Description

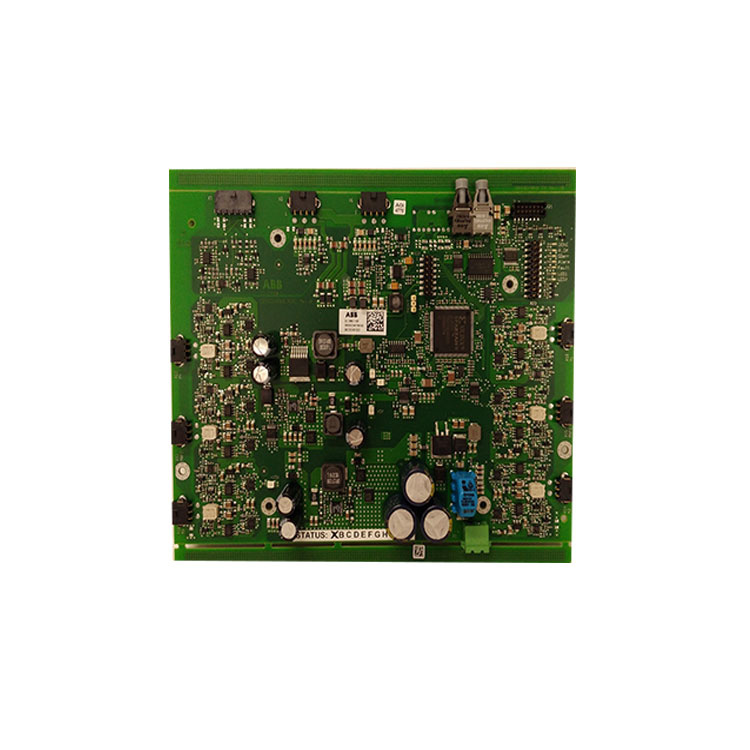

ABB GCD207B101 (3BHE024642R0101) – Gate Control/Driver Board for ABB High-Power Drive Systems

The ABB GCD207B101, part number 3BHE024642R0101, is a factory-grade gate control/driver board used inside ABB high-power inverter/rectifier cabinets. From my experience, this series is typically found in medium-voltage or large-frame low-voltage drives where reliable gate triggering and monitoring are essential for IGCT/IGBT power stacks. If you’re maintaining legacy or running critical assets on tight shutdown windows, this board keeps gate control precise and stable, which in many cases is the difference between a smooth restart and an unplanned stoppage.

Our Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Quality checks: Visual and functional checks prior to dispatch, anti-static packaging

Key Features

- Dedicated gate control – Provides stable triggering and feedback handling for high-power semiconductor stacks, improving drive reliability in demanding duty cycles.

- Fiber-optic signal paths – Typically uses fiber links for noise immunity and galvanic isolation inside the cabinet, which helps in high-EMI environments.

- Backplane integration – Designed to slot into ABB rack/backplane assemblies, simplifying swap-outs during maintenance.

- Service-friendly design – Clear connectors and keyed interfaces reduce installation errors; technicians can change it quickly during a short stop.

- Genuine ABB part mapping – Marked as GCD207B101 with ABB P/N 3BHE024642R0101 to match your BOM and cabinet documentation.

Technical Specifications

| Brand / Model | ABB GCD207B101 (3BHE024642R0101) |

| Functional Class | Gate control/driver board for ABB high-power drive cabinets |

| HS Code | 853890 (Parts for electrical apparatus of 8535/8536/8537) |

| Power Requirements | 24 VDC nominal, supplied by host drive (board-level consumption, low) |

| Operating Temperature | Typically 0…+55 °C (inside control cabinet) |

| Signal I/O Types | Fiber-optic gate/control links; isolated low-voltage logic/feedback lines (cabinet-internal) |

| Communication Interfaces | Proprietary ABB backplane connectors; fiber links within the drive system |

| Installation Method | Plug-in/rack-mounted PCB with captive screws; ESD-safe handling required |

Application Fields

You’ll typically see this board in heavy-duty applications where medium-voltage or large-frame drives run around the clock:

- Steel and metals (mill stands, coilers, ladle turrets)

- Cement and mining (kilns, crushers, conveyors, hoists)

- Power and water (pumps, fans, blowers with strict process uptime)

- Marine and oil & gas (thrusters, compressors, auxiliary drives in harsh environments)

A maintenance supervisor from a metals plant told us, “Swapping the GCD board was straightforward; once fiber seats were cleaned, the drive synced back without nuisance trips.” That seems to be the usual experience when good installation practice is followed.

Advantages & Value

- Reliability under load – Stable gate timing helps reduce device stress and unexpected trips, especially during high-torque starts.

- Form-fit replacement – One thing I appreciate is how ABB keeps the mechanical and electrical interfaces consistent, which shortens downtime.

- Lower lifecycle cost – Keeping the original drive engineering intact avoids costly retrofits and requalification.

- Technical backup – We can help verify firmware compatibility and board revisions to match your cabinet serial and drive frame.

Installation & Maintenance

- Environment: Install in a clean, dry control cabinet (IP54 or as specified by the drive), with adequate ventilation and filtered airflow.

- Power-off & ESD: Completely de-energize the drive, wait for DC link discharge, and use ESD protection (wrist strap, antistatic mat).

- Wiring & fibers: Inspect and clean fiber ends; avoid tight bends; verify connector keying and seating. Keep low-voltage harnesses away from high-EMI routes.

- Fastening: Use the designated mounting points and torque the captive screws evenly to ensure proper grounding and vibration resistance.

- Commissioning: After replacement, run manufacturer-recommended self-tests, check gate enable signals, and confirm interlocks and trips are normal.

- Routine care: Quarterly cabinet cleaning, connector inspection, and fiber cleanliness checks; firmware/parameter verification during planned outages.

Quality & Certifications

- Manufacturing system: Typically produced under ISO 9001 quality management

- Compliance: Used within CE-conforming drive assemblies; RoHS alignment is common for this class of board

- Traceability: Supplied with ABB part number 3BHE024642R0101 and standard labeling for lifecycle tracking

- Warranty: 12 months (365 days) replacement warranty from our side

You might notice that compatibility can vary by drive frame and revision. If you share the cabinet type or serial, we’ll double-check the GCD207B101 against your BOM so you receive a plug-in compatible board the first time.

Reviews

There are no reviews yet.