Description

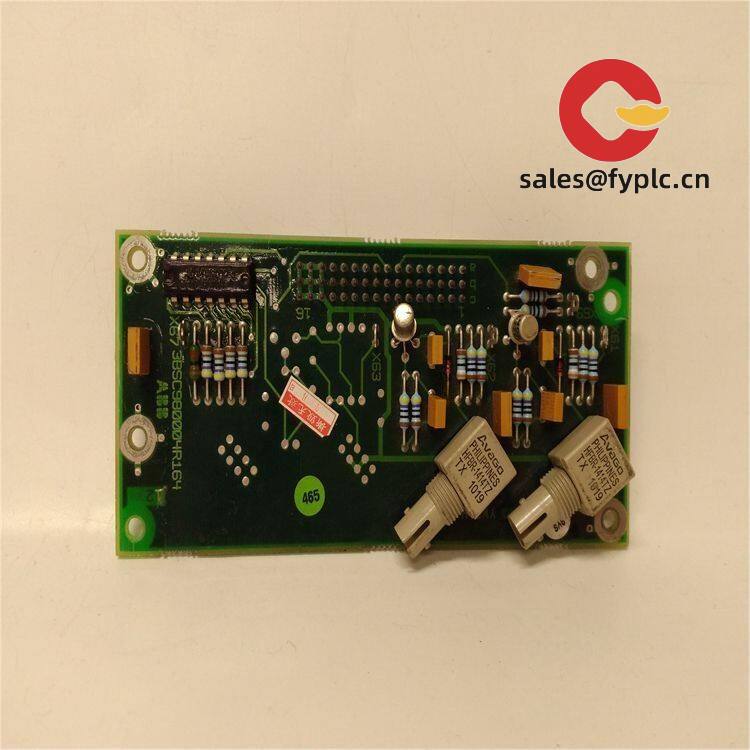

ABB DTDX991A (61430001-UW) – Digital I/O Termination Unit for Bailey INFI 90 / NET 90 Cabinets

The ABB DTDX991A, part number 61430001-UW, is a field-wiring termination board commonly used in ABB Bailey INFI 90 / NET 90 systems to bring discrete I/O signals cleanly into the DCS. From my experience, it’s the practical piece that makes cabinet marshalling straightforward—screw terminals on the field side, keyed ribbon/cable headers on the system side, and labelled rows that help technicians avoid mis-wires during tight shutdown windows. You might notice that the “UW” suffix typically denotes a conformal-coated variant, which in many cases offers better resistance to humidity and airborne contaminants in industrial environments.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock, no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- Dedicated INFI 90 / NET 90 termination – Provides a compatible field-wiring interface to ABB Bailey digital I/O modules, reducing marshalling time.

- Screw-terminal field side – Secure, clearly labeled terminal rows simplify installation and later maintenance checks.

- Ribbon/plug-in header to system – Typically mates to the I/O card/cable set, helping prevent pinout errors and speeding replacements.

- Conformal-coated variant (UW) – Usually better suited for cabinets with higher humidity or airborne dust.

- Service-friendly layout – Room for wire markers and channel notes; technicians can trace channels quickly during commissioning.

- Drop-in replacement – Fits standard marshalling practice in legacy ABB Bailey cabinets; no retraining for maintenance teams.

Technical Specifications

| Brand / Model | ABB DTDX991A |

| Part Number | 61430001-UW |

| System Compatibility | ABB Bailey INFI 90 / NET 90 digital I/O marshalling (termination board) |

| HS Code | 8538.90 (Parts for switching/protection apparatus) |

| Power Requirements | None (passive termination board) |

| Operating Temperature | Typically 0 to 60°C; 5–95% RH non-condensing (cabinet environment) |

| Signal I/O Types | Discrete (digital) field channels via screw terminals; system-side ribbon/plug connector |

| Communication Interfaces | Not applicable (termination only; no protocol processing) |

| Installation Method | Panel/cabinet mounting in marshalling area; connects to I/O module cable set |

Application Fields

Plants running ABB Bailey INFI 90 / NET 90 platforms—power generation, oil & gas, petrochem, pulp & paper, metals, water & wastewater—typically use the DTDX991A to terminate digital signals neatly in the cabinet. It’s especially handy for brownfield upgrades or card-for-card replacements where you want to keep the existing wiring plan and minimize downtime.

One thing I appreciate is how it keeps retrofit projects predictable: technicians can map legacy channel numbers straight across, avoiding middle-of-the-night rewires. A maintenance lead at a combined-cycle site told us, “Swapping the termination board with DTDX991A took under an hour; loop checks were the longer part, not the hardware.”

Advantages & Value

- Reliability – Robust terminals and coated board (UW variant) help withstand cabinet environments in most cases.

- Compatibility – Designed for ABB Bailey digital I/O marshalling; works with typical INFI 90 cabinet practices.

- Cost & Time Savings – Keeps existing wiring topology; reduces fat-finger errors and rework during outages.

- Supportability – Simple, passive hardware that’s easy to trace and replace; spares strategy is straightforward.

Installation & Maintenance

- Cabinet environment – Mount in a dry, ventilated cabinet; avoid direct moisture or corrosive gases. Keep ambient within typical 0–60°C.

- Wiring – Use correctly sized ferrules; torque terminal screws per standard practice; separate high-voltage from low-level signal wiring where applicable.

- Shielding & grounding – Land shields at designated earth points; avoid ground loops by following site grounding rules.

- Cable mating – Ensure ribbon/plug orientation matches the I/O card pinout; verify with the cabinet wiring diagram before power-up.

- Routine checks – Periodically re-torque terminals, inspect for dust build-up, and confirm channel labels match the as-built drawings.

Quality & Certifications

- Manufacturer quality system: ABB production typically aligned to ISO 9001 processes

- Compliance: CE marking is common for related ABB assemblies; UL recognition may apply at component level (varies by batch and region)

- RoHS status: May depend on production vintage for legacy Bailey parts; we can verify by part/lot on request

- Warranty: 365 days (advance replacement/support available depending on stock)

Reviews

There are no reviews yet.