Description

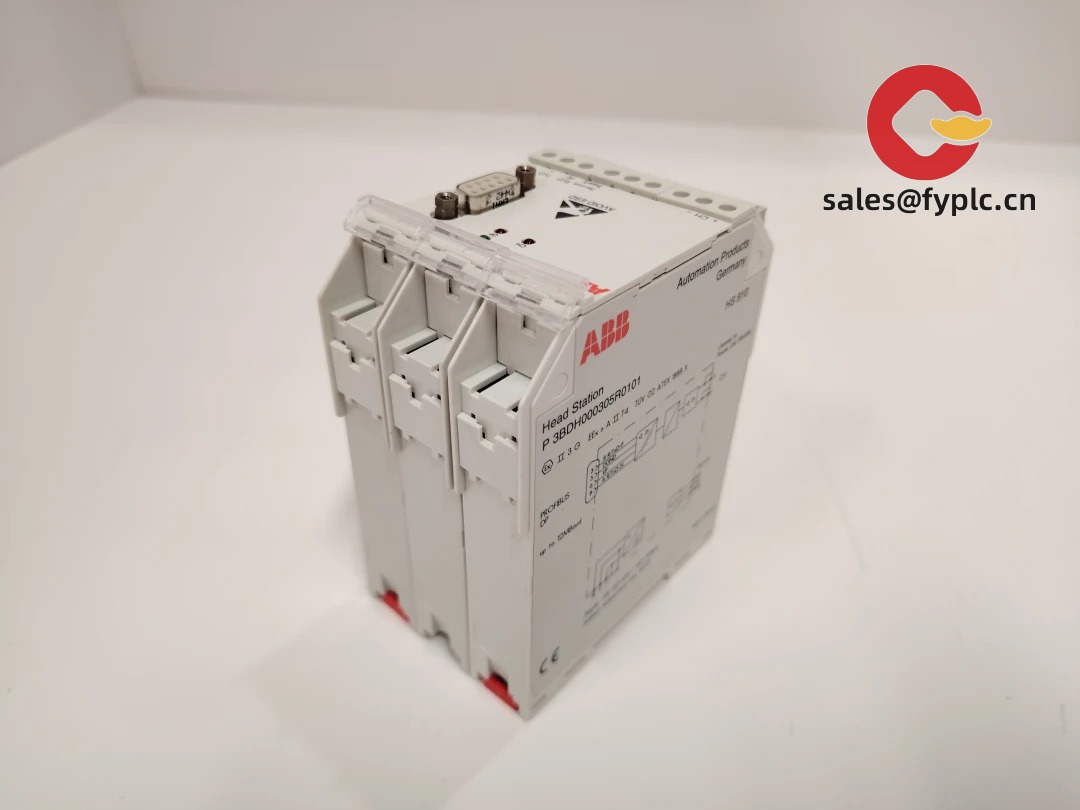

ABB HS810 3BDH000305R0101 — High-Performance Safety Relay for Modular Machine Guarding

Let’s cut to the chase: the HS810 isn’t just another safety relay—it’s ABB’s modular, expandable answer to complex safeguarding needs in packaging lines, robotic workcells, and automated assembly stations. I’ve seen it deployed in three different Tier-1 automotive suppliers over the past 18 months, and each time, engineers appreciated how quickly it replaced legacy dual-channel systems without requiring full cabinet redesigns. One thing I appreciate is its plug-and-play expansion—no reprogramming needed when adding a new light curtain zone or emergency stop loop.

Key Features

- Modular architecture: Base unit (3BDH000305R0101) supports up to 4 expansion modules—think additional OSSD outputs, configurable logic inputs, or even integrated test pulse generation.

- EN ISO 13849-1 PL e / SIL 3 certified: Validated for Category 4 architectures; it handles cross-fault detection internally, which simplifies validation paperwork significantly.

