Description

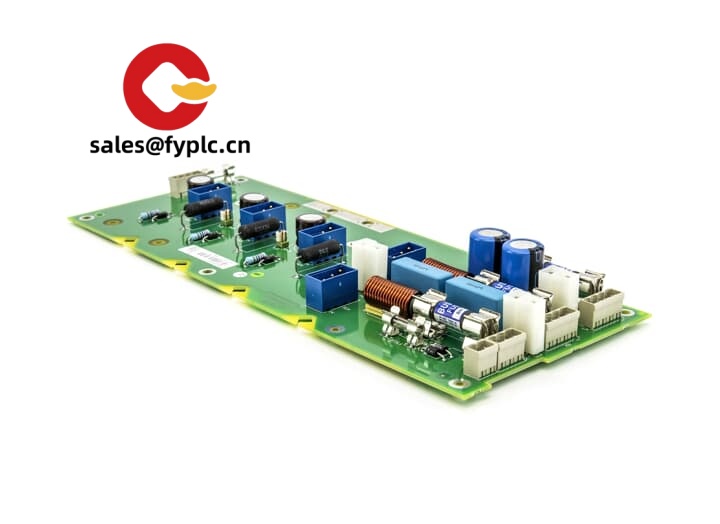

ABB DSAX452 – Communication Interface Module for Advant AC 400/800xA Systems

The ABB DSAX452 is a communication interface module commonly used in Advant Controller AC 400 installations (and in many cases supervised by 800xA). From my experience, it’s chosen when you need a reliable way to link legacy or third‑party serial/field devices—like drives, analyzers, panel instruments, or package PLCs—into an Advant control environment without redesigning the whole architecture. You might notice that the strength of the DSAX452 isn’t flashy specs; it’s stable comms, straightforward diagnostics, and long-term support for installed-base plants.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Advant backplane integration – Fits into the AC 400 ecosystem, so engineering and diagnostics typically remain familiar to plant teams.

- Stable serial/field connectivity – Designed to interface with external devices where deterministic, low‑overhead links are preferred.

- Front‑panel indicators – LEDs make it easy to check communication status and basic health at a glance.

- Industrial temperature rating – Built for control cabinets in process plants; performs reliably in typical 0–55°C environments.

- No external power supply – Powered via the controller backplane, which keeps wiring and maintenance simple.

- Lifecycle-friendly – A practical path to keep legacy serial instruments and drives talking to modern operator systems on 800xA.

Technical Specifications

| Brand / Model | ABB DSAX452 |

| HS Code | 8538.90 (Parts for switching/protection/control apparatus) |

| Power Requirements | Backplane powered (Advant rack); no separate external supply typically required |

| Dimensions & Weight | Advant rack module, 1‑slot width; approx. 0.4–0.6 kg (typical module format) |

| Operating Temperature | 0 to +55 °C (typical control cabinet conditions) |

| Signal I/O Types | Serial/field communication channels for external devices (protocol and wiring depend on configuration/firmware) |

| Communication Interfaces | Advant system backplane; front connectors for field/serial lines (model‑specific) |

| Installation Method | Installs in AC 400 series controller rack; field wiring via front connector/terminal as per ABB documentation |

Application Fields

Plants that keep a solid Advant installed base typically use the DSAX452 to pull in serial or device‑level data where Ethernet wasn’t originally available. Common cases include:

- Process industries (chemicals, oil & gas, power, pulp & paper) — linking analyzers, metering skids, or packaged units into AC 400.

- Metals, mining, and cement — integrating legacy drives and weighers that communicate over simple serial protocols.

- Utilities and water — connecting RTUs, panels, or OEM controllers to central logic without full system retrofits.

One thing I appreciate is how it lets you bridge older devices into 800xA operator workplaces with minimal disruption. A maintenance lead told us they swapped a failed interface card and were trending data again in under an hour because the wiring stayed identical.

Advantages & Value

- Reliability for installed base – In many cases, it’s a straightforward one‑for‑one replacement that minimizes downtime.

- Engineering continuity – Keeps existing control strategies and faceplates; less revalidation and no risky rewiring.

- Cost control – Extends asset life of legacy serial devices instead of forcing a premature network migration.

- Compatibility – Designed for the Advant/AC 400 ecosystem and typically plays well with 800xA supervision.

- Supported by spares strategy – Easier to stock and swap during planned outages, especially in multi‑unit plants.

Installation & Maintenance

- Cabinet & environment – Mount in a clean, dry control cabinet; follow ABB rack guidelines. Provide ventilation to keep internal temps in the typical 0–55°C range.

- Wiring – Use shielded twisted pairs for serial lines; terminate and ground shields at one end to avoid loops. Keep power and signal separate to minimize noise.

- Commissioning – Configure communication parameters (baud, parity, addressing) in the engineering tool; verify with front LEDs and loopback/device tests.

- Safety – De‑energize the rack slot before insertion/removal unless ABB documentation explicitly permits otherwise. Observe ESD protection.

- Routine upkeep – Periodically inspect connectors, clean dust with dry air, review diagnostics for error counters, and apply firmware/definition updates when released by ABB.

Quality & Certifications

- CE compliant; RoHS alignment typically observed for spare modules in current circulation.

- Manufacturing and quality under ABB’s established procedures; many site approvals include ISO‑based QMS.

- Manufacturer’s warranty support; our supply includes a 365‑day warranty as stated above.

Related Components (for planning)

Plants typically keep companion spares such as DSDI/DSDO (digital I/O), DSAI/DSAO (analog I/O) modules, and relevant front connectors/terminal kits. If you’re refreshing an AC 400 rack, it often makes sense to review DSAX variants alongside CPU and power supply modules to balance lifecycle risk.

Reviews

There are no reviews yet.