Description

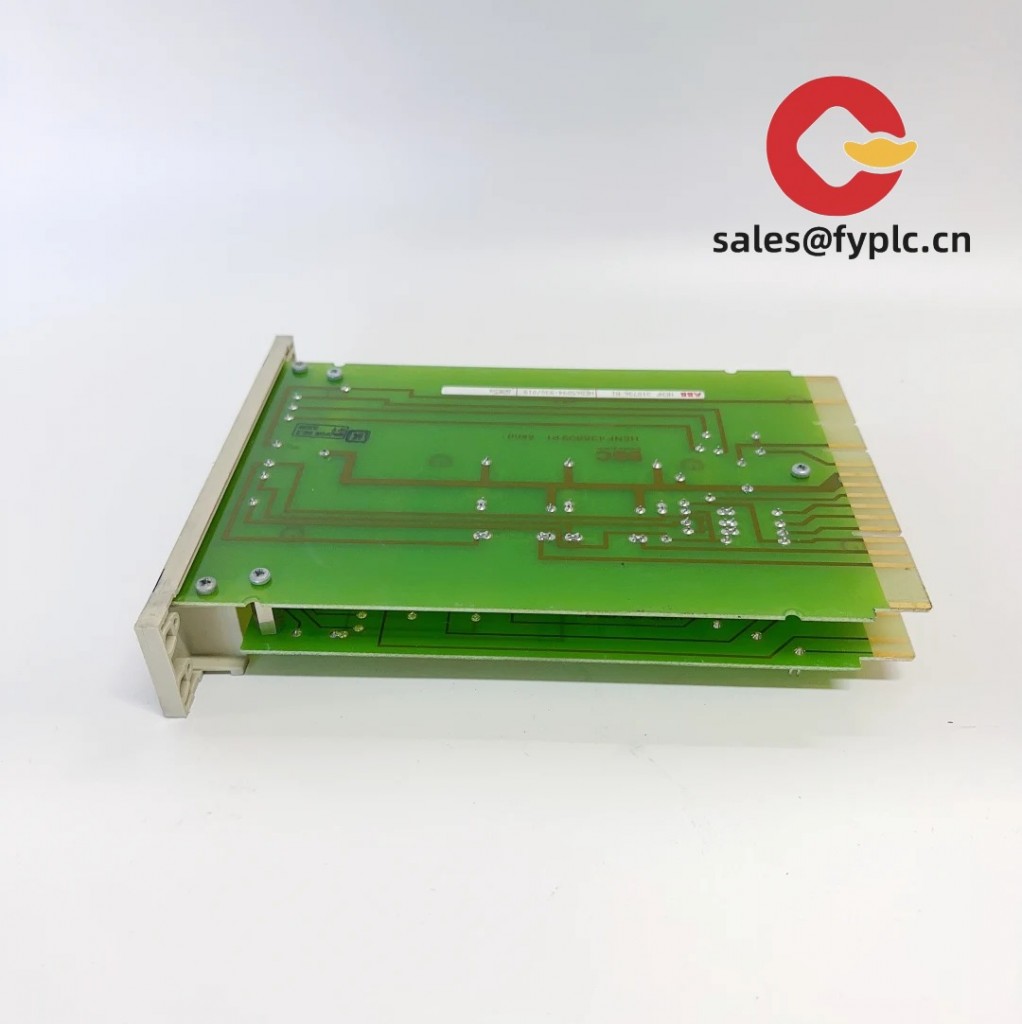

ABB EI812F (3BDH000021R1) – Ethernet interface module for Freelance AC 800F control systems

The ABB EI812F is an Ethernet interface module that typically serves as the network bridge for ABB Freelance AC 800F-based systems. From my experience, it’s the piece you add when you want reliable controller-to-plant network connectivity for HMI/SCADA access, engineering tools, and controller integration without overcomplicating the cabinet. It seems to be a favored choice in brownfield upgrades where stable TCP/IP connectivity and long-term availability matter more than flashy specs.

