Description

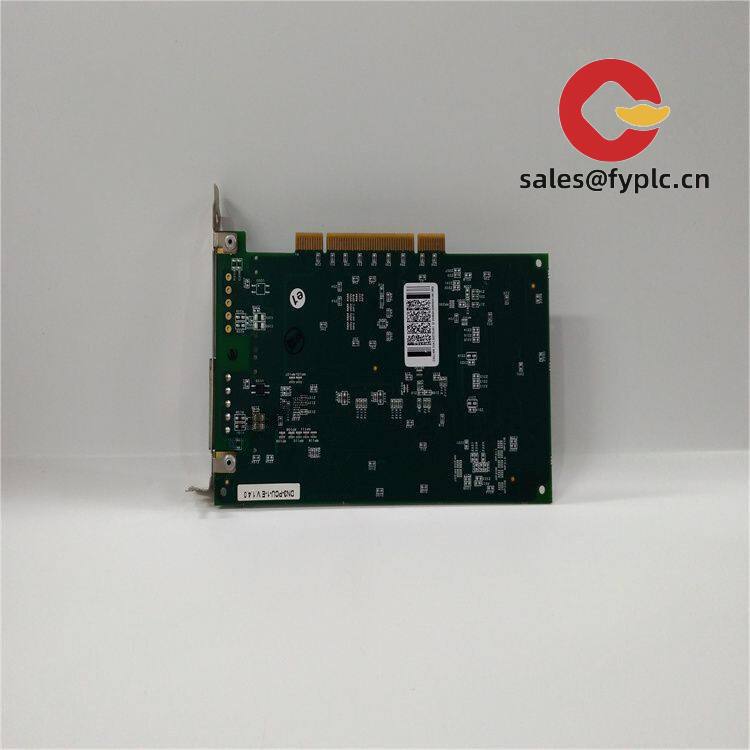

ABB DSQC658 (3HAC025779-001) Bus Module – Reliable fieldbus coupling for ABB robot I/O integration

The DSQC658 3HAC025779-001 is a bus module used in ABB robot controller systems to bridge the controller’s backplane with a plant-level I/O network. From my experience, it’s the piece that quietly keeps the robot talking to your sensors, valves, safety relays, and PLCs—day in, day out. One thing I appreciate is how predictable it feels in production: when the controller boots, I/O comes up quickly and stays stable, which is exactly what you want on a welding line or a high-speed packaging cell.

Typical scenarios include expanding digital/analog I/O on an IRC5-based cell, tying robots into existing fieldbus segments, or restoring communication after a failed bus coupler. You might notice that sites standardize on this module because it’s straightforward to replace and doesn’t force changes to upstream PLC logic.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Shipping: FedEx, UPS, DHL (express)

- Condition & testing: Each unit is visually inspected and function-tested prior to dispatch, with traceable records kept on file

Key Features

- Purpose-built bus coupler: Interfaces the ABB controller’s backplane to a field I/O network so the robot can exchange process data reliably.

- Stable cabinet-grade design: Engineered for continuous operation in enclosed control cabinets; typically handles normal plant temperatures without fuss.

- Predictable startup behavior: Fast I/O discovery and mapping after power cycles, which helps minimize downtime during shift changes and maintenance windows.

- Service-friendly replacement: Module swap and re-seating is typically quick, reducing MTTR in most cases.

- Compatible with ABB robot controllers: Used in ABB robotic cells where backplane-to-fieldbus communication is required (verify against your controller option list).

- Diagnostic indicators: Status LEDs for power and bus state make first-line troubleshooting straightforward on the cabinet door.

Technical Specifications

| Brand / Model | ABB DSQC658, Part No. 3HAC025779-001 |

| HS Code | 8538.90 (Parts suitable for apparatus of 8536/8537) |

| Power Requirements | 24 VDC supply from controller (cabinet internal), typical |

| Dimensions & Weight | Compact controller-module format; typically < 0.6 kg; cabinet-mounted footprint |

| Operating Temperature | 0 to +45 °C inside a ventilated control cabinet (typical) |

| Signal I/O Types | Process data over fieldbus (no direct discrete terminals on the module) |

| Communication Interfaces | Controller backplane interface; external fieldbus port as configured by the system option (verify protocol on your installed unit) |

| Installation Method | Mounted inside ABB robot controller cabinet; secured to the designated location/rail with backplane connection |

Application Fields

This module is commonly deployed in robotic cells where the controller must communicate with distributed I/O or a plant PLC network. Typical uses include:

- Automotive welding lines—coordinating gun actuators, fixture clamps, and interlocks

- Material handling and palletizing—reading photoeyes and driving diverters on conveyors

- Machine tending—exchanging signals with CNCs, part presence sensors, and safety gates

- General assembly—scalable I/O for screwdriving, pressing, and inspection stations

Field feedback from a Tier-1 integrator: “Swapped in a DSQC658 during a night shift and the I/O scan was back in under 10 minutes. No PLC changes needed.” That’s fairly typical when the module is correctly mapped and the cabinet is in good condition.

Advantages & Value

- Reliability: Designed for continuous operation; fewer nuisance trips and recoveries compared with improvised gateways.

- Compatibility: Works within ABB robot controller architecture, preserving your existing signal map in most cases.

- Lower lifecycle cost: Quick swap capability and clear diagnostics shorten downtime and reduce maintenance hours.

- Support & documentation: Well-documented in ABB service manuals, which makes commissioning and troubleshooting more predictable.

Installation & Maintenance

- Cabinet environment: Install in a clean, dry control cabinet meeting IP-rated standards; allow adequate ventilation around modules.

- Power & grounding: Use the controller’s 24 VDC supply; maintain solid protective earth and shield grounding to limit EMI.

- Wiring practices: Route fieldbus cabling separately from high-voltage motor leads; maintain correct bus termination and segment length per the protocol used.

- Commissioning: After installation, verify node addresses, I/O mapping, and LED status; perform a cold start and confirm stable bus state.

- Routine checks: Inspect connectors quarterly; clean dust with dry air; confirm firmware/option set aligns with the controller backup.

- Spare strategy: Keeping one tested spare on site typically pays for itself after a single avoided production stop.

Quality & Certifications

- Manufacturer compliance: CE marking; RoHS compliance is typical for modern ABB control modules

- UL/CSA: Often recognized/listed when installed in compliant control cabinets (verify per system)

- Warranty: 12 months (365 days) from shipment under normal use

- Traceability: Serial/part number recorded on delivery documents for maintenance records

Supporting Components & Accessories (commonly paired)

- ABB DSQC652 digital/analog I/O modules (for expanding field signals)

- Shielded fieldbus trunk/drop cables with proper termination resistors

- Panel hardware for secure mounting and cable strain relief inside the controller cabinet

Note: Fieldbus protocol and connector style on installed systems can vary by controller options. If you share your controller type and current I/O topology, we can double-check compatibility and ship the matching DSQC658 configuration.

Reviews

There are no reviews yet.