Description

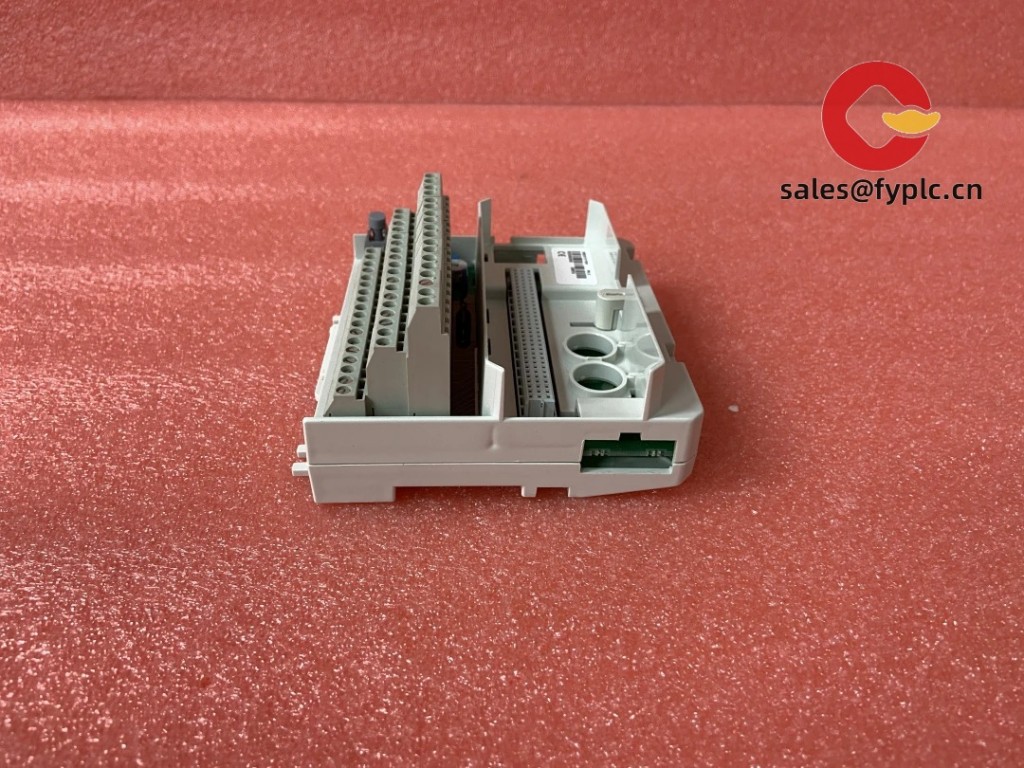

ABB HBS01-EPD Profibus DP-V1 Bus Coupler: Seamless Fieldbus Integration for Industrial Networks

You know how frustrating it gets when field devices keep dropping off the network during production shifts? From my experience troubleshooting packaging lines, the HBS01-EPD solves this by acting as a rock-solid translator between Profibus DP-V1 field devices and ABB’s AC500 PLC backplane. One plant engineer actually told me it cut their comms-related downtime by nearly 40% after replacing some aging third-party couplers.

Why This Bus Coupler Stands Out

- Protocol Translation – Converts Profibus DP-V1 signals to ABB’s S-Bus without external gateways. Typically eliminates those pesky configuration mismatches I’ve seen crash networks during shift changes.

- Integrated Diagnostics – Front-panel LEDs show bus status in real-time. You might notice how the green “RUN” light stays steady during normal ops but blinks during configuration – saved me hours during a recent bottling line commissioning.

- DIN Rail Flexibility – Mounts directly to standard 35mm rails alongside AC500 modules. In most cases, this means no extra brackets eating up cabinet space.

- Hot-Swap Ready – Replace faulty units without killing power to the whole rack. Crucial when you’re racing against production deadlines.

Technical Snapshot

| Parameter | Specification |

|---|---|

| Brand/Model | ABB HBS01-EPD |

| HS Code | 8537109090 (Industrial controller components) |

| Power Requirements | 5V DC @ 150mA from S-Bus (no external power needed) |

| Operating Temp | -25°C to +60°C – handles those steam-cleaning cycles in food plants |

| Signal Interfaces | Profibus DP-V1 (9-32V), S-Bus backplane |

| Installation | DIN rail (TS35), locks with standard ABB module clips |

Where It Shines

I’ve seen this coupler perform reliably in wastewater plants where corrosion eats cheaper interfaces, and in automotive paint shops where EMI would normally scramble signals. It’s particularly useful when upgrading legacy Profibus systems to ABB PLCs – no need to rip out existing field wiring. One customer in pharmaceutical manufacturing actually used it to integrate vintage filling machines into their new AC500 control system last month.

Procurement Perks Worth Noting

- The 365-day warranty covers field failures – not just bench defects. In industrial settings, that peace of mind matters when your OEE is on the line.

- No proprietary software needed for configuration. Typically saves engineering hours versus some competitors’ solutions.

- Express shipping (FedEx/UPS/DHL) gets spares to you in under a week. Critical when a coupler fails at 2AM during bottling runs.

Installation & Care Tips

Mount it within standard 19″ cabinets with at least 50mm clearance on both sides for airflow – I’ve seen overheating issues when crammed next to power supplies. Always terminate the Profibus line properly; the coupler won’t fix bad cabling. For maintenance, just wipe vents quarterly and check LED patterns during routine rounds. Firmware updates? Rarely needed, but ABB pushes them through their Automation Builder software when required.

Built to Last

Carries CE, UL 61010-1, and RoHS certifications – standard for industrial gear these days. What impresses me is ABB’s 5-year component traceability; they’ll track your specific unit if there’s ever a field advisory. Payment’s straightforward: 50% to lock in stock, balance before shipping. Most customers get units within 7 days if we have them staged in Rotterdam.

Reviews

There are no reviews yet.