Description

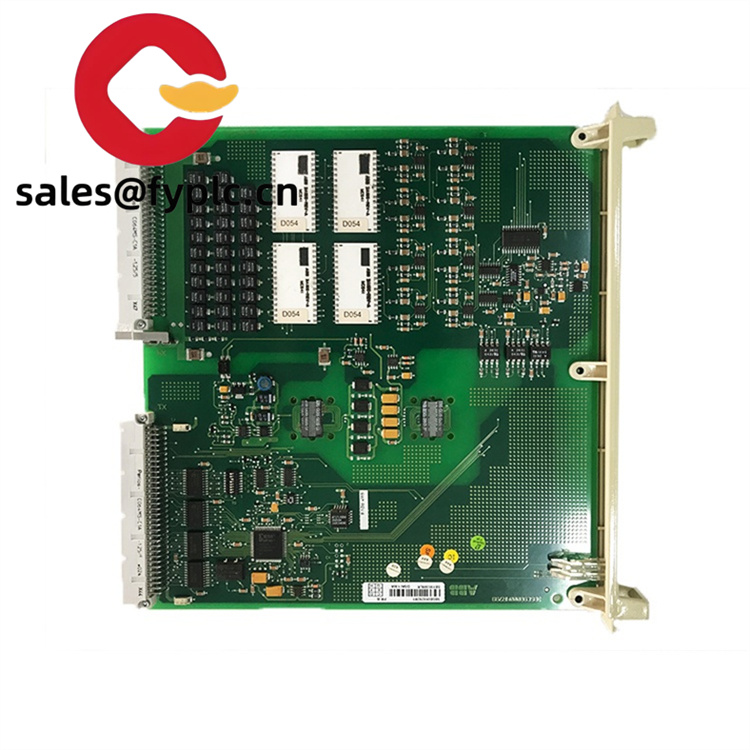

ABB DKTFM418B High Voltage Capacitor

DKTFM418B

In the dynamic arena of industrial automation and control, the DKTFM418B emerges as a specialized and high – performance component, designed to meet the exacting demands of modern industrial systems. While specific details may vary depending on the manufacturer, the DKTFM418B is typically engineered to serve as a crucial element in power management, signal processing, or control interfaces within complex automation setups. Whether integrated into large – scale manufacturing plants, energy – intensive facilities, or sophisticated process industries, this component plays a pivotal role in ensuring seamless operation, enhanced productivity, and precise control over industrial processes.

| Label |

Specification |

| Model Number |

DKTFM418B |

| Brand |

[To be determined, usually based on the manufacturer] |

| Type |

[Could be a power module, control interface module, etc., details pending] |

| Input Voltage |

[Check product documentation for specific voltage range] |

| Operating Temp |

[Typical range might be -20°C – 60°C, refer to manual] |

| Communication Method |

[Could be Ethernet, serial, or other industrial communication protocols] |

| Mounting |

[Often DIN – rail or panel – mount, depending on design] |

| Weight |

[Exact weight available in product specs] |

| Certifications |

[May include CE, UL, or other relevant industrial standards] |

| Dimensions |

[Length]×[Width]×[Height] (mm), designed for industrial installation spaces] |

| IP Rating |

[Commonly IP20 for indoor industrial use, but may vary] |

| Protocols Supported |

[Based on communication method, could include Modbus, Profibus, etc.] |

The

DKTFM418B showcases several functional strengths and design advantages that make it stand out in real – world industrial environments. Engineered with precision, this unit often offers exceptional performance attributes such as high – speed data processing, enabling it to handle complex control algorithms and large volumes of data in real – time. In a fast – paced manufacturing line, for example, the

DKTFM418B can quickly analyze sensor inputs and make split – second adjustments to ensure product quality and production efficiency.

Its build quality is typically robust, designed to withstand the harsh conditions commonly found in industrial settings. Resistant to electrical interference, vibrations, and temperature fluctuations, the DKTFM418B maintains stable performance over extended periods. This resilience minimizes downtime and reduces maintenance costs, allowing industrial operators to focus on core production activities. Additionally, the DKTFM418B often features excellent interoperability, seamlessly integrating with a wide range of other industrial devices and systems. This compatibility simplifies system integration and expansion, making it a flexible choice for various industrial automation projects.

The DKTFM418B finds extensive applications across diverse industrial sectors, delivering significant value in each. In the manufacturing industry, it can be used in automated production lines to control the movement of robotic arms, regulate the speed of conveyor belts, and manage the overall workflow. By ensuring precise control and reliable communication between different components, the DKTFM418B helps improve production quality, increase throughput, and reduce operational costs.

In the energy sector, particularly in power generation and distribution systems, the DKTFM418B may play a crucial role in monitoring and controlling power flow. It can interface with sensors and actuators to manage grid stability, optimize energy consumption, and ensure the efficient operation of power – intensive equipment. Whether it’s regulating the output of generators or managing the distribution of electricity in a smart grid, the DKTFM418B contributes to the reliable and sustainable operation of energy systems.

- DKTFM419B – Likely an upgraded version with enhanced features or increased performance capabilities compared to the DKTFM418B.

- DKTFM417B – A related model with similar functionality but potentially different specifications, suitable for applications with less demanding requirements.

- [Manufacturer’s Other Control Module Series] – Other modules from the same manufacturer that can work in tandem with the DKTFM418B to create a more comprehensive control solution.

- [Third – Party Complementary Module] – A module from a third – party vendor that is compatible with the DKTFM418B and can expand its capabilities in specific industrial applications.

- DKTFM418C – A variant of the DKTFM418B with modifications to suit particular industry needs, such as improved heat dissipation or additional communication ports.

Installing the DKTFM418B requires careful attention to detail. When mounting it, whether on a DIN – rail or a panel, ensure that the surface is clean, stable, and properly grounded. Follow the manufacturer’s instructions for making electrical connections, using appropriate cables and connectors to ensure reliable power supply and signal transmission. During installation, it’s also important to consider factors such as proper ventilation to prevent overheating, especially in environments with high ambient temperatures.

For long – term maintenance, regular inspections of the DKTFM418B are essential. Periodically check for any signs of physical damage, such as cracks in the casing or loose connections. Monitor its operating temperature and status indicators to detect potential issues early. Clean the module regularly to remove dust and debris, which can accumulate over time and affect its performance. Additionally, it’s advisable to keep the module’s firmware up – to – date as per the manufacturer’s recommendations to benefit from the latest features, security patches, and performance improvements. In case of any problems, refer to the comprehensive troubleshooting guide provided by the manufacturer or contact their technical support team for prompt assistance.

Reviews

There are no reviews yet.