Description

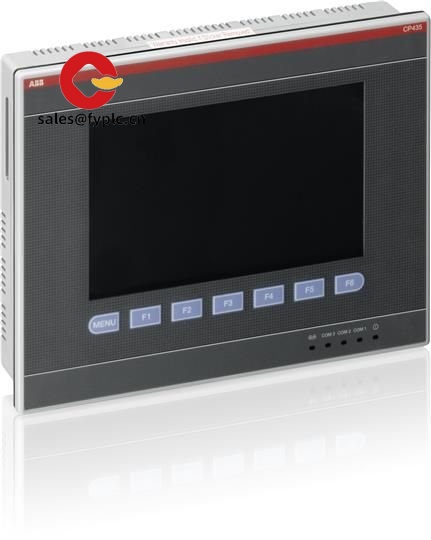

ABB CP435T (1SBP260193R1001) – Compact 3.5-inch HMI for reliable machine operator control

The ABB CP435T is a compact operator panel in the CP400 family, designed for straightforward, dependable human–machine interface tasks on OEM equipment and small to mid-size machines. It typically pairs with ABB AC500 series PLCs or any controller that speaks Modbus RTU. One thing I appreciate is how it fits into tight doors while still giving you a clear, responsive 3.5-inch touch display for setpoints, alarms, and diagnostics. If you’re replacing an older CP400 panel, the model code 1SBP260193R1001 is the exact ordering reference most maintenance teams look for.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 3.5-inch TFT touchscreen (QVGA) – A practical 320×240 display for clear process pages without taking much cabinet space.

- 24 VDC power – Standard industrial supply, typically low power consumption for fan-less operation.

- Serial connectivity for PLCs – RS-232/RS-485 support with Modbus RTU Master/Slave in many cases, ideal for brownfield machines.

- USB device port – Convenient project download and backups without opening up programming laptops to serial drivers.

- Rugged front rating – IP65 (front) when properly panel-mounted; suited to dusty or splash-prone areas.

- Engineering tool compatibility – Typically engineered with ABB’s CP400/Panel Builder environment, which includes a broad driver library.

- Functional pages – Alarms, recipes, user levels, and basic trending for day-to-day operations.

Technical Specifications

| Brand / Model | ABB CP435T – Order code 1SBP260193R1001 (CP400 series HMI) |

| HS Code | 8537.10 (Boards/panels for electric control) |

| Display | 3.5-inch TFT color, resistive touch; 320 × 240 pixels (QVGA) |

| Power Requirements | 24 VDC; typically <10 W |

| Dimensions & Weight | Front approx. 136 × 102 × 36 mm; panel cut-out approx. 119 × 93 mm; approx. 0.35 kg |

| Operating Temperature | 0 to +50 °C (storage typically −20 to +60 °C) |

| Signal I/O Types | No onboard discrete/analog I/O (HMI only) |

| Communication Interfaces | Serial port configurable for RS-232/RS-485; USB device port for project download; Modbus RTU supported in many cases |

| Ingress Protection | IP65 (front) when panel-mounted with gasket; rear typically IP20 |

| Installation Method | Panel mounting with clips; 24 VDC terminals; front sealing gasket |

| Engineering Software | Typically engineered with ABB CP400/Panel Builder environment |

Application Fields

From my experience, the CP435T is a good fit for:

- OEM packaging and labeling machines where space is tight but operators still need clear status and alarm pages.

- Pump skids, compressors, and HVAC sub-panels using Modbus RTU over RS-485.

- Small presses, dosing/dispensing systems, and food & beverage auxiliaries with basic recipe handling.

- Retrofits replacing legacy CP400 panels to avoid program rework and re-cutting cabinet doors.

A packaging OEM told us it “slotted straight into the old cut-out and was talking to the AC500 within the hour,” which seems to be the typical experience when migrating within the CP400 family.

Advantages & Value for Procurement

- Proven reliability – CP400 panels are widely used; failures are rare when powered correctly and kept within temp limits.

- Compatibility – Broad protocol support (not just ABB PLCs), so spares can serve multiple lines in many cases.

- Cost control – Compact size and standard 24 VDC reduce installation cost; re-using existing cut-outs saves labor.

- Support & lifecycle – Stable firmware and tooling; we assist with configuration transfers and project backups when needed.

Installation & Maintenance

- Panel mounting – Follow the recommended cut-out; fit the gasket evenly to maintain IP65. Avoid panel distortion.

- Environment – Keep within 0…50 °C; provide cabinet ventilation. Avoid direct washdown on the rear and excessive vibration.

- Wiring – Use a clean 24 VDC supply with protective earth. Separate HMI power from inductive loads; use shielded cables for RS-485.

- Safety – Power down before connecting USB or serial leads. Observe ESD care when handling the unit.

- Routine care – Wipe the screen with a soft, non-abrasive cloth. Periodically check terminal tightness and back up the HMI project.

- Firmware/tooling – Keep the engineering software and panel firmware aligned; update during planned downtime only.

Quality & Certifications

ABB HMIs in this class typically carry CE and cULus markings and comply with RoHS. Documentation for the CP400 family indicates IP65 front protection and industrial EMC compliance when installed as specified. Warranty coverage from us is 365 days.

Recommended Accessories (optional)

- 24 VDC DIN-rail power supply (e.g., ABB CP-A series) sized with margin for inrush and panel loads.

- Shielded RS-485 cable and termination resistors for longer runs or noisy environments.

- USB programming cable for project download and backups.

- Panel protective film if frequent cleaning or chemical exposure is expected.

Note: Details above reflect the CP400 family characteristics and the CP435T model pattern. If you need us to verify a specific firmware/protocol detail against your PLC and software version, share the controller model and current project files—we’ll double-check compatibility before shipment.

Reviews

There are no reviews yet.