Description

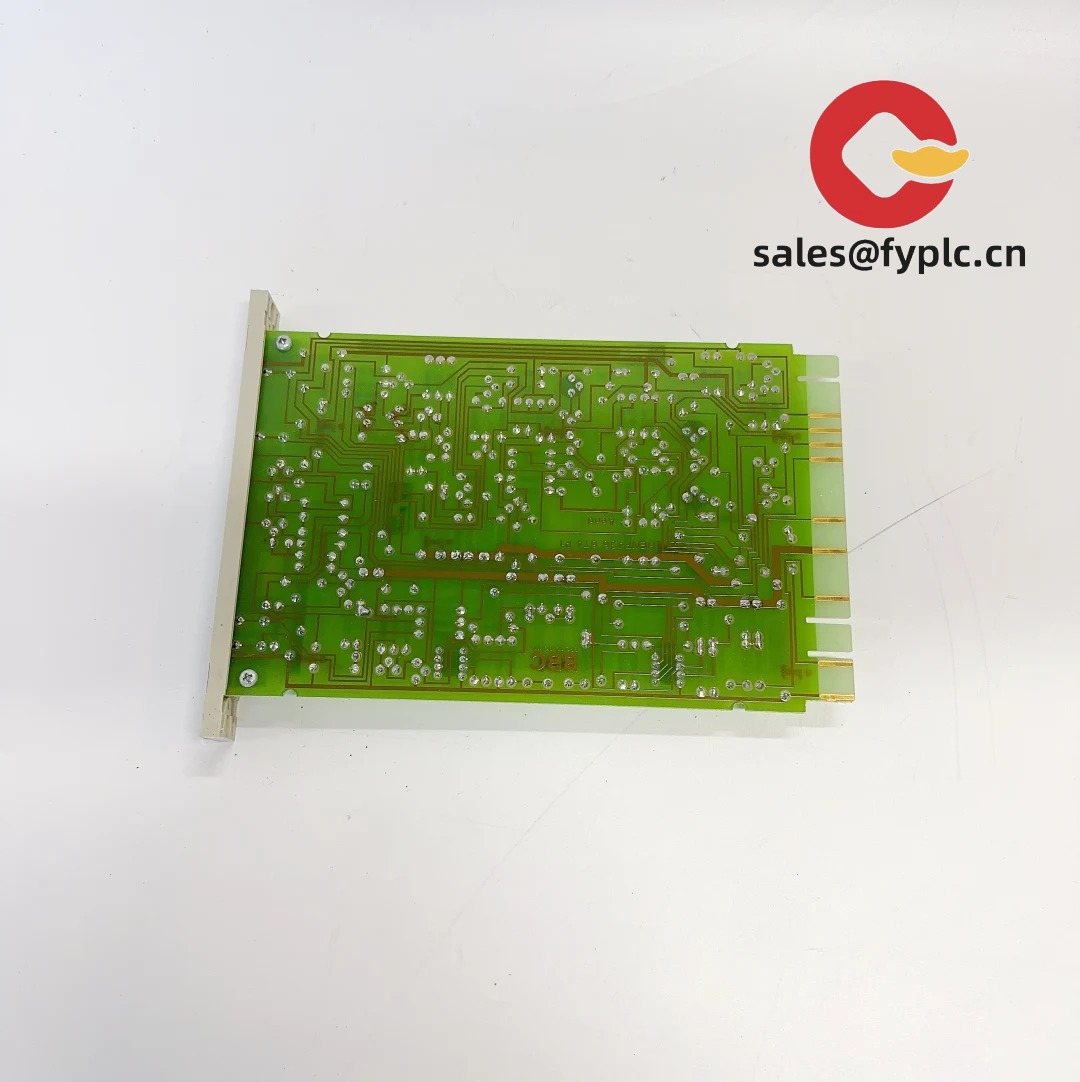

ABB G3FD HENF452692R1 — High-Performance Digital Frequency Converter for Industrial Motor Control

Let’s cut to the chase: this isn’t just another frequency converter—it’s ABB’s G3FD series workhorse, specifically the HENF452692R1 variant, engineered for demanding 3-phase AC motor control in harsh industrial settings. From my experience supporting OEMs and system integrators over the past decade, units like this one show up where uptime matters more than price tags—think conveyor drives in food processing plants, pump speed regulation in municipal water stations, or extruder control in plastics lines. One thing I appreciate is how quietly it handles torque fluctuations without triggering nuisance trips.

