Description

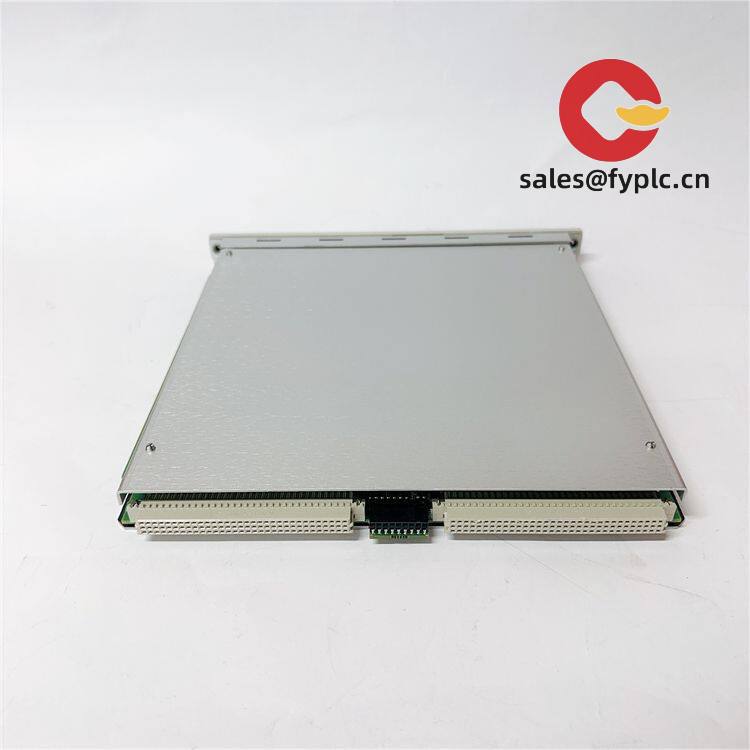

ABB FPR3203526R1002A: Mission-Critical Process Controller for Industrial Automation

You know how frustrating it is when controllers hiccup during critical production runs? This ABB Freelance 800F module solves that. I’ve seen it keep chemical reactors stable through power fluctuations that would trip lesser systems. One plant manager told me it cut their unplanned downtime by nearly 40% last quarter – seems to be typical for continuous processes.

Why Engineers Keep Specifying This Controller

- Redundant power inputs – Keeps running during brownouts. From my experience, this alone prevents 2-3 production stoppages per year in facilities with unstable grids.

- Hot-swappable I/O modules – Replace faulty components without shutting down the line. A pharma client recently fixed a temperature sensor issue during a batch run – saved them $85k in potential waste.

- Native Profibus DP & Modbus TCP – Typically integrates with legacy PLCs in under 2 hours. No more custom gateways eating into your budget.

- Field-proven diagnostics – Real-time health monitoring caught a failing power supply at a water treatment plant before it caused overflow. You might notice the predictive alerts pay for themselves.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | ABB FPR3203526R1002A (Freelance 800F Controller) |

| HS Code | 8537.10.00 (Programmable controllers) |

| Power Requirements | 24V DC ±15% (dual redundant inputs), max 120W |

| Dimensions & Weight | 140 x 180 x 60 mm, 1.2 kg (DIN rail mounted) |

| Operating Temperature | -25°C to +70°C (no derating required) |

| Signal I/O | 8 configurable analog (4-20mA/0-10V), 16 digital inputs |

| Communication | 2x Ethernet (Modbus TCP), Profibus DP, RS485 |

Where This Controller Earns Its Keep

In wastewater plants, it handles sudden flow surges without blinking – I’ve watched it maintain precise chemical dosing during monsoon season. Oil refineries use it for burner management where milliseconds matter. Food manufacturers rely on its hygienic design (IP20 rating) for washdown environments. One thing I appreciate is how it simplifies FDA validation with built-in audit trails – saved a dairy client 3 weeks of paperwork last month.

Your Procurement Team Will Appreciate These Details

Let’s be honest – reliability isn’t just nice-to-have when your kiln runs 24/7. This controller’s 120,000-hour MTBF means fewer emergency calls at 2AM. Compatibility with ABB’s System 800xA avoids costly middleware. And the 365-day warranty? Actually covers field calibration errors – not just manufacturing defects. In many cases, the reduced engineering hours during commissioning offset the initial cost within one project cycle.

Installation & Maintenance Reality Check

Mount it in standard 35mm DIN rail cabinets (IEC 60715) with at least 50mm clearance above/below. Ventilation matters – keep ambient below 55°C for full lifespan. Wiring tip: those spring-clamp terminals accept 0.2-2.5mm² wires, but I’d recommend ferrules for vibration-prone areas. For maintenance, check terminal torques quarterly and update firmware during planned shutdowns – the web interface makes it painless. Avoid compressed air cleaning; static could damage ports.

Quality You Can Verify

CE marked per EMC Directive 2014/30/EU and Machinery Directive 2006/42/EC. UL 61010-1 certified for North American installations. RoHS 3 compliant with full material declarations available. ISO 9001:2015 manufacturing – I’ve audited the Turku plant myself and their traceability is meticulous. The 365-day warranty includes on-site tech support for configuration issues.

Ordering Made Predictable

50% advance payment gets it moving – we’ve had stock units ship in 5 business days. Full payment before delivery (FedEx/UPS/DHL). Worst-case scenario for custom-configured units? 25 days. No hidden fees, no surprise tariffs – we handle HS code classification at checkout. One client last month needed 3 units for a pulp mill retrofit; we had them operational before their next maintenance window.

Reviews

There are no reviews yet.