Description

ABB GCC960C103 (3BHE033067R0103 / 3BHE033068P106) – Gate Control Card for ABB Medium-Voltage Drive Gate Units

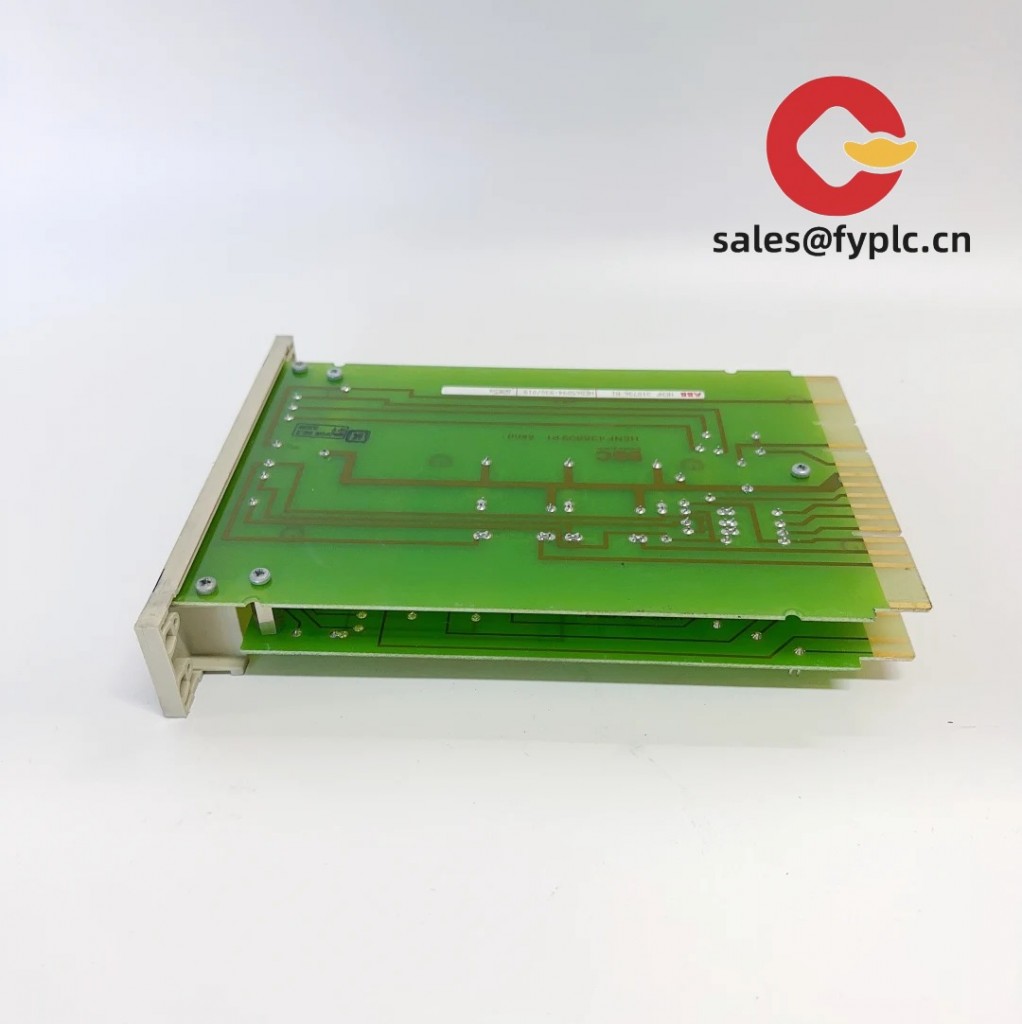

The ABB GCC960C103 is a gate control card typically used inside ABB medium-voltage drive gate units, providing reliable triggering and feedback handling for power semiconductors in IGCT-based systems. The part numbers 3BHE033067R0103 and 3BHE033068P106 are commonly associated with this board family, helping maintenance teams match the correct revision when replacing or expanding installed equipment. From my experience, this is a straight, form-fit-function replacement in most cases, designed to minimize commissioning time and get production back online quickly.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

To ensure revision-compatibility, share your drive type, gate unit type, and the existing board’s label (including the 3BHE code and revision). One thing I appreciate is how much downtime this avoids during switchover.

Key Features

- Form-fit-function replacement: Designed to drop into the existing ABB gate unit with minimal wiring changes.

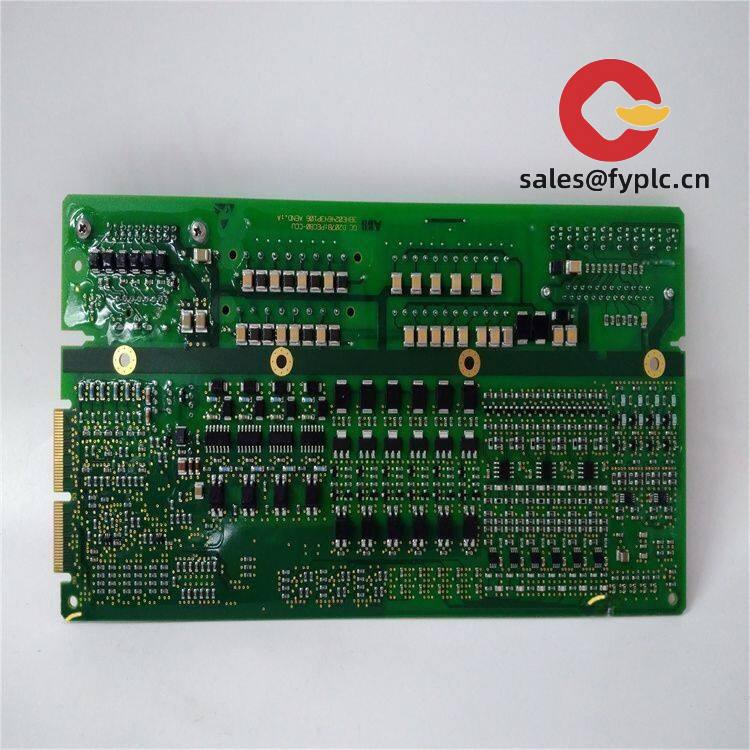

- Fiber-optic isolation: Typically uses optically isolated trigger/feedback channels to reduce noise and improve EMC in MV drive cabinets.

