Description

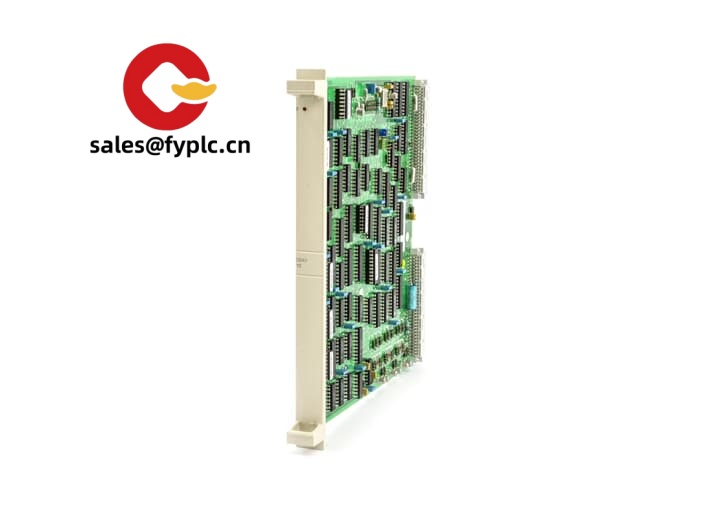

ABB DSAX110A – Special I/O module for Advant S100 installations and long-term plant maintenance

The ABB DSAX110A is part of the Advant (S100) I/O family, designed as a special-purpose module for applications that go beyond standard DI/DO or AI/AO. From my experience, DSAX modules are typically used where fast, event-driven or specialized signal handling is required—think pulse/encoder counting, frequency measurement, or other time-critical signals that standard cards don’t handle elegantly.

If you’re maintaining an installed Advant Master base or bridging legacy I/O to newer controllers, the DSAX110A is often the tidy replacement that keeps downtime low and wiring changes minimal. You might notice that it fits the familiar S100 I/O form factor and works smoothly with common Advant racks; in many cases it also integrates into AC 800M systems via the S100 I/O interface.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Special I/O for time‑critical signals – Typically used for counters, pulse/encoder inputs, or frequency capture where deterministic performance is needed.

- Advant S100 rack compatibility – Fits the established S100 I/O ecosystem, making retrofit and like‑for‑like replacements straightforward.

- Stable plant lifecycle support – Keeps legacy lines running with minimal re-engineering; parts, wiring style, and diagnostics feel familiar to maintenance teams.

- Backplane powered – Power typically supplied from the S100 backplane; field side uses standard 24 VDC conventions when applicable.

- Service-friendly terminals – Front access terminals reduce panel work and speed up turnaround during planned outages.

- Controller compatibility – Commonly used with Advant Master controllers; in many cases can be integrated with AC 800M via the S100 interface module.

Technical Specifications

| Brand / Model | ABB DSAX110A (Advant S100 I/O family) |

| HS Code | 8538.90.0000 (Parts suitable for switchgear/PLC assemblies) |

| Power Requirements | From S100 backplane (typical); field supply 24 VDC where applicable |

| Dimensions & Weight | S100 I/O module form factor; approx. 170–190 mm (H) × 80 mm (W) × 115 mm (D), ~0.3–0.5 kg |

| Operating Temperature | 0 to +55 °C (typical for ABB I/O in control cabinets) |

| Signal Input/Output Types | Special I/O; typically used for high‑speed counting, pulse or encoder signals, and similar time‑based measurements |

| Communication Interfaces | S100 I/O backplane; front terminal connections for field signals |

| Installation Method | Mounts on Advant S100 I/O rack/base; cabinet installation per IEC/UL practices |

Note: The DSAX series is a special-function family; exact channel counts and signal styles can vary by revision. If you share your existing rack layout or controller type, we’ll match firmware and hardware revisions before shipping.

Application Fields

- Steel and metals: line speed monitoring, encoder feedback on payoffs and recoilers

- Pulp & paper: web break detection, roll diameter calculation via pulse counting

- Chemicals & refining: turbine flowmeter pulse inputs, fast batch event timing

- Utilities: generator or turbine shaft speed pulses, overspeed trip channeling

- General machinery: position/length measurement with incremental encoders

Advantages & Value

- Low risk swap‑in – Like‑for‑like module keeps wiring, cabinet layout, and logic changes minimal.

- Compatibility – Works within Advant S100 I/O racks; in many cases it’s also supported from AC 800M via an S100 interface module.

- Cost control – Extends the lifecycle of existing assets; avoids rushed platform migrations.

- Pre‑shipment testing – We can power-on test and provide photos of diagnostics screens on request.

A maintenance lead from a metals plant told us, “Swapping the DSAX110A kept our encoder logic untouched—we were back up during the same shift.” That seems to be the core value here: minimal disruption.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated control cabinet. Keep ambient 0…+55 °C and humidity non‑condensing.

- Wiring – Use shielded cabling for pulse/encoder lines; ground shields at one end to reduce noise. Separate low‑level signals from power lines.

- Backplane & seating – Ensure the S100 module is fully seated on the base and locking tabs engaged before energizing.

- Safety – De-energize field circuits before removal. Verify proper earthing of the cabinet and I/O base.

- Routine checks – Periodically inspect terminal tightness, clean dust with dry air, and verify counter/encoder scaling in the controller after any mechanical service.

- Firmware/config – Where applicable, align module firmware and application configuration with your controller revision; keep a backup of the I/O mapping.

Quality & Certifications

- Manufacturer quality system: ISO 9001 (ABB)

- Conformity: CE marking (EMC/Low Voltage) and RoHS (typical for ABB I/O)

- Safety listings: UL/CSA where applicable to the I/O family

- Warranty: 365 days hardware warranty through us

Supporting Components (for planning)

- Advant S100 I/O racks/bases and terminal blocks (existing installed base typically reused)

- Advant Master controllers (e.g., AC 410/AC 450) in legacy systems

- AC 800M with S100 I/O interface (commonly CI855) for mixed or migration setups

If you can share your rack type, controller model, and the exact signals you plan to land on the DSAX110A, I’ll double‑check compatibility and reserve the right revision so it drops in smoothly.

Reviews

There are no reviews yet.