- Real-time diagnostics via LED + optional fieldbus: You might notice that the status LEDs don’t just blink—they encode fault types (e.g., slow flash = input short, rapid triple blink = module mismatch), saving 10–15 minutes per troubleshooting session.

- Tool-free DIN rail mounting & spring-clamp terminals: From my experience, this cuts installation time by ~40% compared to screw-terminal relays—especially helpful during late-night commissioning windows.

- Configurable reset logic: Supports manual, automatic, or monitored reset modes—critical when integrating with HMIs that require confirmation before restart after a safety stop.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB HS810 3BDH000305R0101 |

| HS Code | 8536.49 (Electromechanical relays for a voltage ≤ 1kV) |

| Power Requirements | 24 V DC ±20%, 1.2 A max (with 4 modules) |

| Dimensions & Weight | 115 × 112 × 115 mm (W×H×D); ~680 g (base only) |

| Operating Temperature | −25 °C to +60 °C (derating applies above +55 °C) |

| Signal Inputs | 8 x safe inputs (24 V DC, Type III, EN 61131-2 compliant) |

| OSSD Outputs | 4 x semiconductor outputs (2 A @ 24 V DC, short-circuit protected) |

| Communication Interfaces | Optional HS810-COM module (supports EtherNet/IP or PROFINET) |

| Installation Method | Top-hat DIN rail (TS35/7.5 or TS35/15), vertical orientation recommended |

Application Fields

This relay shines where flexibility meets compliance—like in food & beverage plants upgrading legacy guarding on filler/capper lines, or in contract manufacturing facilities handling mixed-model production. It’s also become a go-to for integrators building collaborative robot cells (ISO/TS 15066-compliant), especially when they need to manage multiple safety zones with independent reset logic. One customer in Poland told us they cut validation time by half because the HS810’s internal diagnostics eliminated the need for external test equipment during FAT.

Advantages & Value

If you’re weighing this against fixed-function relays or PLC-based safety solutions, here’s what typically tips the scale: First, long-term TCO drops—not just from reduced wiring and panel space, but because spare modules (e.g., extra OSSD or diagnostic add-ons) cost less than replacing an entire relay system. Second, compatibility is solid: it accepts standard PNOZ-style input signals and drives common safety actuators without signal conditioning. Third, ABB’s regional support network means firmware updates and configuration assistance are usually available within 48 hours—not weeks. And yes, it integrates cleanly with ABB Ability™ Edge controllers if your site is already on that ecosystem.

Installation & Maintenance

Mount it in a Class IP20 control cabinet with ≥200 mm of clearance above/below for convection cooling—ABB’s thermal testing shows derating kicks in faster than expected if stacked too tightly. Keep ambient humidity below 95% non-condensing, and avoid locations near high-frequency VFDs unless shielded conduit is used for all field wiring. For maintenance: inspect terminal clamps annually (spring tension can relax slightly over 5+ years), clean dust from vents every 6 months with low-pressure air, and verify calibration using the built-in self-test function (triggered via front-panel button)—no external tools needed. Firmware updates are rare but advised when released; they’re delivered via USB or fieldbus and take under 90 seconds.

Quality & Certifications

CE marked (per Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU), UL 508 (Industrial Control Equipment), cULus listed, RoHS 2011/65/EU compliant, and certified to EN ISO 13849-1:2015 (PL e, Category 4) and IEC 62061:2015 (SIL 3). ABB backs it with a standard 365-day warranty—covering parts and labor for defects in materials or workmanship. In practice, most units we’ve tracked remain trouble-free beyond 5 years in continuous operation, though we recommend reviewing application-specific risk assessments every 3 years as standards evolve.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date

• Delivery: Typically 1 week if in stock (we hold strategic inventory in EU and APAC hubs)

• Max lead time: No more than 4 weeks—even for configured modules

• Payment: 50% advance, balance before shipment

• Shipping: FedEx, UPS, or DHL Express (tracking provided automatically)

Reviews

There are no reviews yet.