Description

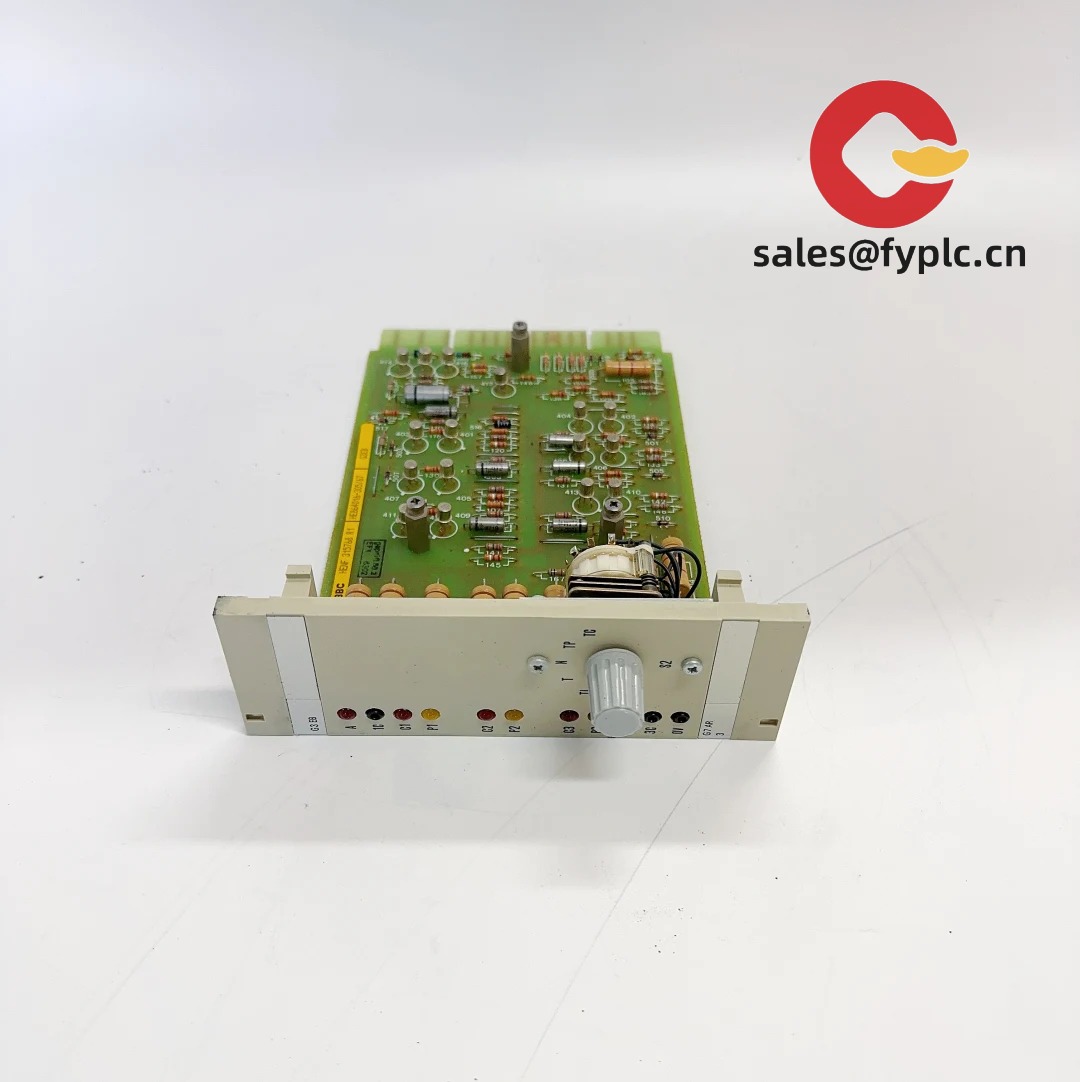

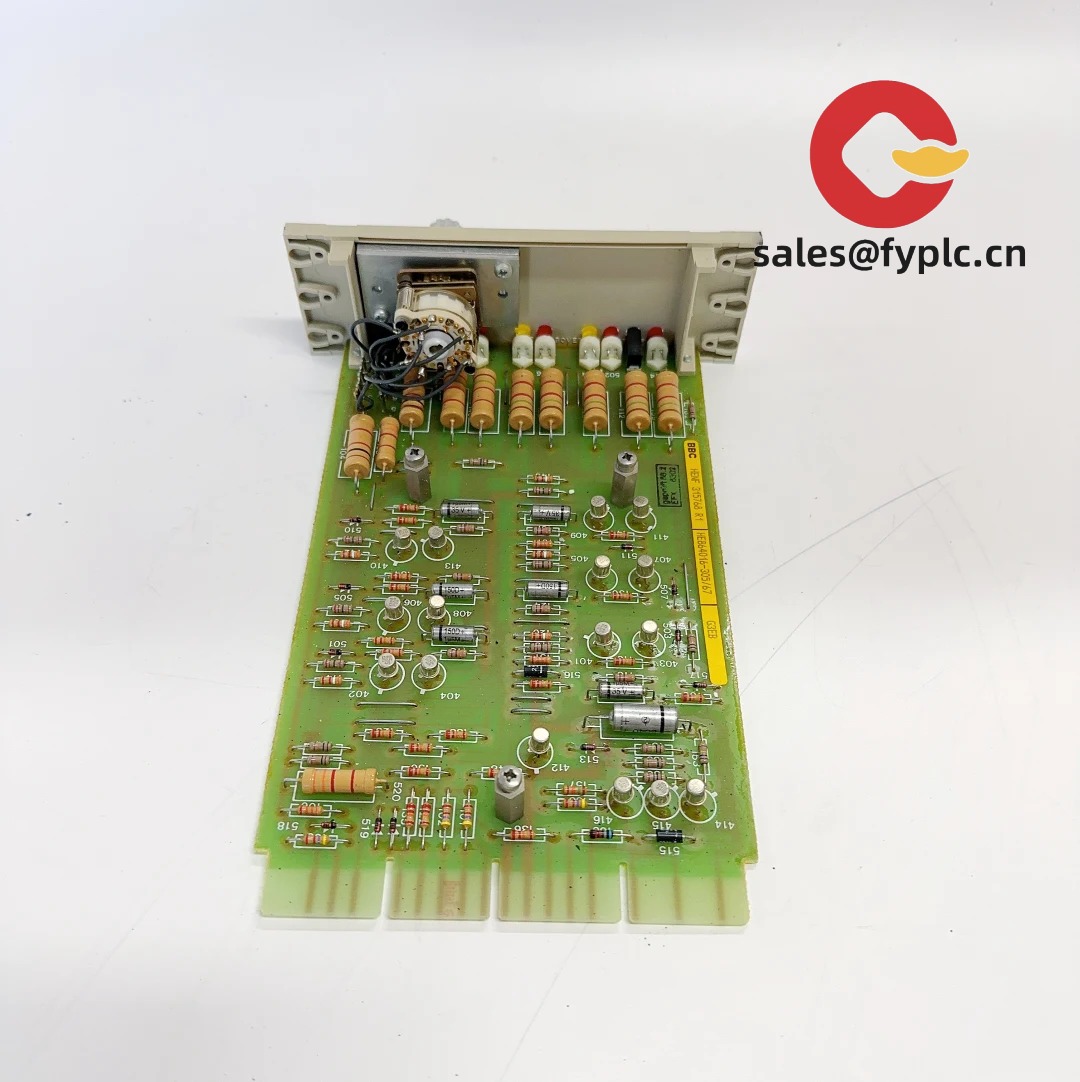

ABB G3EB HENF315768R1 – High‑performance industrial control module for ABB DCS/automation systems

The G3EB HENF315768R1 appears to be an ABB spare-module designation used in higher-end industrial control environments—typically found in ABB distributed control systems where reliability and long-term availability matter. From my experience, G-series/HENF-coded boards are engineered for rugged operation inside control cabinets, handling deterministic control and communication tasks on the system backplane. If you’re maintaining legacy or mixed-generation ABB platforms, this module usually slots in as a direct replacement with no change to the field wiring, which saves real downtime.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In-stock items ship in about 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Backplane-integrated design: Interfaces directly with the ABB system bus for low-latency control and diagnostics.

