Description

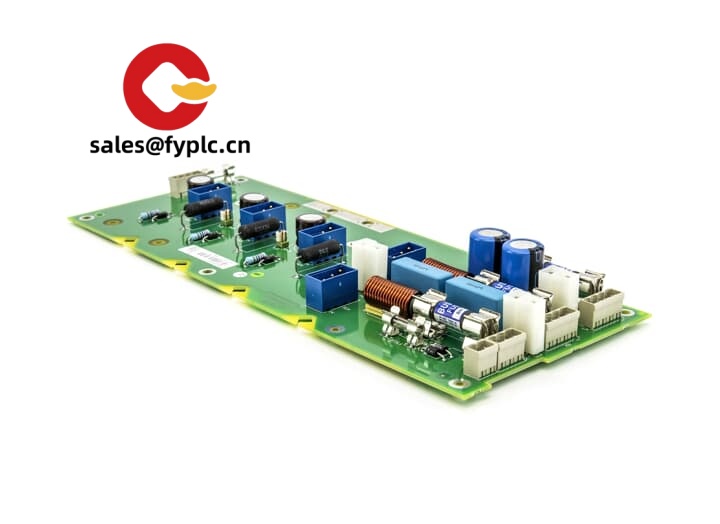

ABB DSBB188 (3BSE005004R1) – Advant Master S100 I/O Bus Interface/Buffer Module for Legacy and 800xA Systems

The ABB DSBB188, part number 3BSE005004R1, belongs to the Advant Master S100 I/O family and is typically used as a bus interface/buffer element within S100 racks. From my experience, plants use it to maintain stable I/O bus communication across installed DSAI/DSAO/DSDI/DSDO cards and to support staged migrations to AC 800M/800xA without tearing out proven cabinets. You might notice that it’s often specified when an S100 I/O segment needs higher reliability or a like-for-like replacement to minimize downtime.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment terms: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Advant S100 bus interface/buffer – Designed to work within S100 I/O racks, stabilizing the I/O backplane bus in typical process cabinets.

- Migration-friendly – Commonly used in brownfield upgrades to AC 800M/800xA, helping keep existing wiring and terminations intact.

- Backplane powered – Draws power from the S100 rack; no separate field supply typically required, which simplifies wiring.

- Ruggedized for industry – Built for continuous operation in control rooms or MCC environments found in power, oil & gas, and pulp & paper.

- Status indication – Front-panel LEDs (on most builds) give quick visual diagnostics for maintenance crews.

- Compatibility with S100 I/O – Works alongside DSAI/DSAO/DSDI/DSDO families and DSBC bus controllers found in many Advant Master systems.

Technical Specifications

| Brand / Model | ABB DSBB188 (3BSE005004R1) |

| HS Code | 8537.10 (Programmable control equipment and related modules) |

| Power Requirements | Via S100 backplane (5 VDC typical, low-watt consumption) |

| Dimensions & Weight | S100-format plug-in module; Eurocard-style depth (approx. 100 × 160 mm), ~0.3–0.5 kg typical |

| Operating Temperature | 0…55 °C typical control-room conditions (non-condensing) |

| Signal Input/Output Types | Not a field I/O module; functions as a bus/interface element for the S100 I/O backplane |

| Communication Interfaces | S100 I/O backplane bus (rack-internal) |

| Installation Method | Plug-in card for S100 I/O rack; front service access with ESD-safe handling |

Note: Values above reflect typical characteristics for S100 bus/interface modules in this family. For site acceptance or regulated environments, it’s best to verify against your exact cabinet build and ABB documentation revision.

Application Fields

Plants running Advant Master or 800xA with S100 I/O racks will typically deploy DSBB188 in:

- Power generation and district heating – supporting turbine balance-of-plant I/O bus segments.

- Oil & gas and petrochemicals – maintaining reliable I/O communication in ESD/PCS cabinets.

- Pulp & paper – stabilizing long-running S100 racks in wet, high-vibration areas (inside conditioned cabinets).

- Metals and mining – extending service life of existing I/O with minimal re-wiring during upgrades.

- Water & wastewater – cost-effective replacement for aging bus cards in control rooms.

One thing I appreciate is how it helps teams avoid rushed, full-cabinet replacements. A maintenance lead at a combined-cycle site told me they swapped a failed DSBB188 during a short outage and brought the entire S100 segment back without re-terminating a single field cable.

Advantages & Value

- Drop-in compatibility – Keeps the existing S100 rack, wiring, and documentation intact.

- Reduced downtime – Fast swap-out in most cabinets; common spares strategy across units.

- Lifecycle extension – Helps defer capital-intensive rewiring when migrating to AC 800M/800xA.

- Proven reliability – Stable performance in continuous-process environments.

- Technical support – Guidance on rack slotting, bus integrity checks, and migration planning.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated S100 cabinet; maintain ambient 0…55 °C and non-condensing humidity.

- Wiring and grounding – Verify rack grounding and shielding continuity; inspect bus terminations and connectors during installation.

- ESD safety – Use ESD straps and antistatic packaging; avoid touching connector pins.

- Insertion/removal – De-energize the rack unless your site procedure specifies otherwise; check seating and locking levers.

- Routine care – Annual dust cleaning with dry air, connector inspection, and visual check of any status LEDs.

- Firmware/config – As a bus/interface element, it usually requires no field firmware handling; controller configuration should be reviewed after hardware changes.

Quality & Certifications

- Manufacturer compliance: CE-marked on most production runs; UL recognition appears on many S100 assemblies.

- RoHS: Varies by manufacturing vintage; many installed-base spares pre-date current RoHS directives.

- Warranty: 365 days (repair/replace as applicable under normal use).

Commonly Paired Components

- DSAI / DSDI / DSAO / DSDO series – Analog and digital I/O cards in the S100 family.

- DSBC bus controller modules – For S100 I/O bus supervision and communication.

- Advant Master controllers or AC 800M (800xA) – In mixed or migrated architectures.

If you want, share your rack type and slot plan, and I’ll sanity-check compatibility and the spares list. In many cases, a quick look at the cabinet photo is enough to confirm the DSBB188 position and any bus terminator requirements.

Reviews

There are no reviews yet.