Description

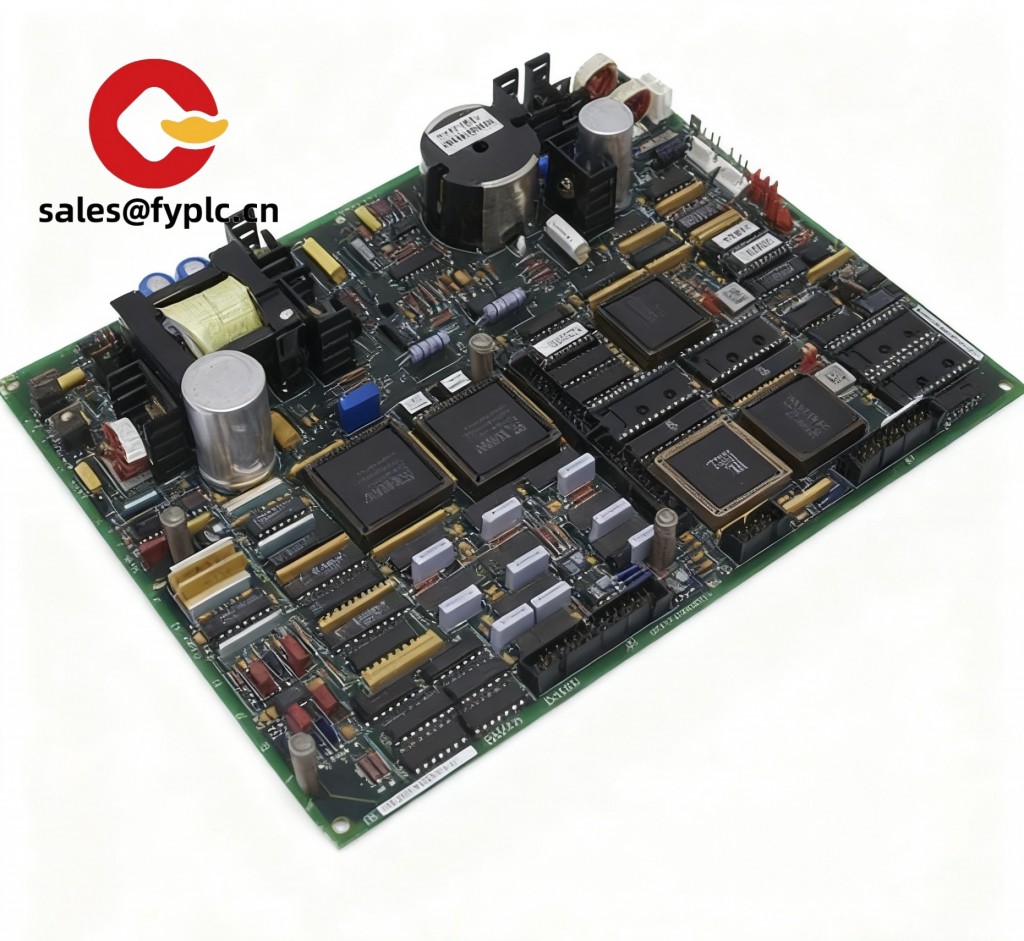

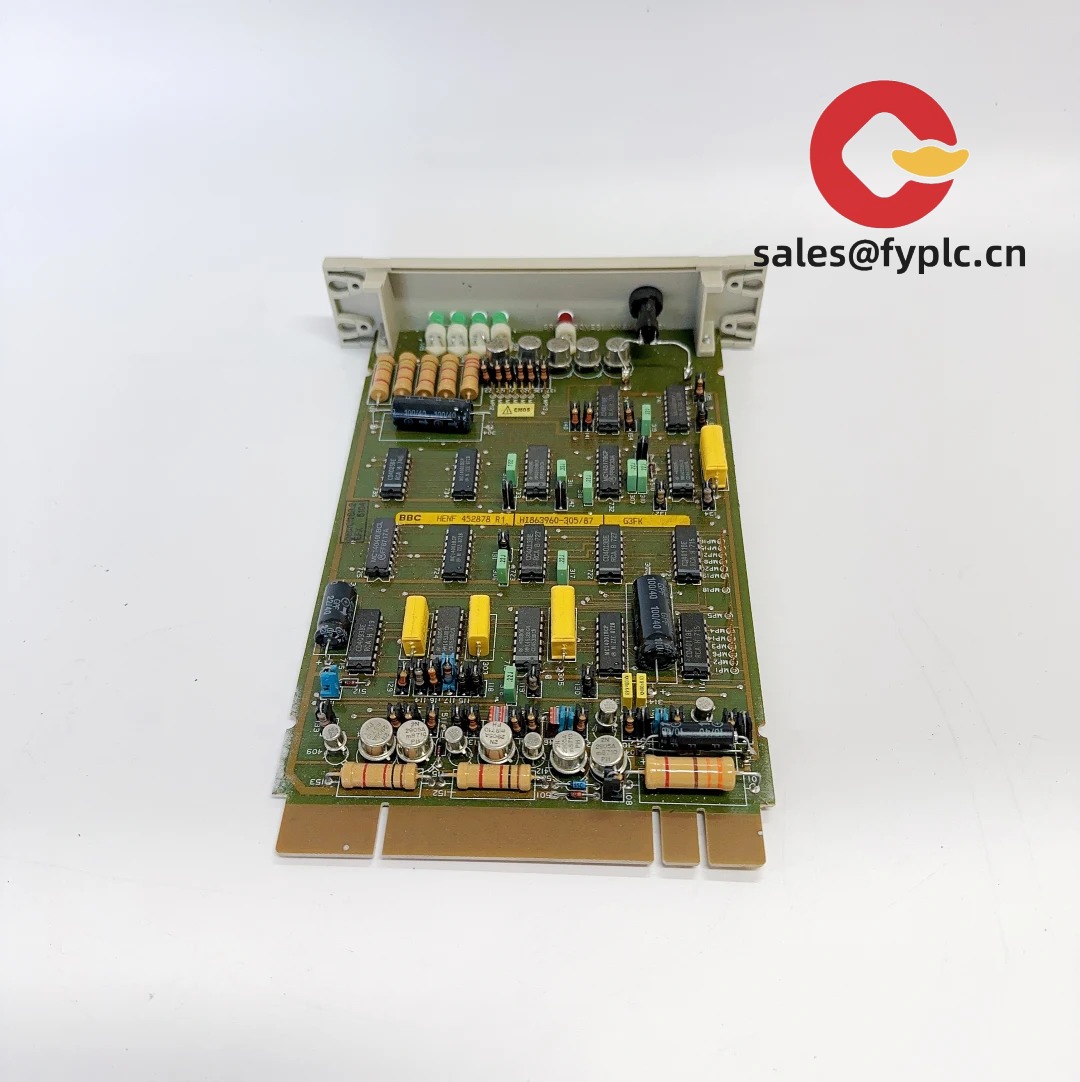

ABB G3FK HENF452878R1 Industrial Automation Control Module – Stable control and I/O interfacing for demanding plants

The G3FK HENF452878R1 is a robust control module commonly found in ABB drive and DCS-based installations, used as a main interface/controller within the G3FK family. From my experience, it’s selected as a dependable replacement unit or expansion module when you need stable control logic and consistent I/O handling without reworking the existing cabinet. You might notice that it integrates cleanly with backplane/rack assemblies and typically runs on a clean 24 VDC rail, which makes retrofits faster and less risky on live systems.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Backplane/Rack Integration: Drops into the designated G3FK slot for quick swap-outs, typically without rewiring field I/O.

- 24 VDC Operation: Standard industrial power input simplifies cabinet power design and redundancy.

- Stable Control Execution: Designed for continuous-duty plants where deterministic response and noise immunity really matter.

- Signal Flexibility: Supports mixed discrete and analog I/O when paired with the appropriate terminal base or interface board.

- Service-Friendly: Front-access connectors and a clear slot layout reduce downtime during planned maintenance.

- Lifecycle Fit: Ideal as a maintenance spare for legacy ABB-based systems still running critical lines.

Technical Specifications

| Brand / Model | ABB G3FK HENF452878R1 |

| HS Code | 8537.10 (Programmable controllers / control panels, subject to local customs classification) |

| Power Requirements | 24 VDC nominal (typically 18–30 VDC), power draw ≤ 10 W in most cases |

| Dimensions & Weight | Approx. 130 × 110 × 35 mm; ≈ 0.35 kg (module-only, without terminal base) |

| Operating Temperature | 0 to +55 °C, 5–95% RH non-condensing (typical for this series) |

| Signal I/O Types | Discrete 24 VDC and analog 4–20 mA / 0–10 V when used with compatible terminal/adapter boards |

| Communication Interfaces | Backplane system bus; service RS‑485; Ethernet availability depends on the specific hardware/firmware option |

| Installation Method | Rack/backplane mounting in the G3FK slot; DIN‑rail adapter kits used in some retrofits |

Application Fields