- Stable operation in industrial temps: Typically designed for 0–55°C cabinet environments used in plants.

- Drop-in service replacement: Maintains wiring and configuration in most cases, minimizing shutdown time.

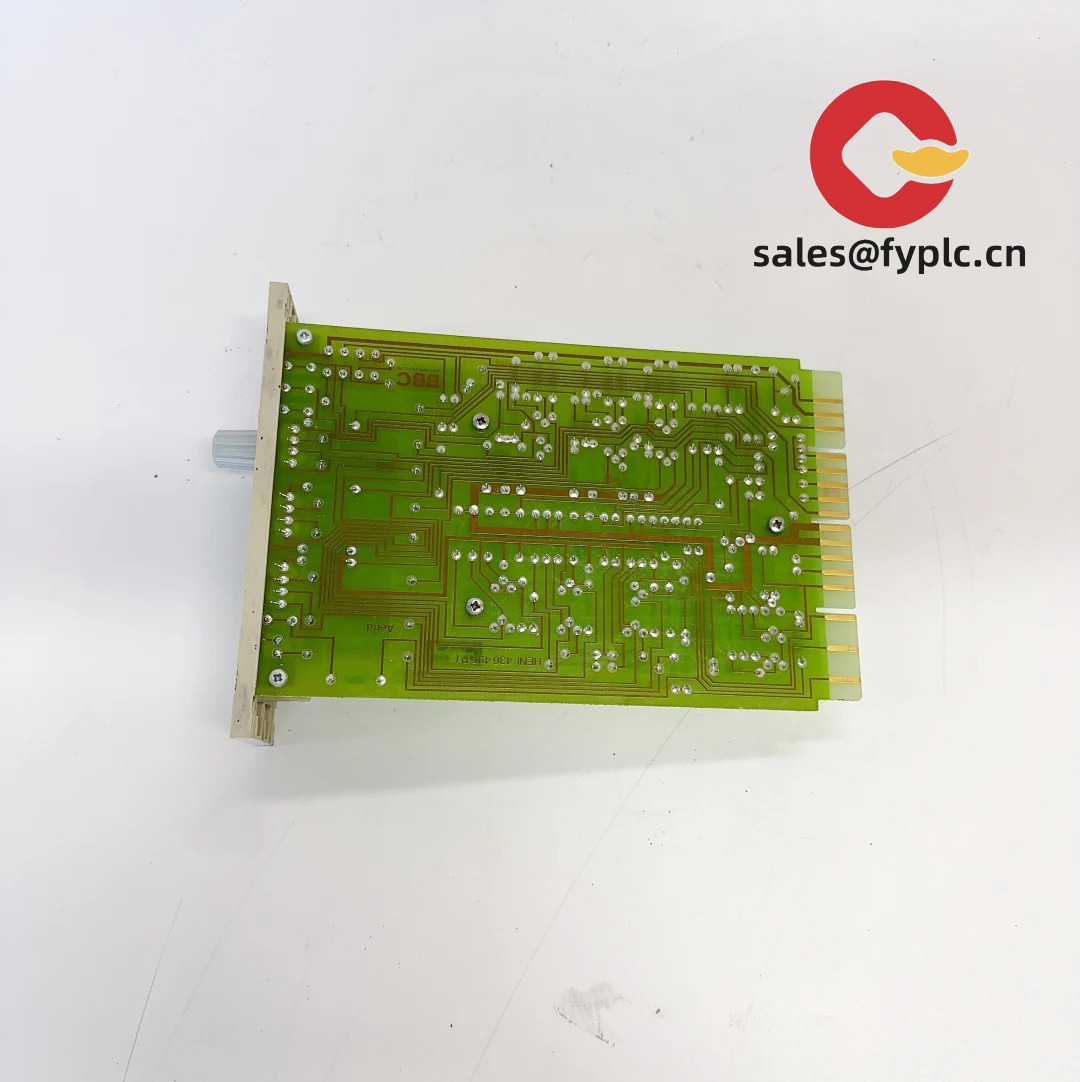

- Rugged build quality: Conformal-coated PCB and robust connectors are common on this class of ABB module.

- Predictable lifecycle support: ABB spare part coding (HENF…R1) makes revision tracking and maintenance planning straightforward.

- Service-friendly handling: Module/board form factor seems to be compatible with standard ABB chassis and extraction tools.

Technical Specifications

| Brand / Model | ABB / G3EB HENF315768R1 (Rev. R1) |

| HS Code | 8538.90 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Backplane-supplied DC power (no external PSU required, typical for ABB rack modules) |

| Operating Temperature | 0 to +55°C (typical cabinet ambient for ABB control modules) |

| Signal I/O Types | System-side via ABB backplane bus; field-side via front connector/terminal (channel type depends on the installed function) |

| Communication Interfaces | Integrated backplane communication to host controller/DCS node |

| Installation Method | Rack/chassis-mounted module; tool-assisted extraction/insertion recommended |

| Dimensions & Weight | Compact module format; typical ABB card footprint (exact values may vary by chassis) |

Application Fields

Plants running ABB DCS/automation platforms where deterministic control and high uptime are non-negotiable. You’ll commonly see modules like the G3EB HENF315768R1 in:

- Refining and petrochemical units (interlocks, sequence control, unit supervision)

- Power generation (boiler controls, BOP I/O, turbine auxiliaries)

- Pulp & paper (machine section controls, drives coordination)

- Metals & mining (process I/O concentration, line monitoring)

- Water & wastewater (plantwide I/O integration, redundancy nodes)

Advantages & Value

- Reliability under load: These ABB-coded boards tend to run for years in harsh cabinets with minimal drift.

