Description

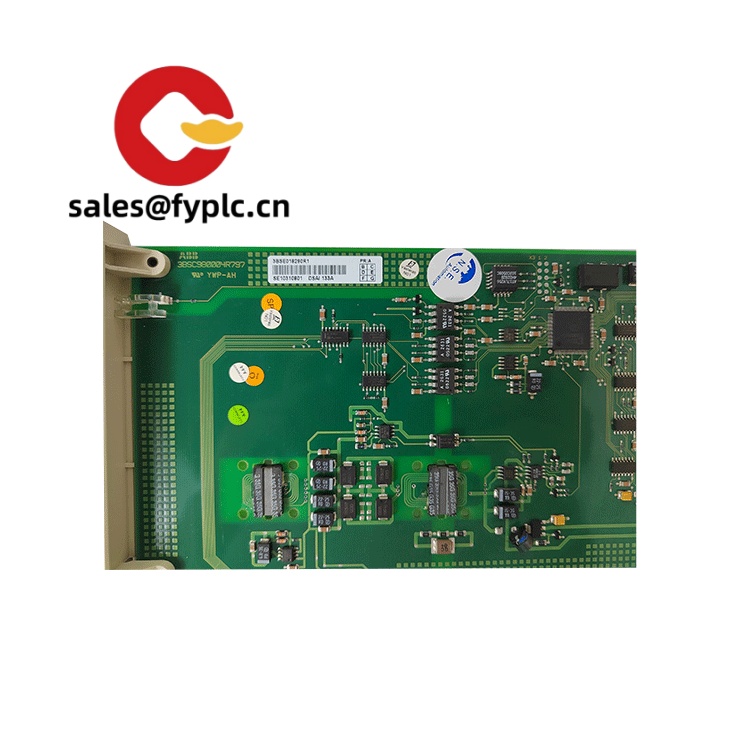

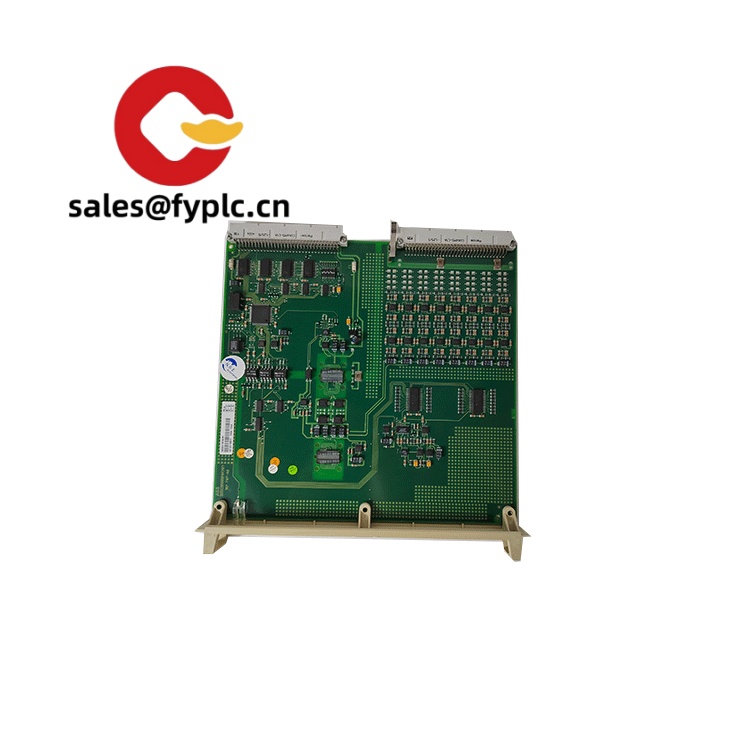

ABB DSAI133A (3BSE018290R1) – Compact Analog Input Module for Stable, Accurate Process Signals

The ABB DSAI133A is a reliable analog input module designed for stable signal acquisition from industrial transmitters and sensors. From my experience, it fits neatly into existing ABB I/O racks and handles typical 4–20 mA and 0–10 V measurements with clean conversion and low drift. You might notice that it’s built for everyday plant realities—fast swap-outs, clear diagnostics, and wiring that doesn’t fight you during commissioning.

Order Placement Process & Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express: FedEx, UPS, DHL (we select the route that typically clears customs fastest for your region)

Key Features

- Multi-channel analog input – Designed for multi-loop acquisition to reduce cabinet footprint and wiring complexity.

- Current and voltage ranges – Supports common industrial signals (4–20 mA and 0–10 V) for transmitters, positioners, and panel instruments.

- Stable, low-noise conversion – Delivers smooth values for PID and advanced control; filtering that, in many cases, cuts nuisance spikes.

- Channel diagnostics – Typical detection for open loop/overrange conditions to speed up troubleshooting.

- Galvanic isolation (field to backplane) – Helps protect the controller side from field disturbances.

