Description

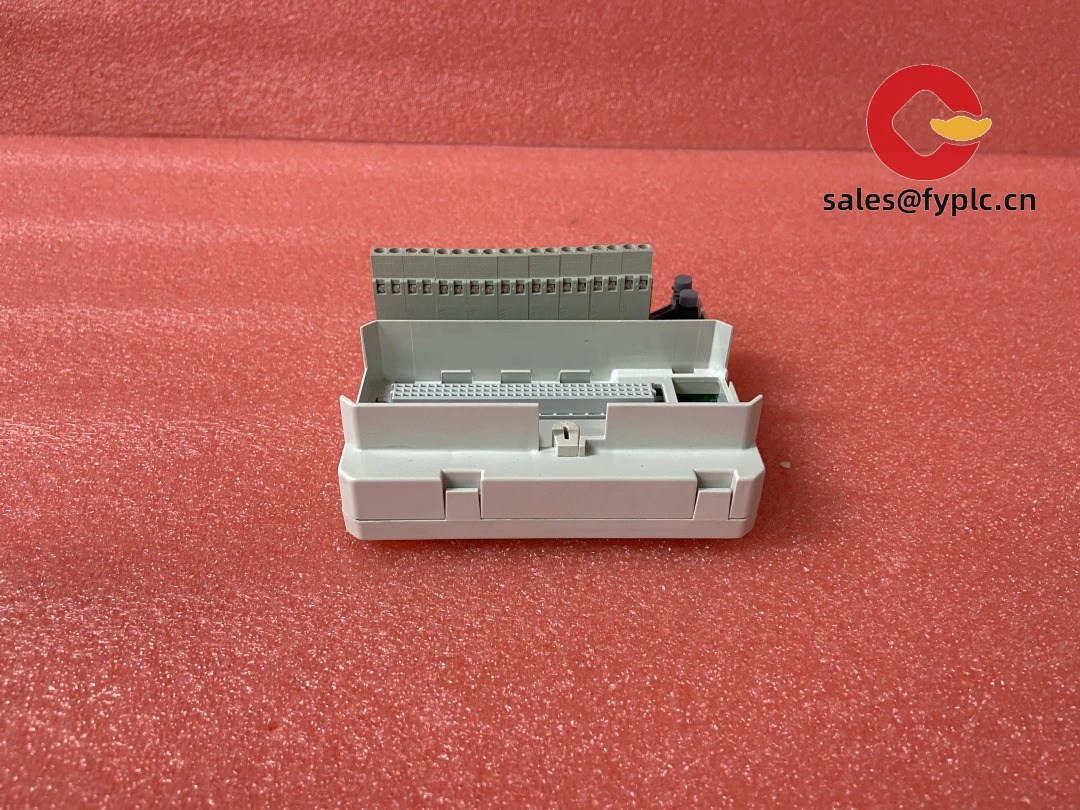

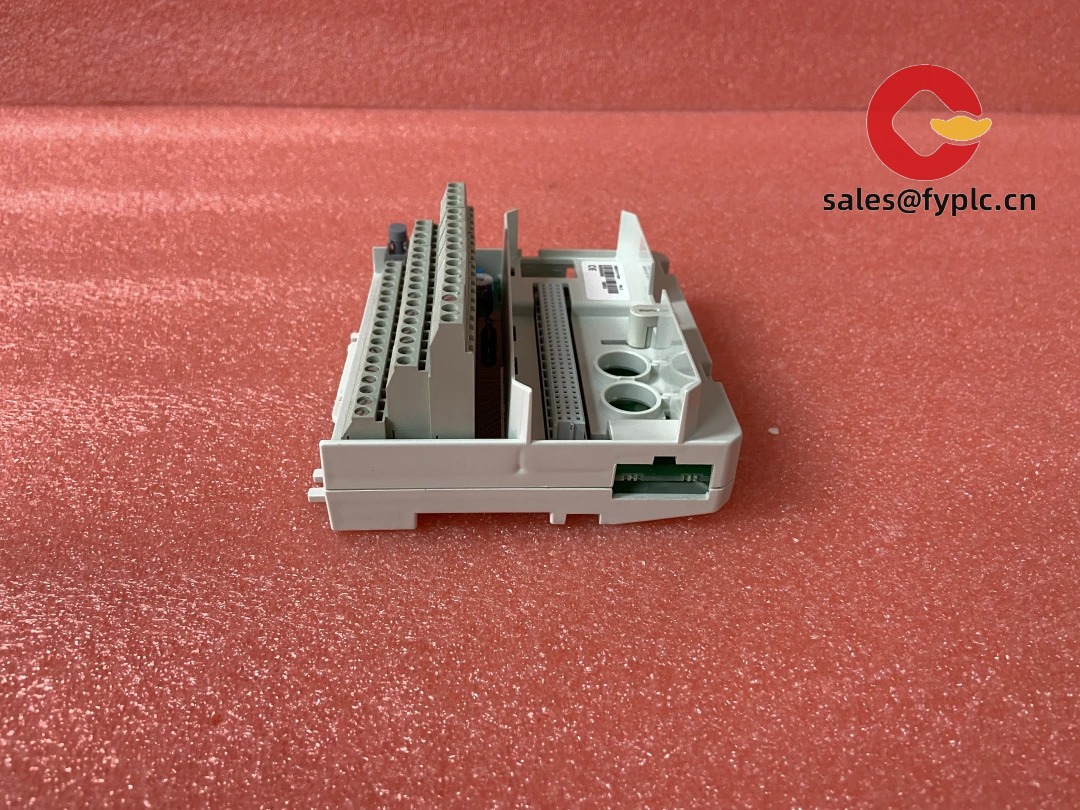

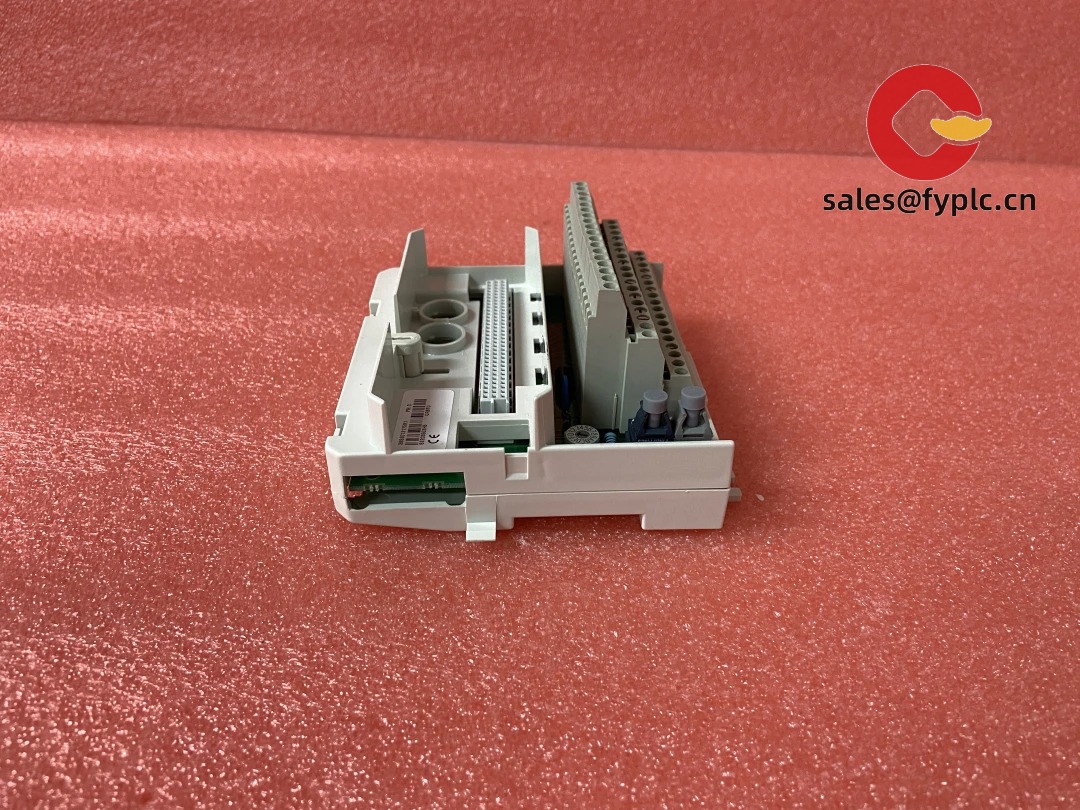

ABB GRBTU 3BSE013175R1: Your Robot Motion Controller’s Reliable Nervous System

If you’re wrestling with robotic motion glitches on assembly lines, this ABB module might be your quiet hero. From my experience troubleshooting automotive welding cells, the GRBTU 3BSE013175R1 handles real-time axis coordination without breaking a sweat – even when ambient temps climb near 50°C in those cramped control cabinets. One plant manager actually told me it cut his robot path recalibration time by nearly 30% after switching from older controllers.

Why It Stays Cool Under Pressure

- Real-time motion control – Typically handles 8-axis coordination with sub-millisecond response. You might notice smoother welding paths on complex chassis components.

- Integrated safety channel – Built-in SIL2-rated safety logic (per IEC 61508) means fewer external relays. Saved a packaging client $2k in panel space last month.

- Hot-swap friendly – Replace it without killing production. One thing I appreciate is how the status LEDs stay lit during module swaps.

- Dual industrial protocols – Speaks both PROFINET and EtherNet/IP natively. In many cases, this avoids protocol gateway headaches in mixed-brand facilities.

