Description

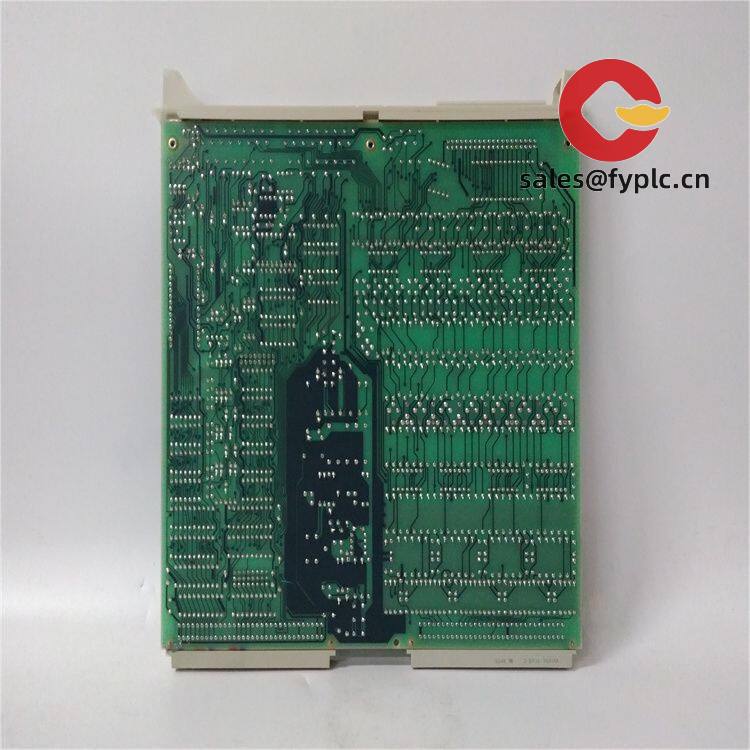

ABB DSAI130 57120001-P5 – Digital I/O Module for Industrial Automation Systems

The ABB DSAI130 is a compact digital signal input module designed for integration into AC 800M control systems, commonly used in process automation environments. From my experience, this module tends to show up most often in retrofit projects or expansions of existing ABB Symphony® or 800xA setups—especially in power plants and water treatment facilities where legacy compatibility matters.

One thing I appreciate is how straightforward it is to deploy—no complex configuration needed beyond standard Control Builder M setup. It handles dry contact inputs reliably, which makes it ideal for monitoring status signals from field devices like pumps, valves, and motor starters.

Key Features

- 16-channel digital input: Accepts 24 VDC dry contacts, typical for interfacing with relay outputs and limit switches.

- High noise immunity: Built-in filtering helps prevent false triggering in electrically noisy environments like substations or motor control centers.

- Modular design: Snap-on mounting compatible with standard DIN rail (EN 60715), integrates seamlessly into existing I/O racks.

- Status indication: Each channel has an LED for real-time feedback—useful during commissioning or troubleshooting.

- Hot-swappable: In most cases, you can replace the module without powering down the entire rack, minimizing downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / DSAI130 (57120001-P5) |

| HS Code | 85371090 |

| Power Requirements | Powered via backplane (typical load: ~120 mA @ 5 VDC) |

| Dimensions & Weight | Approx. 35 mm width, 120 mm height, 118 mm depth / ~280 g |

| Operating Temperature | 0 °C to +60 °C (storage: -40 °C to +85 °C) |

| Signal Input Type | Dry contact (wetted voltage ≤ 24 VDC) |

| Communication Interface | PROFIBUS DP via I/O bus coupling (through CI854/CXxx modules) |

| Installation Method | DIN rail mount (top hat rail, 35 mm) |

Application Fields

This module typically appears in medium-scale industrial applications where discrete monitoring is critical. You might notice it in wastewater lift stations tracking pump run statuses, or in boiler control panels monitoring flame safeguard relays. It’s also found in manufacturing lines using older ABB controllers that haven’t migrated to fully Ethernet-based I/O yet. While newer systems tend to lean toward IP67 fieldbus modules, there’s still strong demand for these rack-mounted units due to their reliability and ease of diagnostics.

Advantages & Value

If you’re managing spare parts inventory for an aging but stable control system, sourcing genuine DSAI130 modules can save significant engineering time compared to redesigning I/O architecture. Compatibility with existing wiring and Control Builder M means minimal revalidation effort. Procurement-wise, it appears that having even a few spares on hand avoids costly production delays when a single channel fails. We’ve seen clients pay more later for emergency swaps—so stocking one or two at strategic intervals seems practical.

Installation & Maintenance

Install only in clean, well-ventilated cabinets meeting IP54 protection standards. Avoid placing near high-power drives unless shielded conduit is used—the input filtering helps, but not infinitely. Wiring should use stranded core with ferrules, especially in vibrating environments. For maintenance, periodic visual inspection of terminal tightness every 12–18 months is advisable. No calibration required, though firmware updates may apply if part of a larger controller upgrade (check ABB Knowledge Store for version history). Hot-swap capability simplifies replacement, but always verify logic interlocks before restoring service.

Quality & Certifications

Complies with CE, UL Listed (File No. E118877), and RoHS directives. Designed and tested per IEC 61131-2 standards for programmable controllers. Original factory-sealed units typically include traceable serial numbers and batch coding. Warranty covers 365 days from date of invoice—covers defects in materials and workmanship under normal operating conditions. Does not cover damage from incorrect wiring, surges, or physical impact.

Delivery: Typically ships within 1 week if in stock; maximum lead time no more than 4 weeks. Payment terms are 50% advance, balance before dispatch. Shipped via FedEx, UPS, or DHL with tracking provided. All units tested prior to shipment.

Reviews

There are no reviews yet.