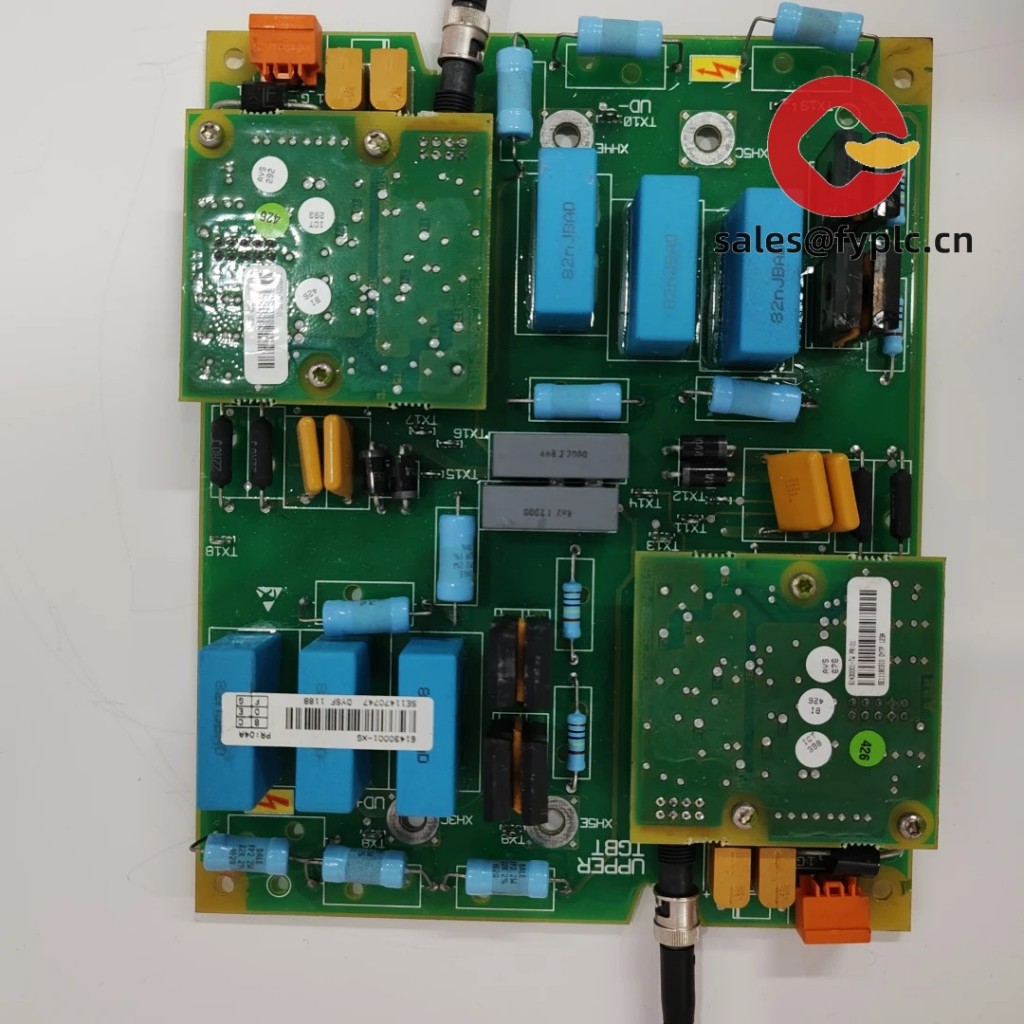

Description

ABB DTCC901B (61430001-FU) – Communication Controller Module for Advant/MB300 Networks

The ABB DTCC901B, order code 61430001-FU, is a communication controller module widely used in ABB Advant systems to interface controllers and I/O over MasterBus 300 (MB300). From my experience, it’s the piece you look for when an Advant node drops off the MB300 ring or when you’re restoring legacy connectivity without touching the rest of the cabinet. One thing I appreciate is the way it slots straight into the Advant subrack and pulls power from the backplane—no extra power wiring, typically no panel rework.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- MB300 network integration – Designed for ABB Advant nodes on MasterBus 300, commonly used in redundant control setups.

