Description

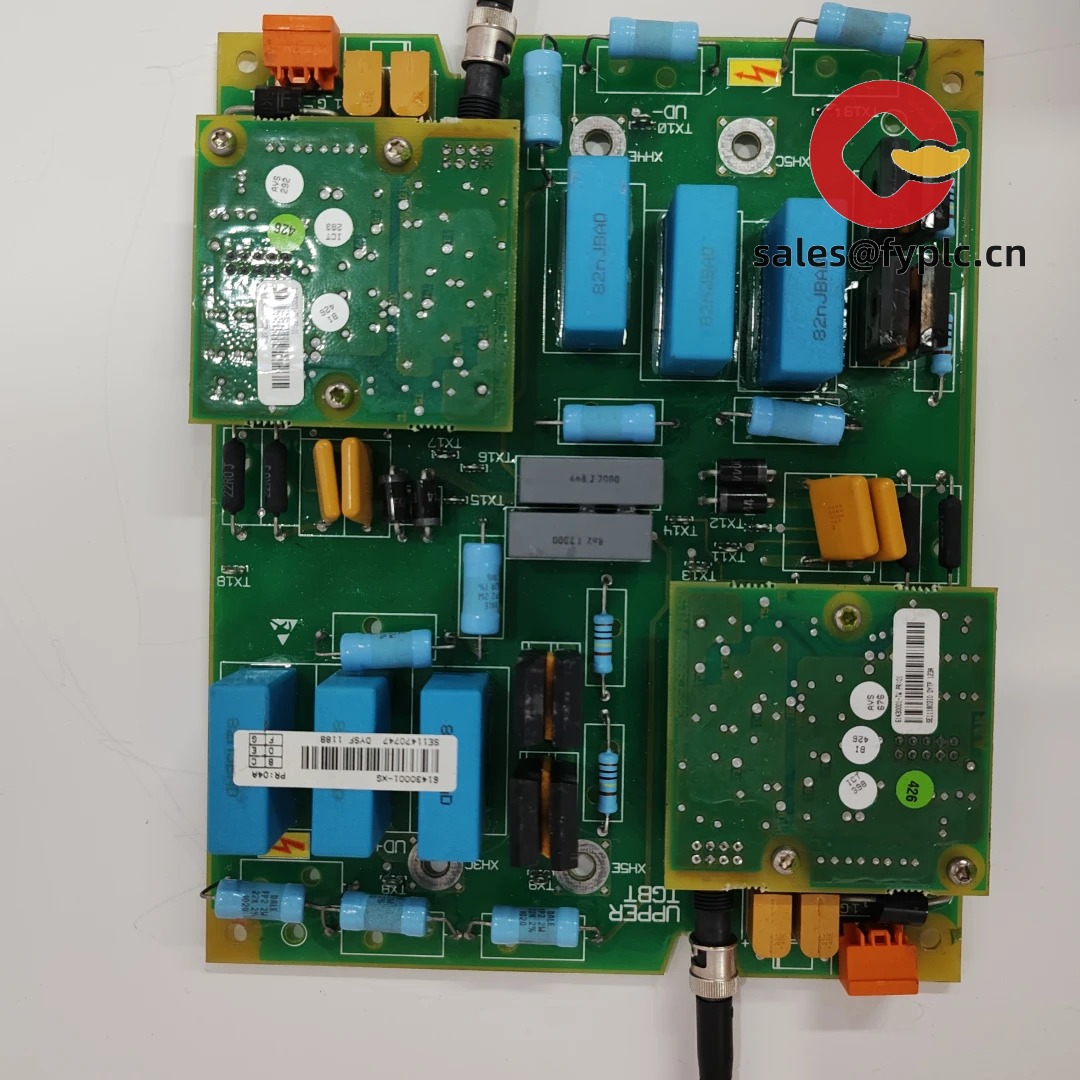

ABB DYSF118B (61430001-XG) – Control Interface Board for Installed ABB Drive/DCS Platforms

The ABB DYSF118B, marked with part code 61430001-XG, is a plug-in control/interface board used in ABB industrial drive and DCS environments as a form-fit-function module for existing installed bases. From my experience, this kind of DYSF-series board typically sits on a backplane, handling mixed signal conditioning and control interfacing between the host controller and field subsystems. If you’re maintaining legacy lines or planning a like-for-like replacement to keep downtime minimal, this unit is often the practical choice—no re-engineering, no surprises.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Process: Confirm model and quantity → Proforma invoice → Advance payment → Functional testing & packing → Shipment notification → Balance payment → Dispatch

Key Features

- Genuine ABB part, code 61430001-XG: Identical fit and interface for DYSF118B installations.

- Form-fit-function replacement: Keeps existing cabinet layout, wiring, and backplane connections intact.

- Backplane-powered design: Typically powered from the host system backplane, minimizing field wiring changes.

- Industry service range: In most cases suitable for cabinet ambients around 0–55°C when properly ventilated.

- Field-replaceable: Designed for quick swap-outs during scheduled stops to cut downtime.

- Lifecycle support: Stable availability for maintenance, retrofit, and spares strategies.

Technical Specifications

| Brand / Model | ABB DYSF118B (61430001-XG) |

| HS Code | 8538.90 (Parts for switching/protection/control apparatus) |

| Power Requirements | Typically 24 VDC supplied via system backplane (variant/system dependent) |

| Operating Temperature | Approx. 0 to 55°C cabinet ambient, non-condensing (typical for rack-mounted modules) |

| Signal I/O Types | Mixed control/interface signals routed through the backplane; channel specifics depend on system use |

| Communication Interfaces | Backplane bus interface to host controller (no external fieldbus on the board itself in most cases) |

| Installation Method | Plug-in rack module; secured by card guides/screws; powered and interfaced via backplane connector |

| Dimensions & Weight | Standard DYSF-series board footprint for ABB racks (contact us for exact panel fit if needed) |

Application Fields

You’ll typically see the DYSF118B in mature ABB drive or DCS cabinets across heavy industry—steel and metals lines, paper machines, mining conveyors, power generation auxiliaries, and marine propulsion support systems. One thing I appreciate is how it lets maintenance teams keep legacy controls stable while planning phased upgrades, instead of rushing a wholesale migration.

Advantages & Value

- Reliability: Known, predictable behavior in existing ABB ecosystems—ideal for regulated environments.

- Compatibility: Drop-in replacement minimizes engineering changes and revalidation work.

- Cost Control: Keeps the main system running without the cost of full controller replacement.

- Technical Support: We can assist with part matching by code/REV and do pre-shipment functional checks.

Installation & Maintenance

- Environment: Install in a closed control cabinet with adequate ventilation; maintain cabinet ambient typically within 0–55°C and <85% RH non‑condensing.

- Power-down replacement: De-energize, discharge residual energy, and follow ESD precautions. The board is not generally hot‑swappable.

- Seating & connectors: Inspect the backplane connector for dust/oxidation; seat the card fully and secure with screws or latches.

- Wiring practices: Keep control wiring segregated from power cabling; verify grounding and shield terminations per the original ABB cabinet design.

- Routine care: Quarterly dust removal with dry air (low pressure), check for loose fasteners, and record board IDs/REV for asset tracking. Firmware or parameter alignment should match the host controller’s requirements, where applicable.

Quality & Certifications

- Manufactured under ABB quality systems (ISO 9001 at time of production in most cases)

- Typically conforms to CE requirements for industrial control equipment when installed in the intended ABB system

- RoHS/UL status depends on production lot and year; we can verify by serial/REV before shipment

- Each unit supplied is function-tested before dispatch; 365-day warranty applies

Reviews

There are no reviews yet.