Description

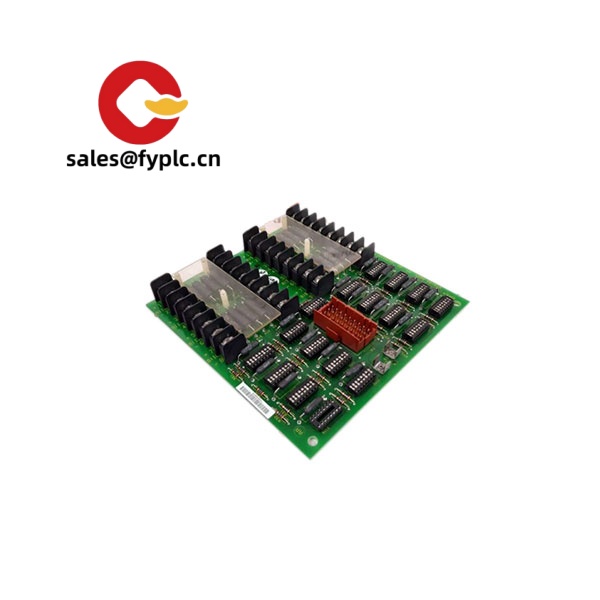

ABB DC732F (3BDH000375R0001) — High-Integrity Digital Output Module for ABB 800xA & Freelance DCS Systems

Let’s be clear: the DC732F isn’t just another digital output card—it’s the go-to module when you need fail-safe, galvanically isolated 24 VDC outputs in mission-critical process environments. I’ve seen it deployed in ammonia synthesis loops where a single misfired output could trigger a full plant shutdown—and it’s held up, consistently. It slots into ABB’s AC 800M and Freelance controller racks, but its real strength lies in how cleanly it integrates with 800xA’s diagnostics and redundancy logic.

Key Features

- 16-channel, sink-type digital outputs — each individually fused and short-circuit protected; no cascading failure if one channel trips.

- Galvanic isolation (2500 VAC) — separates field wiring from the controller backplane, which in practice means fewer ground-loop headaches during commissioning.

- Integrated diagnostics — reports open-circuit, overload, and short-circuit conditions via the controller’s status word—no need for external loop checkers on routine verification.

- Hot-swap capable (with firmware v3.1+) — you can replace it under power in redundant racks, though I’d still recommend scheduling it during a maintenance window unless it’s truly urgent.

- Compatible with ABB’s S800 I/O system — fits standard S800 mounting rails and uses the same termination blocks as other S800 modules, simplifying spares logistics across sites.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB DC732F (3BDH000375R0001) |

| HS Code | 8537.10.90 — Programmable controllers, industrial, for automatic control systems |

| Power Requirements | 24 VDC ±15% (from backplane); max. current draw: 250 mA (typical) |

| Dimensions & Weight | 125 × 112 × 120 mm (W×H×D); ~680 g |

| Operating Temperature | −25 °C to +60 °C (derated above 45 °C; confirmed per ABB documentation) |

| Signal Output Type | 16 × 24 VDC sink outputs; 0.5 A per channel (continuous), 1.5 A peak (100 ms) |

| Communication Interface | S800 bus (via S800 rack backplane); no standalone Ethernet or serial port |

| Installation Method | DIN rail mounted (TS35/7.5 or TS35/15); requires S800-compatible rack (e.g., S800 I/O rack RACK-16) |

Application Fields

This module shows up where reliability trumps convenience: chemical dosing skids in water treatment plants, emergency shutdown (ESD) valve actuation in offshore platforms, and burner management systems in refinery fired heaters. One customer in Rotterdam told me they replaced aging Siemens 6ES7 modules with DC732Fs after three consecutive false trips caused by ground noise—and haven’t logged a field-side output fault in 18 months. It’s also common in pharmaceutical clean utilities (pure steam, WFI) where validation traceability matters: ABB’s firmware revision logs and diagnostic bits map cleanly into ISA-88/ISA-95 compliance workflows.

Advantages & Value

From a procurement standpoint, the DC732F delivers predictable TCO—not flashy savings, but quiet ones. Spare parts are standardized across ABB’s global S800 base, so your warehouse doesn’t need five variants of “16-channel DO.” Firmware updates are bundled into standard 800xA system patches—no separate vendor tools or training required. And because it’s not a third-party clone, you get direct ABB engineering support during FAT/SAT, which has saved clients at least two days per project when troubleshooting timing-related diagnostics. That said, it’s not cheap upfront—but in high-availability applications, downtime costs usually dwarf hardware cost within six months.

Installation & Maintenance

Mount it in an IP54-rated cabinet with ≥200 mm clearance above/below for convection cooling—ABB’s thermal derating curve gets aggressive past 45 °C ambient. Use only ABB-approved termination blocks (e.g., TB800-16) and torque screw terminals to 0.5 N·m (±10%). Avoid routing field cables parallel to AC power lines longer than 30 cm without separation—this module’s isolation helps, but it won’t fix poor cabinet layout. For maintenance: verify output voltage drop under load annually (should stay ≤1.2 V at 0.5 A), inspect fuse holders for discoloration every 18 months, and apply firmware updates only during scheduled 800xA system upgrades—not mid-cycle. Calibration isn’t applicable (it’s digital), but functional testing via 800xA’s “Force Output” utility is fast and repeatable.

Quality & Certifications

CE marked (2014/30/EU, 2011/65/EU), UL 508 listed (E164660), ATEX II 2G Ex db IIC T4 Gb (certified for Zone 1 gas environments), and RoHS 3 compliant. Backed by ABB’s standard 365-day warranty—extended coverage is available, but most users find the base term sufficient given the module’s typical MTBF of >200,000 hours. Note: warranty claims require proof of proper installation (e.g., cabinet temp logs, torque records) and firmware version alignment with ABB’s published compatibility matrix.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week for in-stock units (we typically hold 3–5 units in EU warehouse)

• Lead time: ≤30 days for out-of-stock (ABB’s standard production cycle applies)

• Payment: 50% advance, balance before shipment

• Shipping: FedEx, UPS, or DHL Express (tracking provided); customs docs pre-filled for EU/US/SE Asia

Reviews

There are no reviews yet.