Technical Snapshot

| Specification | Details |

|---|---|

| Brand/Model | ABB GRBTU 3BSE013175R1 |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24 V DC ±15%, 1.2 A max |

| Dimensions & Weight | 40 x 100 x 120 mm / 0.8 kg |

| Operating Temperature | -10°C to +55°C (non-condensing) |

| Communication Interfaces | PROFINET, EtherNet/IP, RS-485 (Modbus) |

| Installation Method | DIN rail TS-35/7.5 or panel mount |

Where It Earns Its Keep

You’ll typically find this module buried in robotic cells for auto body shops – think spot welding arms that need microsecond sync across multiple stations. But it’s also sneaking into food packaging lines where motion precision affects seal integrity. One dairy plant actually uses it for robotic palletizing; their maintenance guy swears it survived two coolant floods thanks to the conformal coating. Seems to be particularly resilient in high-vibration environments where cheaper controllers glitch.

Why Procurement Teams Nod Approvingly

Let’s be real – you’re not just buying hardware. That 365-day warranty starts when it ships (not when installed), which matters when your production line can’t wait. Compatibility with ABB’s RobotStudio means your engineers won’t need new training licenses. And from my experience, the real cost saver? Firmware updates via USB stick during lunch breaks instead of hiring third-party specialists. One client avoided $15k in downtime last quarter doing exactly that.

Keeping It Running Smoothly

Mount it in standard IP20 cabinets with at least 50mm clearance on both sides – those aluminum heat sinks need airflow. You’ll want decent cabinet ventilation though, since sustained operation above 50°C does shorten lifespan. Clean dust from the vents quarterly with compressed air (never solvents!), and check terminal torque annually. Pro tip: Schedule firmware updates during planned maintenance; they usually take under 10 minutes. Oh, and always power down before swapping modules – I’ve seen one too many fried ports from hot-plugging.

No-Sweat Guarantees

It’s CE, UL, and ISO 13849-1 certified with RoHS compliance – no customs headaches. That 365-day warranty covers defects in materials/workmanship (excluding physical damage). Delivery? In-stock units ship within a week via DHL/FedEx/UPS – we’ve never gone beyond 3 weeks even for backorders. Payment’s simple: 50% upfront, balance before shipping. Honestly, the most common “issue” we get is clients forgetting to update RobotWare versions – which is why we include free version-check support for the first year.

Reviews

There are no reviews yet.