Description

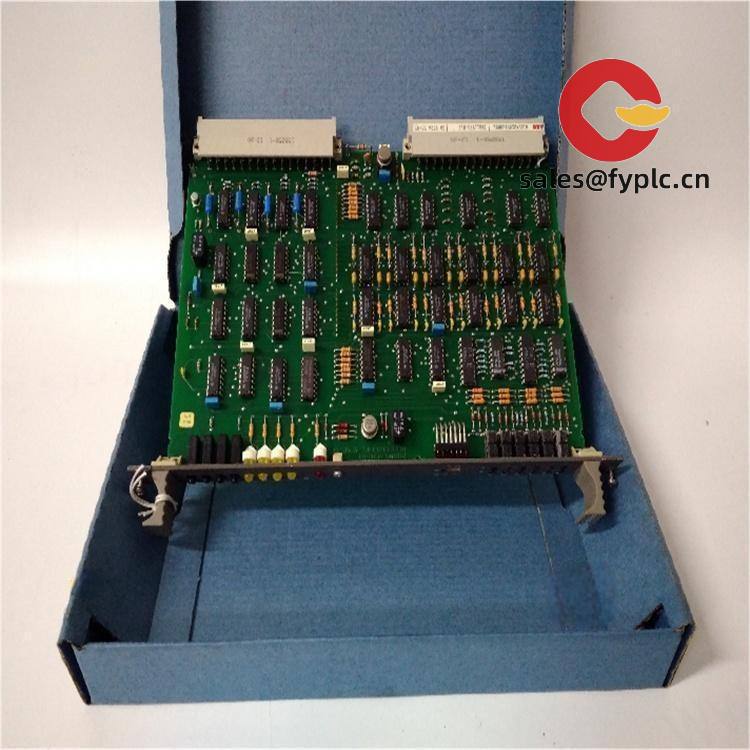

ABB GDC806A0101 (3BHE028761R0101) – Gate Drive Controller Board for High-Power/Medium-Voltage Drive Systems

The ABB GDC806A0101, also marked as GD C806 A0101 and traceable under part number 3BHE028761R0101, is a gate drive controller board used in ABB high-power converter stacks. In many cases, it sits between the main control and the IGCT/IGBT gate units, coordinating fiber‑optic firing commands, interlocks, and fault feedback. If you’re maintaining an ABB medium-voltage drive or a large industrial converter, this is typically the board that keeps the power stage synchronized and protected.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

From my experience, fast replacement of this board noticeably reduces downtime on MV drives. We typically help customers match firmware/hardware revisions so the unit integrates smoothly with the existing stack.

Key Features

- Gate drive coordination: Manages firing patterns and interlocks to the power devices through fiber‑optic channels.

- High isolation design: Fiber links and opto‑isolation reduce electrical noise coupling in high dV/dt environments.

- Real-time protection: Monitors feedback for desaturation/trip conditions and propagates fast shutdown commands.

- Backplane integration: Plug‑in connection to ABB control backplanes for compact routing and serviceability.

- Status diagnostics: On‑board indicators and signal test points make commissioning and fault tracing easier.

- Form-fit compatibility: Designed to fit ABB GDC8xx locations, helping maintenance teams swap boards quickly.

Technical Specifications

| Brand / Model | ABB GDC806A0101 (GD C806 A0101) / 3BHE028761R0101 |

| HS Code | 850490 (Parts for static converters, e.g., drive systems) |

| Power Requirements | 24 VDC nominal, low-power control electronics (typical cabinet supply) |

| Operating Temperature | 0 to +55 °C typical control cabinet conditions (non‑condensing) |

| Signal I/O Types | Fiber‑optic gate trigger/feedback channels; opto‑isolated digital signaling; local status LEDs and test points |

| Communication Interfaces | Backplane connector to main controller; fiber links to gate units; service/diagnostic headers (as per board revision) |

| Installation Method | Plug‑in PCB module for ABB drive cabinet; secured on rails/screws; ESD‑safe handling required |

| Form Factor | Board‑level assembly (GDC8xx footprint), lightweight, cabinet‑mounted |

Application Fields

You’ll typically find the GDC806A0101 in ABB medium‑voltage drives and large converters used in:

- Metals (rolling mills, roughing stands, process lines)

- Cement & mining (kilns, fans, conveyors, hoists)

- Oil & gas and chemicals (compressors, extruders, pumps)

- Marine & ports (thrusters, propulsion, crane drives)

- Power & utilities (test benches, excitation/converter systems)

One thing I appreciate is how this board streamlines fiber‑optic gating—installers often mention quicker commissioning when replacing like‑for‑like GDC8xx modules.

Advantages & Value

- Reliability: Purpose‑built for high‑energy power stages with noise‑immune signaling.

- Compatibility: Form‑fit board for ABB GDC8xx locations; supports common fiber‑optic gate units used in MV stacks.

- Cost control: Direct replacement reduces engineering time and limits unplanned downtime.

- Support: We can help check board revisions and fiber mapping so the swap is straightforward.

Installation & Maintenance

- Cabinet environment: Mount inside a clean, ventilated control cabinet; avoid condensation and corrosive atmospheres.

- Wiring/fibers: Keep fiber bend radius within spec; label TX/RX pairs; route away from high‑current busbars.

- Grounding & EMC: Verify cabinet bonding; maintain shield terminations per ABB layout to minimize noise.

- ESD & handling: Use grounded wrist straps and ESD mats; handle by edges only.

- Firmware/parameters: Match board revision and firmware to the drive controller; back up parameters before changeout.

- Routine care: Periodically clean dust with dry, oil‑free air; check connectors; review event logs after trips.

Quality & Certifications

- CE-compliant as part of the complete ABB drive system

- RoHS/REACH-aligned materials (typical for ABB control PCBs)

- Manufactured under ISO 9001 quality systems at the OEM level

- Warranty coverage: 365 days

Customer feedback (compressor line, EMEA): “Swap took less than an hour. Fiber mapping matched our existing gate units and the drive was back online the same shift.”

Reviews

There are no reviews yet.