This module is typically deployed in continuous process and heavy industrial environments: metals and rolling mills, oil & gas flow control, power generation auxiliaries, marine propulsion and drives, pulp & paper sections, and municipal water treatment. A plant engineer at a steel mill told us the G3FK swap reduced downtime to a single shift because it slotted straight into the existing rack and picked up the configured I/O without surprises.

Advantages & Value

- Reliability in the field: Built for 24/7 service where trips and nuisance alarms cost real money.

- Compatibility-first approach: Works with established ABB backplanes and I/O bases, which often means no panel redesign.

- Lower change risk: Operators and maintenance techs keep their familiar workflow; fewer retraining steps.

- Cost control: Extends useful life of installed assets and defers full system migrations.

- Supportability: We can assist with pre-shipment testing and version checks to match your installed base.

Installation & Maintenance

- Cabinet environment: Use an IEC/NEMA-grade enclosure with proper ventilation. Keep ambient within 0–55 °C; avoid corrosive atmospheres.

- Power & grounding: Stable 24 VDC with upstream protection and proper earth bonding. Add surge suppression in noisy drive rooms.

- Wiring: Use shielded twisted pairs for analog signals. Route control and power separately to limit EMI.

- Handling: Observe ESD precautions when inserting/removing the module from the backplane.

- Routine checks: Quarterly visual inspection for loose connectors or dust; clean with dry air. Back up configuration/firmware after any change.

- Calibration: If analog loops are used, verify 4–20 mA scaling at commissioning and during planned shutdowns.

Quality & Certifications

- Typically compliant with CE and RoHS requirements for industrial control equipment

- UL/CSA recognition may apply depending on the complete system assembly

- Manufactured under ISO 9001 quality systems (vendor/manufacturer level)

- Warranty: 365 days from shipment

Commonly Paired Accessories (available on request)

- Backplane/rack units for the G3FK slot layout

- 24 VDC redundant power conditioners and surge suppression modules

- Terminal/adapter boards for discrete and analog I/O break-out

- Service cables for RS‑485 and maintenance ports

If you share the installed firmware revision or the rack configuration, we can pre-verify compatibility and stage a like-for-like unit. One thing I appreciate is how predictable this series is during changeovers—most teams complete the swap in a single maintenance window.

Reviews

There are no reviews yet.