- Revision-tracked part numbers: 3BHE033067R0103 and 3BHE033068P106 help match the correct hardware/firmware generation.

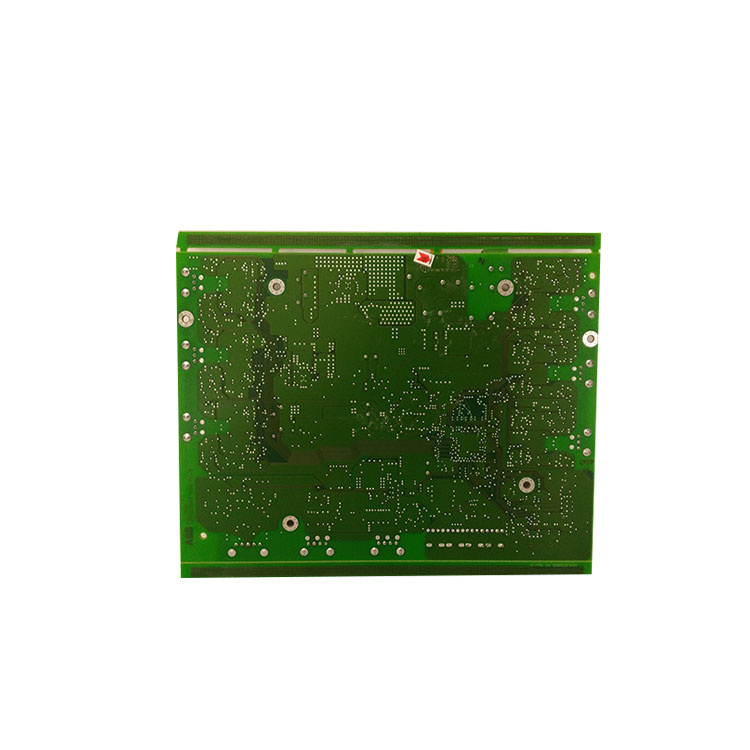

- Industrial reliability: Built for continuous-duty environments; in many cases conformally coated for humidity and dust resistance.

- Service-friendly: Clear labeling and keyed connectors for quicker replacement during planned shutdowns.

- Compatibility support: We can assist with cross-checking against your existing gate unit and drive build list.

Technical Specifications

| Brand / Model | ABB GCC960C103 (Associated P/N: 3BHE033067R0103 / 3BHE033068P106) |

| HS Code | 853890 (Parts for switching/protection or control apparatus) |

| Power Requirements | Supplied by host gate unit; typically low-voltage DC (commonly 24 VDC) |

| Operating Temperature | Typically 0 to +55 °C when installed in a ventilated control cabinet |

| Signal Input/Output Types | Fiber-optic trigger and feedback channels; low-voltage digital monitoring signals (as implemented by gate unit) |

| Communication Interfaces | Fiber optic links within ABB drive/gate unit architecture |

| Installation Method | Plug-in PCB inside ABB gate unit; secured via stand-offs/screws; ESD-safe handling required |

Note: Exact firmware/hardware pairing may vary by drive family and revision. A quick BOM check against your installed base avoids mismatch.

Application Fields

This board is commonly found in ABB medium-voltage drive systems used across cement mills, metals rolling lines, mining conveyors, oil & gas compressors, marine propulsion, and large water pumping stations. You might notice it specified wherever IGCT-based gate units are installed and fiber-optic triggering is required for high power stages.

Advantages & Value

- Reduced downtime: Drop-in spare that typically reuses existing wiring and connectors.

- Compatibility assurance: Part-number and revision matching (3BHE codes) improves the chance of plug-and-run success.

- Lifecycle support: Helps extend the service life of installed ABB MV drives without full panel retrofit.

- Cost control: Targeted board replacement is usually far more economical than replacing a full gate unit.

- Technical backing: We assist with pre-checks, packing, and functional test reports when available.

Installation & Maintenance

- Cabinet environment: Install in a clean, dry, ventilated control cabinet; avoid conductive dust and condensation.

- ESD & safety: Power down and lock-out the drive; use ESD wrist strap and antistatic mat when handling the board.

- Wiring & optics: Inspect fiber-optic connectors; keep bend radii gentle and connector ends clean.

- Firmware alignment: Match board revision/firmware to the gate unit and drive firmware where required.

- Routine checks: Periodically verify connector seating, clean dust with dry air, and confirm status LEDs/diagnostics during planned shutdowns.

Feedback from a metals plant maintenance lead: “Swapped the GCC960C103 during a 4‑hour window. Once the fiber pairs were seated and the interlocks cleared, the line was back at load without re-tuning.”

Quality & Certifications

- Manufacturer quality system: ABB production typically adheres to ISO 9001.

- Compliance: Components used in ABB drives commonly follow CE and RoHS requirements when integrated in the certified system.

- Warranty: 12 months (365 days) from delivery, covering manufacturing defects under normal use.

Reviews

There are no reviews yet.