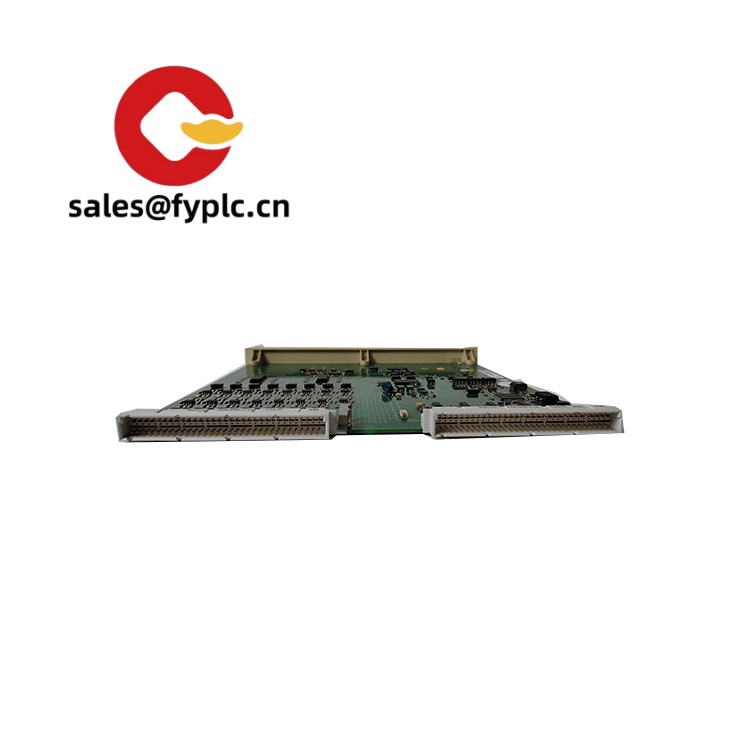

- Hot-swappable form factor – In most cases you can replace the module without rewiring, minimizing downtime.

- DIN-rail MTU/TU installation – Plugs into a terminal unit for quick wiring, tidy shielding, and clean grounding practice.

Technical Specifications

| Brand / Model | ABB DSAI133A – Order code 3BSE018290R1 |

| HS Code | 8538.90 (Parts for switchgear and control panels) |

| Power Requirements | 24 V DC supplied via system backplane/terminal unit; typical consumption around 2–4 W |

| Dimensions & Weight | Approx. 122 × 45 × 102 mm; ~0.2 kg (module only) |

| Operating Temperature | 0 to +55 °C (non-condensing environment is recommended) |

| Signal Input/Output Types | Analog inputs; typical ranges 4–20 mA and 0–10 V; channel-by-channel configuration depending on system engineering |

| Communication Interfaces | Backplane/ModuleBus interface via ABB terminal unit; no external serial/Ethernet port on the module itself |

| Installation Method | Plugs into an ABB MTU/TU on DIN-rail; field wiring lands on the terminal unit; shield/drain grounding supported via TU |

Application Fields

Plants where dependable analog acquisition is the backbone of control: water and wastewater (flow, level, turbidity), oil & gas skids (pressure and temperature loops), power generation balance-of-plant (valves and dampers), chemical dosing, and pulp & paper stock prep. One thing I appreciate is how the module drops into brownfield ABB cabinets with minimal rewiring—handy during phased upgrades.

Advantages & Value

- Reliable drop-in replacement – Typically compatible with existing ABB racks and terminal units, so swaps are fast.

- Lifecycle practicality – Spare stocking is straightforward and field techs already know the wiring pattern.

- Lower downtime risk – Diagnostics and modular design help your team isolate issues in minutes, not hours.

- Cost control – Keeping your ABB backbone while refreshing I/O often costs far less than migrating the whole control layer.

- Technical backing – Documentation is mature and support teams are familiar with the DSAI family’s behaviors.

A maintenance supervisor recently told us a DSAI133A swap restored a noisy level loop without touching the transmitter—seems to be the isolation and input filtering doing the heavy lifting.

Installation & Maintenance

- Cabinet environment – Keep within 0–55 °C, non-condensing; provide ventilation and maintain separation from high-voltage cabling.

- Wiring – Use shielded twisted pair for analog runs; tie shields at the TU end per ABB grounding practice; avoid parallel routes with VFD cables.

- Power – Stable 24 V DC backplane supply; check total I/O load before adding modules.

- Commissioning – Verify channel range configuration (mA vs V) in engineering; validate scaling and alarm limits.

- Routine maintenance – Inspect terminals annually for looseness; clean dust with dry air; review diagnostics; update controller firmware when applicable to maintain I/O compatibility.

- Spares strategy – Keep at least one tested spare; store in anti-static packaging at room temperature.

Quality & Certifications

- CE compliant

- cULus listed (typical for ABB I/O modules in this family)

- RoHS compliant

- Manufactured under ISO 9001 quality systems

- Standard manufacturer’s warranty applies; we back it with a 365-day replacement guarantee

Reviews

There are no reviews yet.