|

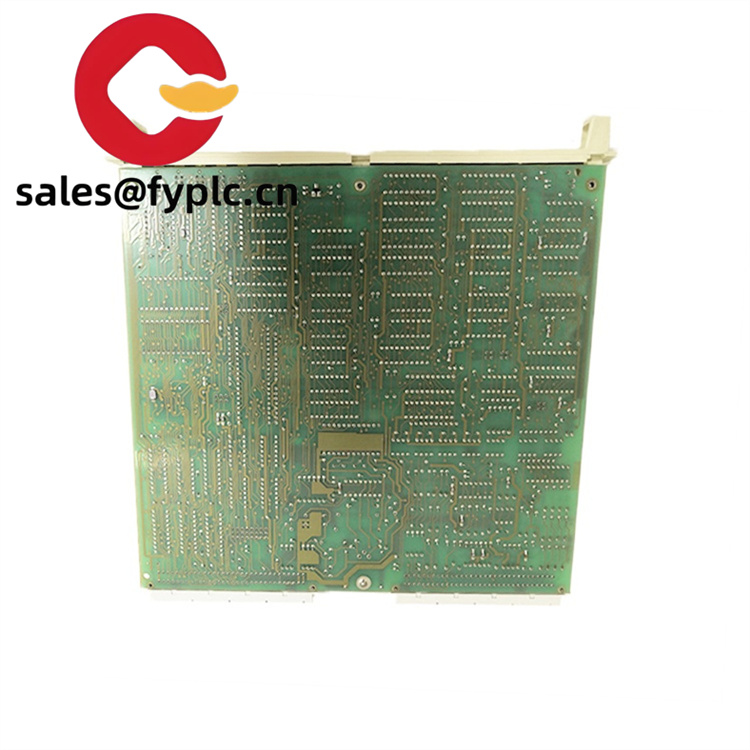

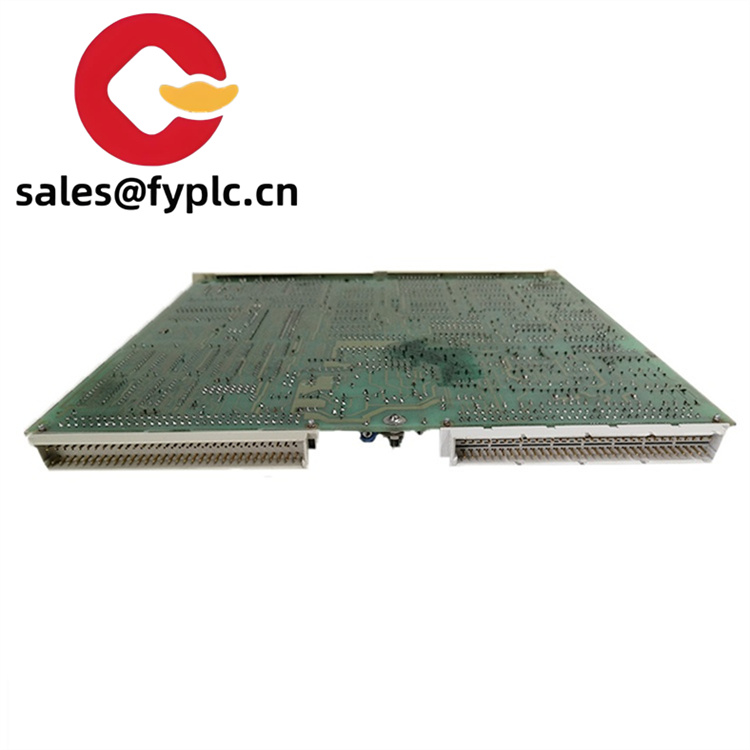

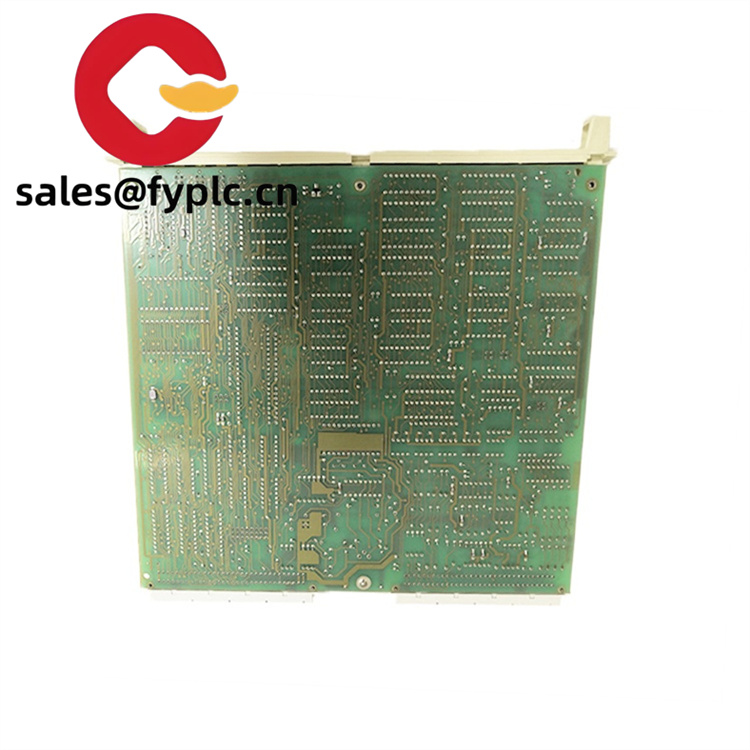

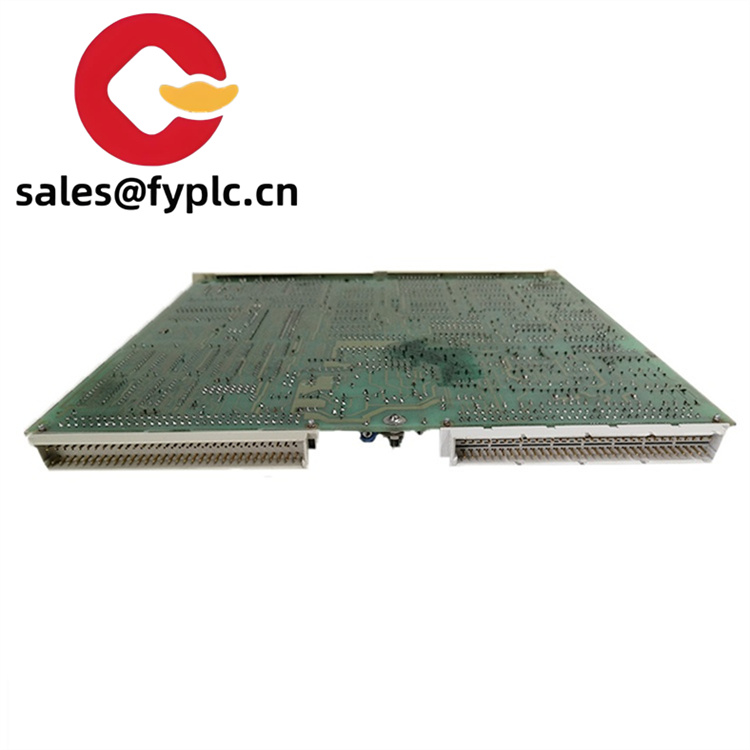

Label

|

Specification

|

|

Model Number

|

DSDP140B

|

|

Brand

|

ABB

|

|

Type

|

Position Control and Communication Module

|

|

Input Signals

|

Compatible with various encoder signals for position feedback

|

|

Output Signals

|

Precise control signals for actuators and motors

|

|

Communication Protocols

|

Supports industry – standard protocols like Profibus DP for seamless integration

|

|

Operating Temperature

|

Designed to function optimally within a wide temperature range, typically – 40°C to + 70°C

