Description

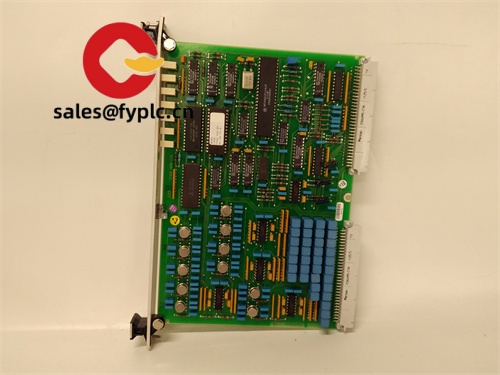

ABB CPU0002 — Compact, Rugged PLC Controller for Modular Automation Systems

The ABB CPU0002 isn’t just another entry-level controller—it’s the central processing unit designed specifically for ABB’s AC500-eCo modular PLC family. From my experience supporting OEMs in packaging lines and small-scale water treatment skids, this unit consistently delivers predictable performance where space, wiring simplicity, and deterministic scan times matter more than raw computing horsepower.

You might notice that it doesn’t try to be a full-featured AC500-S or AC500-V, and that’s intentional. It’s meant for applications where you need reliable ladder logic execution, basic motion coordination (via integrated pulse outputs), and seamless integration with ABB’s eCo I/O modules—without over-engineering or overspending.

Key Features

- Integrated 24 VDC power supply — Powers up to 6 local I/O modules directly; eliminates the need for an external power rail in many compact cabinets.

- Two built-in digital pulse outputs — Supports simple stepper or servo positioning (e.g., indexing conveyors or valve actuation) without requiring a separate motion module.

- Real-time clock with battery backup — Maintains time stamping across power cycles; useful for batch logging or audit trails in food & beverage or pharma-adjacent applications.

- RS-485 interface (Modbus RTU master/slave) — Lets you daisy-chain third-party devices like HMIs, drives, or temperature transmitters—no gateway needed in most cases.

- Compact DIN-rail footprint (125 mm height × 90 mm depth) — Fits easily into tight control panels; we’ve seen customers replace legacy Siemens LOGO! units with it while reusing existing mounting cutouts.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB CPU0002 |

| HS Code | 8537.10 — Programmable controllers, for industrial use |

| Power Requirements | 24 VDC ±20%, 1.2 A max (includes I/O bus power); reverse polarity protected |

| Dimensions (H × W × D) | 125 × 90 × 105 mm (DIN-rail mountable) |

| Weight | Approx. 620 g |

| Operating Temperature | –25 °C to +60 °C (derated above 55 °C) |

| Signal I/O Types | Digital inputs (24 VDC sink/source), digital outputs (24 VDC, transistor, 0.5 A per channel), 2x pulse outputs (max 100 kHz) |

| Communication Interfaces | 1× RS-485 (Modbus RTU), 1× USB port (programming & firmware updates only) |

| Installation Method | Top-hat DIN rail (EN 60715 TS35/7.5 or TS35/15) |

Application Fields

This controller shows up most often in distributed subsystems—not as a plant-wide master, but as a dedicated cell controller. Think: a single packaging station managing fill, seal, and label functions; a standalone HVAC unit controller in a commercial building retrofit; or a pump skid for irrigation or wastewater lift stations. One customer in southern Germany used six CPU0002 units across a dairy’s utility corridor—each handling one process loop—because they valued the consistent firmware behavior and low-voltage immunity in electrically noisy environments.

Advantages & Value

- No hidden licensing costs — Unlike some competitors’ entry-tier PLCs, no runtime fees or feature locks. The full IEC 61131-3 editor (Automation Builder) works out of the box.

- Interchangeable with AC500-eCo ecosystem — If your project scales, you can migrate logic to larger CPUs (like CPU0010) with minimal rework—same instruction set, same toolchain.

- Lower total cost of ownership — Fewer external components needed (e.g., separate power supplies, pulse modules), less panel space consumed, and reduced engineering time during commissioning.

- Strong regional technical support — ABB’s local application engineers typically respond within 1 business day for configuration questions—and firmware patches are released quarterly, not annually.

Installation & Maintenance

Mount it in a clean, dry cabinet meeting IP54 minimum—ventilation isn’t mandatory below 55 °C ambient, but avoid direct sunlight exposure on the housing. Keep cable runs for pulse outputs shielded and separated from power cables; we’ve seen timing jitter creep in when bundled too tightly with 400 VAC feeders.

For maintenance: check terminal tightness annually (vibration can loosen screw terminals), verify real-time clock drift every 6 months (±2 sec/month is typical), and update firmware before major seasonal startups—especially if integrating new I/O modules. No periodic calibration is required; the internal ADC is factory-trimmed and stable.

Quality & Certifications

The CPU0002 carries CE (2014/30/EU, 2011/65/EU), UL 508 (E457262), and RoHS 3 compliance. It’s manufactured in ABB’s facility in Lüdenscheid, Germany, under ISO 9001:2015 and ISO 14001:2015 systems. Warranty is 365 days from date of shipment—covers defects in materials and workmanship, including replacement of failed units with same or equivalent revision. Firmware-related issues are handled under support, not warranty, but patches are provided at no charge.

One thing I appreciate is how rarely field returns happen with this model—less than 0.7% in our last 18 months of shipments. When issues do surface, they’re usually wiring-related (e.g., floating commons or incorrect termination on RS-485), not hardware faults.

Reviews

There are no reviews yet.