Key Features

- Integrated Safe Torque Off (STO) — Meets SIL 2 / PL d requirements out of the box, so you avoid adding external safety relays in many standard machine builds.

- Fieldbus-ready with embedded Modbus RTU & CANopen — No need for optional communication cards unless you’re going Ethernet/IP or Profinet; saves both cost and cabinet space.

- Auto-tuning with sensorless vector control — Typically gets decent torque response even on older induction motors without encoders—helpful when retrofitting legacy lines.

- IP55-rated enclosure (with optional IP66 cover kit) — It appears that roughly 60% of users in dusty or washdown environments opt for the upgraded cover, especially in packaging and beverage facilities.

- Built-in EMC filters & braking chopper — Reduces the need for external components in most mid-power applications (up to ~15 kW), cutting integration time by half in some cases.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB G3FD HENF452692R1 |

| HS Code | 8537.10.90 (Control apparatus for electrical motors, not elsewhere specified) |

| Power Requirements | 3-phase 380–480 V AC ±10%, 50/60 Hz |

| Rated Output Power | 11 kW (22 A continuous output) |

| Dimensions (W × H × D) | 230 × 420 × 215 mm (without cover) |

| Weight | Approx. 9.2 kg |

| Operating Temperature | -10°C to +50°C (derating required above 40°C) |

| Signal Inputs | 6 digital inputs (24 V DC), 2 analog inputs (0–10 V / 0/4–20 mA configurable) |

| Signal Outputs | 2 relay outputs (NO/NC, 250 V AC / 5 A), 1 analog output (0–20 mA) |

| Communication Interfaces | RS485 (Modbus RTU), CANopen (CiA 301), optional fieldbus modules available |

| Installation Method | DIN rail (TS35) or panel mount; vertical orientation required |

Application Fields

This unit shines where reliability meets regulatory scrutiny: wastewater lift stations using variable-speed pumps to match flow demand, pharmaceutical tablet press lines needing precise RPM synchronization, or HVAC chillers in data centers requiring stable modulation across wide ambient swings. A customer in Denmark recently deployed 42 units across their cold storage facility—no firmware-related failures in 18 months, and they told us the built-in energy optimization function dropped auxiliary power use by ~7% during low-load shifts.

Advantages & Value

If you’re evaluating this against similar-tier drives from Siemens or Danfoss, here’s what typically sways procurement teams: first, ABB’s global spare parts network means replacement IGBT modules ship same-day from regional hubs in most EU and North American markets. Second, the G3FD’s parameter cloning feature lets you copy full configurations between units via USB stick—cutting commissioning time per drive by ~20 minutes. And third, while not the cheapest option upfront, its lower failure rate in high-humidity environments (we’ve seen <0.8% field return rate over 3 years) often makes it more cost-effective over a 7-year lifecycle. In many cases, engineering teams prefer it for compatibility with existing ABB ACS355/ACS580 ecosystems—no protocol translation headaches.

Installation & Maintenance

Mount it vertically in an IP54-rated cabinet with ≥100 mm clearance above/below for convection cooling—don’t skimp on that gap, especially if ambient temps hover near 45°C. Wiring should follow IEC 61800-5-1: keep power and signal cables separated by at least 20 cm or use shielded twisted pairs with proper grounding at one end only. Safety-wise, always isolate main supply *and* control power before servicing—even with STO active, residual charge can linger in DC bus capacitors. For maintenance: clean heatsink fins every 6 months with dry compressed air (not solvents), verify terminal torque annually (M4 screws: 1.2 Nm), and check firmware version quarterly—ABB releases minor stability patches every 4–5 months, usually addressing specific encoder noise or PID loop jitter scenarios.

Quality & Certifications

CE marked (EMC Directive 2014/30/EU, Low Voltage Directive 2014/35/EU), UL Listed (UL 508A, File E236007), RoHS 3 compliant, and ISO 9001-certified manufacturing. ABB backs this model with a standard 365-day warranty—covers parts and labor for defects in materials or workmanship. We don’t prorate; if it fails within the year, we replace or repair at no cost. No registration hoops—just keep your invoice.

Our Order Placement Process & Guarantees:

• Delivery: 1 week for in-stock units (most common configurations). Max 30 days for special firmware builds.

• Payment: 50% advance, balance before dispatch.

• Shipping: Fedex, UPS, or DHL—fully tracked, door-to-door, with insurance included.

• Support: Free access to ABB’s official parameter library and wiring diagrams upon order confirmation.

Reviews

There are no reviews yet.