- Backplane-powered – Draws power from the Advant subrack; no separate external supply in most cases.

- Status diagnostics – Front-panel indicators help technicians spot link and module health at a glance.

- Form-fit-function replacement – Fits existing Advant subracks and cabling, minimizing downtime during swap-outs.

- Industrial robustness – Built for cabinet environments typically up to 55 °C with proper ventilation.

- Revision identification – Code “61430001-FU” helps match firmware/compatibility during maintenance planning.

Technical Specifications

| Brand / Model | ABB DTCC901B (Order code: 61430001-FU) |

| HS Code | 8538.90 (Parts for switching/control panels and apparatus) |

| Power Requirements | Powered via Advant system backplane; no external power supply required (typical backplane 5 VDC/24 VDC distribution within the rack). |

| Dimensions & Weight | Plug-in Eurocard for Advant subracks; approx. 6U height, ~160 mm depth; weight typically around 0.4–0.6 kg. |

| Operating Temperature | 0…+55 °C cabinet ambient recommended; non-condensing environment. |

| Signal I/O Types | Communication interfaces (no direct discrete/analog I/O); MB300 bus plus service/maintenance port depending on front panel variant. |

| Communication Interfaces | MasterBus 300 (MB300); service serial (RS‑232/RS‑485) may be available based on module revision and faceplate. |

| Installation Method | Plug-in module for ABB Advant subracks; rear backplane connector with front-panel retaining screws. |

Application Fields

Plants running ABB Advant/MB300 typically keep DTCC901B modules as essential spares. You’ll see them in:

- Pulp & paper lines using Advant Master nodes on MB300 rings

- Metals processing mills retaining legacy Advant I/O networks

- Power generation sites (boiler/turbine auxiliaries) with Advant DCS backbones

- Oil & gas and chemicals where MB300 is still the controller interconnect

One customer in a paper mill told us they swapped a DTCC901B during a planned 2‑hour maintenance window and had the MB300 node back up without touching the rest of the rack—which seems to be the most practical way to avoid long permits and re-qualification.

Advantages & Value

- Reliability – Purpose-built for Advant; proven stability on MB300 networks when matched to the correct revision.

- Compatibility – Form/fit/function replacement helps avoid re-engineering and keeps existing cabinet layout intact.

- Cost control – Extends life of installed assets; helps defer full-system migrations that often carry higher risk.

- Technical support – We can help verify revision alignment (61430001-FU) against your node configuration files before shipment.

Installation & Maintenance

- Cabinet & environment – Install in an ABB Advant subrack with proper grounding. Maintain clean, ventilated enclosures; keep ambient within 0…55 °C and avoid condensation.

- Wiring & shielding – Use the correct MB300 cabling and shielding practices; observe node address/jumper or DIP settings prior to replacement.

- Safety – Power down the rack segment unless your site procedure explicitly allows live replacement. Use ESD protection when handling the board.

- Commissioning – After install, verify MB300 ring health, node visibility, and any related diagnostics. Update maintenance logs with the -FU revision.

- Routine care – Periodically inspect connectors and backplane contacts; keep dust off the board surfaces. Firmware and configuration alignment should be checked during major turnarounds.

Quality & Certifications

- Original ABB hardware for industrial control use

- Typically CE-marked; UL recognition may apply depending on system/cabinet

- RoHS status can vary by vintage; replacement units are supplied to match project/site requirements

- Functional testing prior to shipment; 365-day warranty as stated above

If you share your existing node details or a photo of the current front plate, we can double-check the DTCC901B 61430001-FU against your configuration to avoid any mismatch. You might notice that this small step usually saves time during the outage.

Reviews

There are no reviews yet.