Description

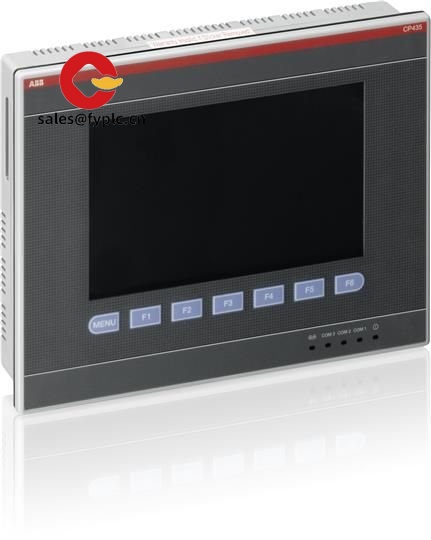

ABB CP435T-ETH – Compact Ethernet Touch Operator Panel for PLC Machines

The ABB CP435T-ETH is a compact HMI from the CP400 family aimed at straightforward, reliable operator control in small-to-mid size machines. From my experience, it’s a solid choice when you want a simple touch interface with native Ethernet for fast PLC connectivity—without overcomplicating the panel design. You might notice that it slots neatly into OEM builds where 24 VDC power, panel mount, and quick commissioning are standard expectations.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express: FedEx, UPS, DHL

Key Features

- Ethernet-enabled (RJ45, 10/100 Mbps): Typically used for fast PLC links such as Modbus/TCP and easy integration into plant networks.

- TFT touch interface: A responsive color touchscreen for operators; ideal for status, alarms, and recipe handling.

- 24 VDC supply: Standard machine-panel power; usually stable with low inrush and easy to fuse.

- Serial connectivity (common on CP400): In many cases, RS-232/RS-485 ports are available for legacy PLCs or barcode devices.

- Panel mounting with IP65 front (when properly installed): Suitable for most industrial cabinets with gasket and clip fastening.

- Data/alarm functions: Trend, alarm banners, and basic data logging are typically supported for machine diagnostics.

- Good ecosystem fit: Plays nicely with ABB PLCs (e.g., AC500 series) and common third-party PLCs via standard protocols.

Technical Specifications

| Brand / Model | ABB CP435T-ETH |

| HS Code | 8537.10 (boards, panels, consoles for electric control ≤ 1000 V) |

| Power Requirements | 24 VDC nominal (typical HMI range 20–30 VDC) |

| Operating Temperature | Typically 0 to +50 °C (non-condensing) |

| Signal Input/Output Types | Touchscreen input; no onboard discrete/analog I/O—communication-based HMI |

| Communication Interfaces | Ethernet (RJ45 10/100); RS-232/RS-485 commonly available on CP400; USB host/device may be present depending on revision |

| Installation Method | Panel mounting with clips and gasket; front IP65 when correctly installed |

Application Fields

In many cases, the CP435T-ETH ends up on compact machinery and skids where a clean, Ethernet-ready HMI is required:

- Packaging and labeling lines, pick-and-place stations

- Pumps, compressors, and HVAC skids with PLC control

- Water and wastewater compact panels (local operator control)

- Material handling cells and conveyor islands

- Food & beverage auxiliary equipment, mixers, and fillers

One thing I appreciate is how quickly maintenance teams get used to the interface—reducing training time during commissioning. A recent customer on a bottling line mentioned the Ethernet diagnostics helped cut troubleshooting time when a sensor gateway dropped offline.

Advantages & Value

- Reliable and familiar: The CP400 series is known for stable runtime—fewer nuisance reboots in real plant conditions.

- Compatibility: Works smoothly with ABB PLCs (e.g., AC500) and commonly used third-party PLCs via open protocols.

- Cost-conscious choice: For many OEMs, CP400 panels strike a good balance between features and price.

- Lifecycle support: Documentation and firmware are straightforward; spares are easy to manage across multiple machines.

Installation & Maintenance

- Panel & environment: Mount in a sealed cabinet with adequate ventilation. Keep humidity non‑condensing and avoid direct washdown on the rear.

- Power & grounding: 24 VDC supply with proper fusing; tie PE/ground to the cabinet bar to minimize noise. Use ferrules on field terminations.

- Networking & EMC: Use industrial Ethernet cabling (shielded if required). Separate power and signal wiring; follow a clean grounding strategy.

- Routine care: Periodically inspect the front gasket, clean the touchscreen with non‑abrasive wipes, and back up the HMI project. Firmware updates can be applied during scheduled downtime when applicable.

- Safety: De‑energize before servicing; verify absence of voltage. Observe ESD precautions when handling the unit.

Quality & Certifications

- Typically compliant with CE directives for industrial control equipment

- RoHS-conformant materials in most regions

- Manufactured within ISO 9001 quality systems

- Manufacturer’s warranty and conformity documentation available per model revision

Suggested Supporting Components

- ABB AC500 PLC (e.g., PM573-ETH): Seamless Ethernet-based control pairing with the CP435T-ETH.

- ABB S500 I/O modules: Modular I/O for distributed signals, especially useful on skids.

- Industrial 24 VDC PSU (e.g., ABB CP-E 24/2.5): Stable power with overload protection for panel devices.

- Shielded Ethernet patch leads: Helps reduce noise in high-EMI cabinets.

- Panel mounting kit and gasket: Ensures proper compression for front IP65 and clean appearance.

If you’re standardizing HMIs across several machine models, the CP435T-ETH typically offers a clean path to Ethernet diagnostics without pushing the budget. I’m happy to help check protocol and port requirements against your PLC list so there are no surprises during FAT.

Reviews

There are no reviews yet.