Description

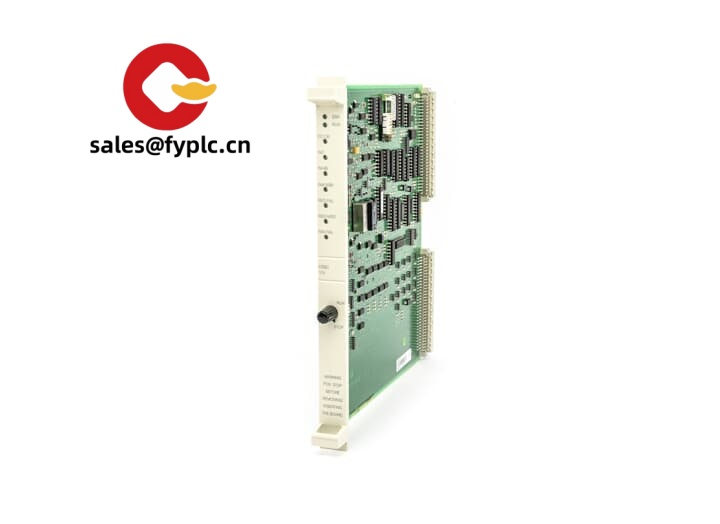

ABB DSBC176K01 (3BSE019956R1) – Communication Board for Advant/800xA Legacy Networks

The ABB DSBC176K01, part no. 3BSE019956R1, is a communication board used in many Advant and 800xA life‑cycle systems to maintain stable, redundant plant networking. From my experience, engineers typically fit this board where MasterBus 300–based segments are still in service and uptime matters more than a full platform migration. It’s a practical, field‑proven spare when you need to keep existing cabinets running reliably, avoid unplanned downtime, and buy time for phased upgrades.

Our Order Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Packing & ESD handling: anti-static packaging, foam protection, and device labeling for traceability

Key Features

- Designed for legacy continuity: Suited for Advant/800xA environments where MasterBus 300 networks remain part of the control backbone.

- Redundancy-friendly layout: Typically supports redundant bus architecture, which helps reduce single-point failures in critical loops.

- K01 hardware variant: The K01 revision is commonly selected for drop‑in replacement compatibility across installed bases.

- Diagnostics at a glance: Clear front indicators make it easier to spot bus status and perform quick health checks during shifts.

- Stable in harsh panels: Industrial‑grade design for 24 VDC control power and cabinet environments found in process plants.

- Lifecycle spare strategy: Helps extend service life of running units without immediate software or cabinet redesign.

Technical Specifications

| Brand / Model | ABB DSBC176K01 (3BSE019956R1) |

| HS Code | 8537.10 – Programmable controllers (for voltage ≤ 1000 V) |

| Power Requirements | 24 VDC nominal (typical control cabinet supply) |

| Operating Temperature | 0 to +55 °C (typical control cabinet conditions) |

| Signal Input/Output Types | Industrial fieldbus communication for legacy plant networks (MasterBus 300–class) |

| Communication Interfaces | Redundant bus ports for plant network connectivity; front status LEDs for diagnostics |

| Installation Method | Plug‑in module for ABB control racks/subracks; observe ESD precautions and slotting rules per ABB manual |

| Dimensions & Weight | Compact plug‑in board (1-slot form factor), typically under 0.5 kg |

Application Fields

Plants still running Advant or mixed 800xA/Advant architectures typically keep DSBC176K01 in stock for network resilience. You might notice it most in:

- Power generation (base‑load units, balance‑of‑plant controls)

- Oil & gas (gathering, refining, utilities)

- Pulp & paper (continuous process lines, recovery boilers)

- Chemicals & petrochem (utilities, interlocks, ESD layers that interface with legacy bus)

- Metals & mining (rolling, material handling, local MCC integrations)

A maintenance lead in a paper mill told us they swapped in DSBC176K01 during a Saturday window and were back on spec in under an hour—no rework of cabinets, just a clean replacement and bus check.

Advantages & Value for Procurement

- Reliability under legacy constraints: Keeps proven field networks running with predictable behavior.

- Compatibility: K01 variant aligns with widely installed system revisions, easing spare pooling.

- Cost containment: In many cases, a board replacement is more economical than fast‑tracking a system migration.

- Short downtime: Straightforward swap reduces startup delays and engineering hours.

- Supportable lifecycle: Fits a staged modernization plan—replace today, migrate on your timeline.

Installation & Maintenance

- Cabinet environment: Clean, ventilated control cabinet; avoid high vibration and corrosive atmospheres. Keep ambient 0–55 °C where possible.

- Power & grounding: 24 VDC control power with stable grounding; route shields to a single point to minimize noise.

- Network cabling: Use plant‑standard cabling for the bus (as specified for your MasterBus 300 installation). Maintain proper termination and redundancy layout.

- Handling: ESD protection and power‑down before insertion/removal unless your procedure explicitly allows hot‑work for this slot.

- Routine checks: Inspect connectors and LED status during rounds; verify node addressing and bus health after maintenance.

- Documentation: Keep firmware/hardware revision notes in the cabinet log; it seems to be the quickest way to correlate spares across units.

Compatible & Supporting Components (examples)

- Advant Controllers (e.g., AC 450 family): Typical host environments where DSBC‑series communication boards are deployed.

- Legacy I/O modules (e.g., DSAI/DSDI series): Analog and digital I/O families frequently tied to MasterBus 300 networks.

- Network accessories: Approved bus cables, terminators, and repeaters to sustain redundancy and segment lengths.

- Power conditioning: 24 VDC supplies with surge protection for stable board operation.

Quality & Certifications

- Certifications: CE compliant; RoHS alignment typical for modern supply. Many installations also adhere to ISO 9001 quality frameworks at the plant level.

- Manufacturer policy: ABB publishes product‑specific conformity and lifecycle notes; please align with your site’s validated revision list.

- Our warranty: 365 days from delivery. Units are tested before dispatch and packed for ESD safety.

If you’re standardizing spares across multiple sites, share the exact board revision on your running units. Matching the K01 hardware and the 3BSE019956R1 part number typically shortens FAT/SAT checks and avoids unnecessary bus reconfiguration.

Reviews

There are no reviews yet.