Company Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: In-stock items typically ship within 1 week; no more than 1 month at the latest

- Payment: 50% advance payment; full balance prior to delivery

- Express Options: FedEx, UPS, DHL

Key Features

- Purpose-built for ABB Freelance AC 800F: Designed to integrate cleanly with AC 800F controllers for stable TCP/IP networking in distributed control setups.

- Industrial Ethernet connectivity: Provides 10/100Base‑TX over RJ45 for controller networking, engineering access, and SCADA/HMI communication.

- Backplane-powered simplicity: Power is supplied via the system backplane, so wiring stays tidy and commissioning is quicker.

- Status diagnostics: Front-panel LEDs make it easy to verify link, activity and module status during FAT or onsite troubleshooting.

- Cabinet-friendly design: Compact module footprint that fits standard AC 800F baseplate installations and typical 600/800 mm control cabinets.

- Lifecycle stability: In many cases, the EI812F is chosen for its predictable behavior with stable firmware and broad ABB ecosystem compatibility.

Technical Specifications

| Brand / Model | ABB EI812F (Part No. 3BDH000021R1) |

| HS Code | 8537.10 (Programmable controllers / control panels – indicative for PLC communication modules) |

| Power Requirements | 24 V DC nominal via system backplane (typical for AC 800F modules) |

| Operating Temperature | 0 to +55 °C (typical control cabinet environment) |

| Signal I/O Types | Industrial Ethernet 10/100Base‑TX over RJ45 |

| Communication Interfaces | TCP/IP for AC 800F system/engineering connectivity; protocol use (e.g., SCADA/HMI access) depends on Freelance configuration |

| Installation Method | Mounted on AC 800F baseplate in a grounded control cabinet; front-access RJ45 |

Application Fields

You might notice the EI812F used wherever an ABB Freelance AC 800F controller needs a dependable Ethernet gateway:

- Process industries: chemicals, pharmaceuticals, food & beverage – controller-to-SCADA links and historian access

- Power & utilities: balance-of-plant networking, turbine auxiliary systems, water treatment skids

- Oil & gas: packaged skids and compressor stations needing secure engineering connectivity

- Metals, pulp & paper: line control, machine sections, and integration into site networks

Advantages & Value

- Reliability: Stable behavior with ABB Freelance makes factory acceptance and site commissioning more predictable.

- Compatibility: Works within the AC 800F ecosystem, reducing integration risk and avoiding one-off gateways.

- Cost control: Backplane power and straightforward wiring typically cut installation time and spare-parts overhead.

- Supportability: Access to ABB documentation and global service channels; firmware alignment with common Freelance versions.

Customer feedback (real-world use): “After swapping in the EI812F, our engineering tool connected first time and HMI tags came online without rework. We’ve left it untouched since—just routine checks.”

Installation & Maintenance

- Cabinet & grounding: Install in a clean, dry control cabinet with proper PE bonding. Maintain ventilation and keep ambient below 55 °C.

- Wiring: Use shielded CAT5e/CAT6 for RJ45 runs; separate from high-voltage or VFD cables. Observe minimum bend radius and label both ends.

- Network design: Assign fixed IPs per site standards; segregate control and office traffic (VLANs) where applicable. Avoid unmanaged daisy chains.

- Firmware alignment: Match module firmware with your Freelance/AC 800F version. From my experience, upgrading controller first then I/O/comm modules reduces downtime.

- ESD & handling: Observe ESD precautions when inserting/removing from the baseplate. Power down according to site MOC procedures.

- Routine maintenance: Quarterly check link/activity LEDs, inspect RJ45 connectors, clean dust with dry air, and review system event logs. Keep one spare module on hand for critical loops.

Quality & Certifications

- Certifications: CE and RoHS compliance are typical for this series; some batches may carry UL/cUL. Verify the exact markings on the nameplate for your unit.

- Manufacturer warranty: Standard ABB manufacturer terms apply; our supply warranty is 365 days.

Related/Supporting Components (typical in projects)

- ABB AC 800F controller main module (PM-series for Freelance)

- AC 800F baseplate and power module

- S800 I/O modules for field signals (AI, AO, DI, DO) where required

- Industrial Ethernet switches (managed), patch panels, cabinet accessories

Reviews

There are no reviews yet.