Description

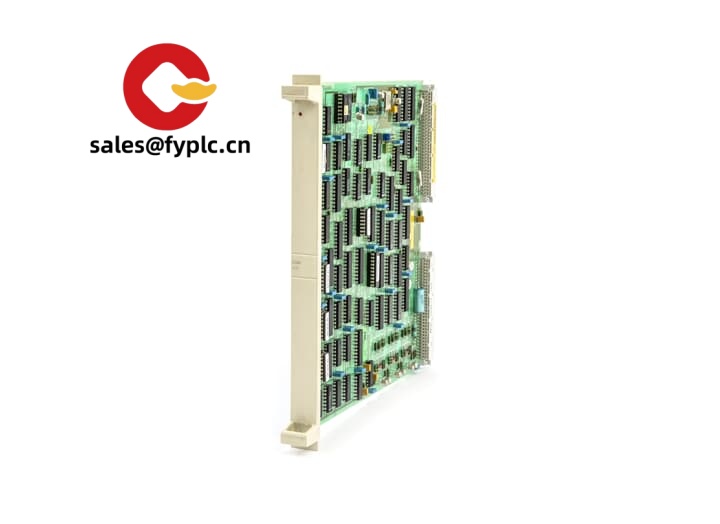

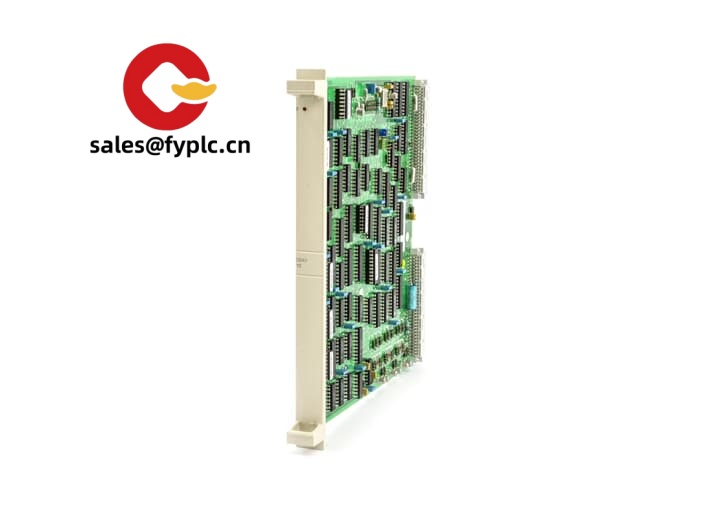

ABB DSAV111 (57350001-CN) – Rack-mounted signal module for legacy Advant/drive systems

The ABB DSAV111, catalog code 57350001-CN, is a plug-in module commonly used in ABB Advant and DC/drive-based control racks for signal handling and system interfacing. From my experience, plants keep this as a direct-replacement spare because it drops into the existing rack, pulls power from the backplane, and restores a failed channel group without re-engineering the cabinet. It’s a practical way to keep mature lines running with minimal disruption.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days coverage

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Backplane-powered: No external PSU needed; the module draws the required voltages directly from the ABB rack.

- Drop-in replacement: Designed to fit the existing subrack footprint for quick swap-outs during maintenance windows.

- Stable, legacy-compatible behavior: Typically used to maintain proven control strategies in running plants without changing I/O maps.

- Robust industrial build: Suited for cabinet environments with continuous operation; ESD-safe handling recommended.

- Traceable part coding: 57350001-CN variant; in many cases the “-CN” denotes regional supply while keeping electrical equivalency with the underlying design.

Technical Specifications

| Brand / Model | ABB DSAV111 (57350001-CN) |

| HS Code | 8538.90 (Parts suitable for apparatus of 8537) |

| Power Requirements | Supplied via system backplane; no separate field power needed for the board itself |

| Dimensions & Weight | Plug-in rack module; compact board-level assembly suitable for standard ABB subracks |

| Operating Temperature | Typically 0 to +55 °C (cabinet environment) |

| Signal I/O Types | Module-level signal handling within ABB control/drive systems; exact channel usage depends on system design |

| Communication Interfaces | Backplane bus interface to the host rack/controller |

| Installation Method | Plug-in card for ABB rack/subrack; field wiring via rack connectors/terminal blocks as per cabinet design |

Application Fields

Plants keep DSAV111 modules on hand where legacy ABB platforms are the backbone of production. Typical scenarios include:

- Metals processing and rolling lines relying on established DC/drive controls

- Pulp & paper machines where Advant-based racks handle critical I/O

- Cement, mining, and bulk material handling with continuous-duty cabinets

- Conventional power and auxiliary systems requiring predictable, stable control

- Marine and test stands that standardize on ABB legacy modules for serviceability

One thing I appreciate is how quickly maintenance teams can swap a failed card and bring a line back up. You might notice that this approach usually avoids requalification work, which is often the hidden cost in modernization projects.

Advantages & Value

- Reliability: Proven field performance; keeps established control loops stable.

- Compatibility: Fits existing ABB racks and backplane—no cabinet redesign.

- Cost control: In many cases, a direct spare is more economical than re-engineering an entire I/O slice.

- Lifecycle support: Ideal for bridging upgrade timelines and reducing production risk.

Installation & Maintenance

- Cabinet environment: Mount in a clean, ventilated enclosure; keep ambient within typical 0–55 °C.

- Rack fitment: Power down the rack unless your site procedures explicitly qualify live insertion for the specific slot. ESD wrist strap is strongly advised.

- Wiring & grounding: Use shielded cables where specified; terminate shields at a single reference point to minimize noise.

- Routine checks: Visual inspection for oxidation, loose connectors, or dust; light cleaning with non-residue electronics cleaner as needed.

- Firmware/parameter notes: If the system architecture stores parameters on the controller, verify configuration after swap. Some sites keep a pre-swap backup to speed validation.

- Spares strategy: Keeping one tested spare per critical rack is, typically, the most economical insurance against downtime.

Quality & Certifications

- Certifications: CE-marked in most cases; UL Recognized status can vary by revision.

- RoHS: Legacy modules may not be RoHS-compliant; many plants accept them in maintenance scenarios.

- Quality system: Manufactured under ABB’s ISO 9001 quality framework.

- Warranty: 365 days repair/replace support as stated above.

Related Supporting Components (commonly paired)

- ABB rack/subrack and backplane assemblies compatible with the DSAV form factor

- Terminal bases or rack connectors used for field wiring breakouts

- Shielded signal cables, grounding kits, and cabinet accessories for EMC performance

Reviews

There are no reviews yet.