- Form-fit-function compatibility: In many cases you avoid rewiring or re-validating loops—faster maintenance windows.

- Cost control: Extending the life of your installed ABB base is often more economical than fast-tracking a system migration.

- Technical support: We provide revision checks against HENF…R1 codes and help verify slot compatibility before shipment.

Installation & Maintenance

- Cabinet standards: Install in a clean, dry, ventilated control cabinet; maintain 0–55°C ambient and avoid vibration hot spots.

- ESD protection: Use grounded wrist straps and antistatic bags when handling; avoid touching component surfaces.

- Wiring & seating: Power down the rack (unless the slot is explicitly hot-swappable), check backplane connector alignment, then torque terminal screws evenly.

- Routine checks: Visually inspect connectors every shutdown cycle; clean dust with dry air; verify diagnostic LEDs after startup.

- Firmware/config: If the module carries firmware/config data, back up before replacement and verify version alignment with the host node.

- Calibration: For analog-related roles, confirm scaling and channel health after commissioning using plant standards.

Quality & Certifications

- Compliance: CE marking and RoHS conformity are typical for ABB control modules; some variants are UL recognized.

- Manufacturing standards: Produced under ISO 9001 quality systems (typical for ABB facilities).

- Warranty: 12 months (365 days) from delivery.

Common Accessories & Supporting Components

- ABB rack/chassis backplane: Provides DC power and system bus connectivity.

- Front terminal base/connector set: Field wiring interface; check pinout by module revision.

- Shielded field cables: Recommended for noise-prone zones around VFDs or heavy MCCs.

- Extraction tool/handle kit: Helps prevent connector damage during service.

Customer note: “We swapped in the G3EB-coded spare during a weekend stop. No rewiring, just seating and system check—line was back in under two hours.”

Reviews

There are no reviews yet.