key Features

- Adaptive thermal modeling: Tracks motor heating/cooling curves dynamically—not just fixed time delays—so it handles frequent starts/stops without false tripping.

- Integrated ground fault detection (up to 5 A): Uses residual current measurement (no external CTs needed), which saves panel space and wiring labor—especially useful in compact MCC buckets.

- Modbus RTU over RS-485 (standard): Reads real-time amps, thermal %, trip history, and relay status directly into SCADA—no gateway required. You might notice that many users skip the optional ABB PCM module entirely because the native protocol works reliably up to 1.2 km.

- Configurable logic outputs (3 x Form C): Lets you assign independent actions—e.g., “Output 1 = alarm only”, “Output 2 = trip + latching”, “Output 3 = pre-alarm at 85% thermal”—all set via DIP switches or software.

- UL Listed Class 10 & 20 overload response: Certified for both standard and high-inertia loads, meaning it fits everything from conveyor belts to large centrifugal compressors without recalculating settings.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB CM772F (3BDH000368R0001) |

| HS Code | 8536.20 — Electrical relays, for a voltage ≤ 1 kV |

| Power Requirements | 24–240 V AC/DC ±15%, 4.5 VA max (self-powered from control supply) |

| Dimensions & Weight | 90 × 130 × 105 mm (W×H×D); ~680 g |

| Operating Temperature | −25 °C to +70 °C (derated above 55 °C) |

| Signal Input Types | Three-phase current inputs (via integrated CTs, 0.5–10 A range), optional external PT input for voltage supervision |

| Signal Output Types | 3 × Form C relay outputs (6 A @ 250 V AC resistive); configurable as alarm/trip/latching |

| Communication Interfaces | RS-485 Modbus RTU (slave only), 9600–115200 bps, 2-wire |

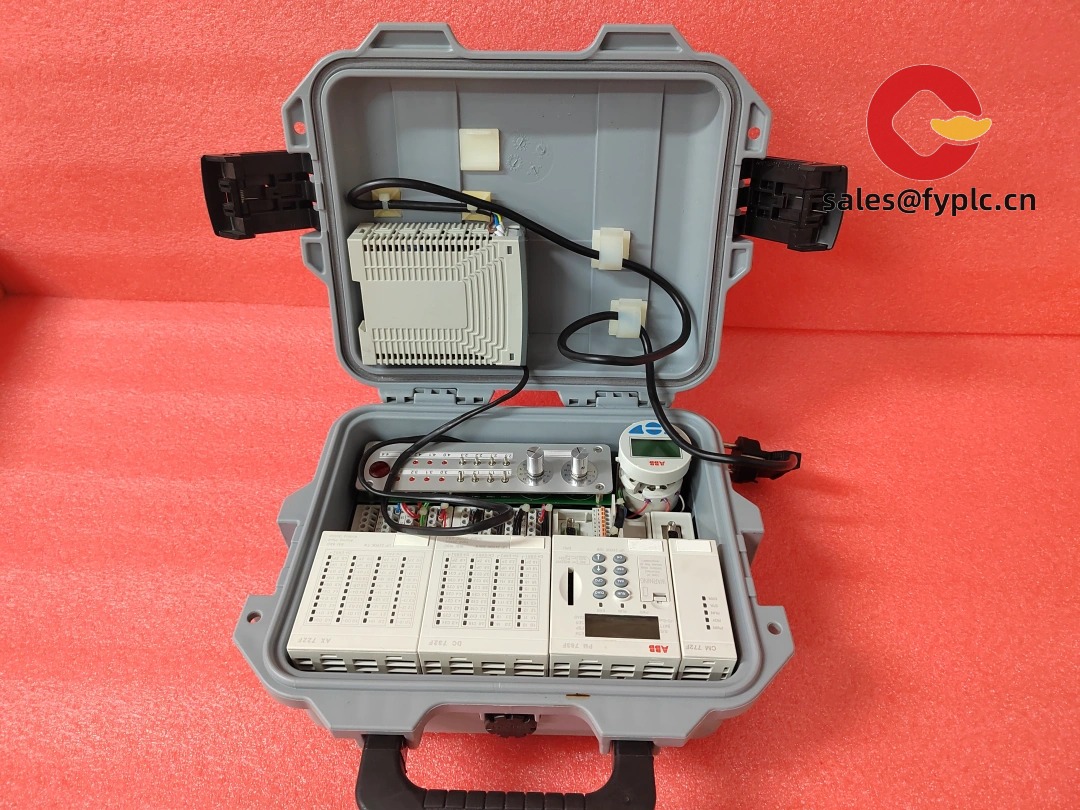

| Installation Method | DIN rail (TS35/7.5 or TS35/15), vertical mounting preferred; IP20 enclosure |

Application Fields

This relay shows up where downtime costs more than the device itself—think HVAC chillers in pharmaceutical cleanrooms, feedwater pumps in district heating networks, or extruder drives in polymer plants. From my experience, it’s especially common in retrofits: engineers keep the existing motor contactor and fuse setup, then drop in the CM772F to add digital protection and remote visibility without rewiring the entire starter. It also handles motors fed from VFDs well—provided the output is filtered (it tolerates up to 5% THD on current waveform).

Advantages & Value

If you’re evaluating this for procurement, here’s what typically matters: First, compatibility. It integrates cleanly with ABB’s ACS880 and older ACS800 drives—but also works fine with Siemens, Danfoss, or Yaskawa VFDs via Modbus, so no vendor lock-in. Second, lifecycle cost: the 3-year warranty (standard) and field-replaceable CT modules mean fewer spares inventory lines. Third, support responsiveness—ABB’s regional service centers usually dispatch firmware updates or configuration files within 24 hours if something’s misbehaving in commissioning. One customer in Sweden reported getting a custom logic configuration file emailed same-day after describing their pump staging sequence over the phone.

Installation & Maintenance

Mount it in a well-ventilated cabinet—minimum 50 mm clearance above/below—and avoid locations near heat sources like power resistors or busbars. Wiring should follow IEC 60204-1: use shielded twisted pair for RS-485, and terminate shields at one end only (relay side). For safety, always isolate motor power before accessing terminals—even though the unit runs off low-voltage control supply, current inputs remain live during operation. Routine maintenance is minimal: visually inspect terminals annually for corrosion (especially in humid or coastal environments), wipe the front lens with isopropyl alcohol if condensation builds up, and check Modbus polling stability every 6 months. Firmware updates are rare (last major revision was v3.2 in early 2023), but when needed, they’re loaded via USB-to-RS485 adapter and ABB’s free PCM software.

Quality & Certifications

The CM772F carries UL 508, CE (EN 61000-6-2/6-4, EN 61000-4-2/3/4/5/6), RoHS 2011/65/EU, and ATEX II 3G Ex nA IIC T4 Gc (for non-hazardous zone use near classified areas). It’s manufactured under ISO 9001:2015 and ISO 14001:2015 at ABB’s facility in Ludvika, Sweden. Warranty is 365 days from shipment date—no registration required. In practice, most field failures (which are uncommon) involve wiring errors or voltage surges, not component defects.

Our Order Placement Process & Guarantees:

• Warranty: Full 365-day coverage

• Delivery: 1 week if in stock (we keep strategic buffer stock in EU warehouses); ≤30 days maximum for special-order batches

• Payment: 50% advance, balance before dispatch

• Shipping: Fedex, UPS, or DHL Express—fully trackable, with customs documentation handled

Reviews

There are no reviews yet.