|

|

Mounting Method

|

Easy – to – install rack – mountable design for convenient integration into existing setups

|

|

Weight

|

[Insert specific weight value here]

|

|

Certifications

|

Complies with relevant international certifications, ensuring high – quality and safe operation

|

|

Dimensions

|

[Specify length, width, and height dimensions]

|

|

IP Rating

|

[Mention the appropriate IP rating if applicable]

|

One of the remarkable functional strengths of the ABB DSDP140B lies in its high – precision position control capabilities. Engineered with advanced algorithms and signal processing techniques, this module can accurately detect the position of motors or other moving components based on encoder feedback. This precision is vital in applications such as high – speed manufacturing lines, where even the slightest deviation in position can lead to product defects or production inefficiencies. Operators benefit from the module’s ability to provide real – time and accurate position data, allowing for prompt adjustments and optimal control.

In terms of design advantages, the DSDP140B is built to be highly resilient and reliable. Its robust construction enables it to withstand the harsh environmental conditions often encountered in industrial settings, including electrical noise, vibrations, and temperature fluctuations. Additionally, its compatibility with a wide range of industrial communication protocols makes it incredibly versatile. It can easily interface with other components in the automation system, whether they are from ABB or other leading manufacturers, promoting seamless interoperability and system integration.

DSCS131B

The ABB DSDP140B finds extensive use in a variety of industrial scenarios. In the metals and mining industry, for example, it can be deployed in conveyor systems to precisely control the movement of materials. By accurately positioning the conveyor belts and associated machinery, it helps prevent material spillage and ensures efficient transportation of ores and other minerals. In the food and beverage manufacturing sector, the DSDP140B is invaluable for controlling the movement of packaging machinery. It ensures that products are accurately filled, sealed, and labeled, maintaining high – quality standards and reducing waste.

In a DCS environment, the DSDP140B works in harmony with other control modules to provide comprehensive process control. It can receive signals from various sensors and transmit control commands to actuators, ensuring that the entire production process runs smoothly. In a SCADA system, it plays a crucial role in monitoring and controlling remote equipment, enabling operators to have real – time visibility and control over industrial processes from a central location.

DSCS131B

Several models are closely related to the ABB DSDP140B. The DSDP150 is often paired with the DSDP140B in applications where additional counting functions are required. It can work in tandem to enhance the overall control capabilities, such as in high – speed counting applications for accurate product counting on a production line. The DSAI130D is another related module that, while having different primary functions (focusing more on analog input), can be integrated with the DSDP140B in complex industrial control systems to handle both analog and position – related data. The 5SHX0660F0002 is a component that may interact with the DSDP140B in power – related applications within an industrial setup, ensuring stable power supply for the module and associated equipment. The DSCS131B is a communication – focused module that can collaborate with the DSDP140B to enhance data transfer and communication within the automation system. The DCV700 system is often used in conjunction with the DSDP140B to control motors, with the module providing the necessary position – related data for precise motor control.

Installing the ABB DSDP140B requires careful attention to detail. When mounting the module, it should be securely fixed in the designated rack, ensuring proper alignment to prevent any physical damage during operation. Wiring connections must be made precisely, following the provided wiring diagrams to avoid signal interference and ensure accurate data transfer. Grounding the module correctly is of utmost importance, as it helps protect against electrical surges and noise, which could otherwise affect the module’s performance.

For long – term maintenance, regular inspections are essential. Operators should periodically check for any signs of loose connections, physical wear and tear, or abnormal heat generation. Monitoring the module’s performance metrics, such as position accuracy and communication latency, can help detect potential issues early on. Additionally, keeping the module’s software and firmware up – to – date is crucial, as it often includes performance enhancements and bug fixes that can improve the module’s reliability and functionality.

DSCS131B

Reviews

There are no reviews yet.